A kt board forming machine

A forming machine and board core technology, applied in lamination auxiliary operations, chemical instruments and methods, lamination, etc., can solve the problem of uneven surface of KT board, non-adhesive board core adhesive tape, and easy torn adhesive tape, etc. problem, to achieve good hot pressing effect, good product quality, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

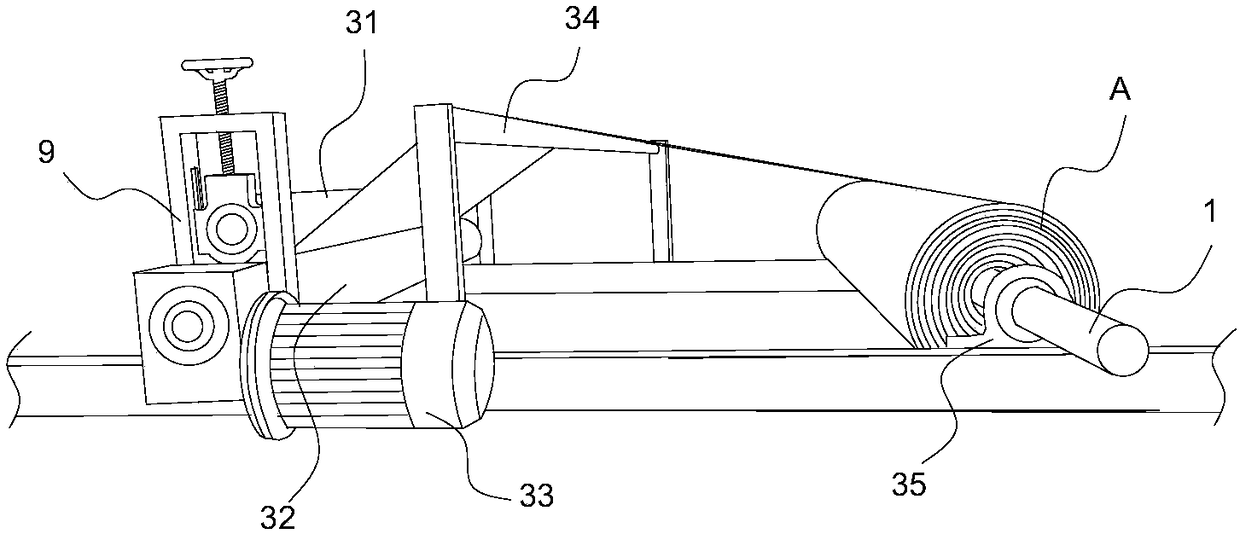

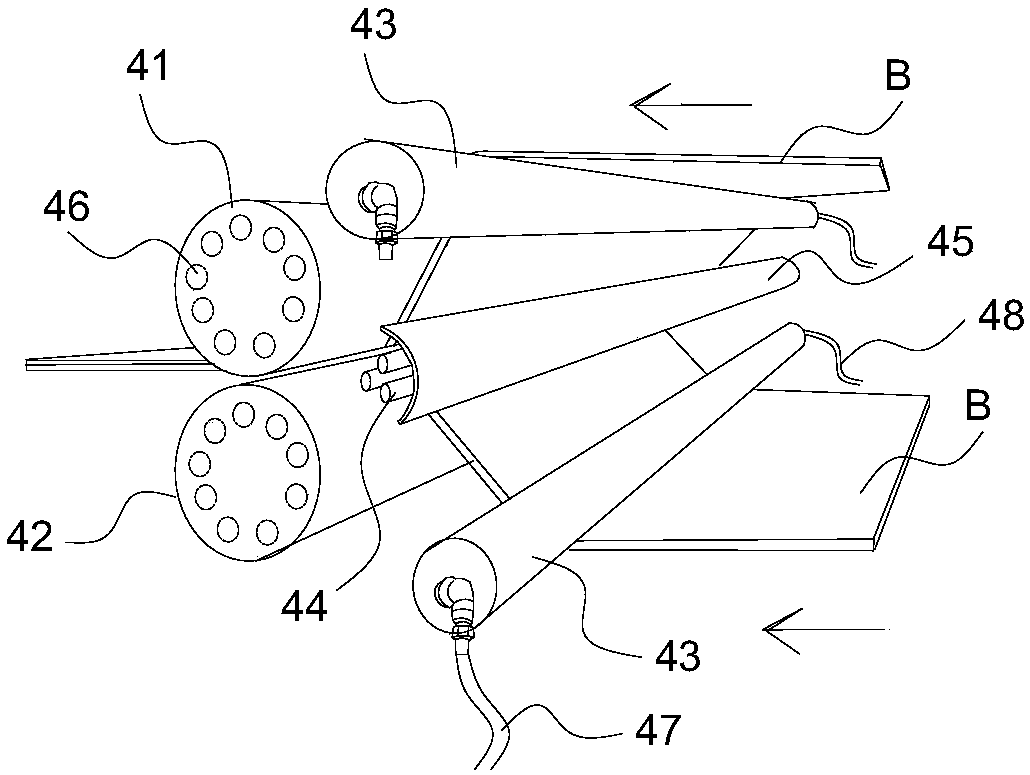

[0037] Such as Figure 1-9 As shown, a KT board forming machine includes two tape rolls 1 with tape A, two core rolls 2 with core B, and a tape conveyor for controlling the speed of tape transfer. Device 3, the first hot-pressing device 4 for hot-pressing two board cores to form a composite board core, the second hot-pressing device 5 for sticking adhesive tape on the upper and lower surfaces of the composite board core, and the KT Cooling device 7 for board cooling, cutting device 8 for cutting and forming the cooled and formed KT board; the two board cores are hot-pressed and laminated, glued, cooled and cut in sequence to obtain the KT board.

[0038] The tape conveying device 3 includes an upper roller 31 and a lower roller 32 for clamping and conveying the tape at a constant speed, a motor 33 for controlling the rotation speed of the lower roller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com