Centralized liquid feeding system for mining area

A technology for liquid supply and mining area, which is applied in mining equipment, earthwork drilling, neutralization water/sewage treatment, etc. It can solve the problems of reducing the working stability of the hydraulic system, affecting the performance of the emulsion pump, and the safety hazards of the hydraulic support. , to achieve the effect of improving the quality of liquid supply, saving power resources, ensuring performance and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

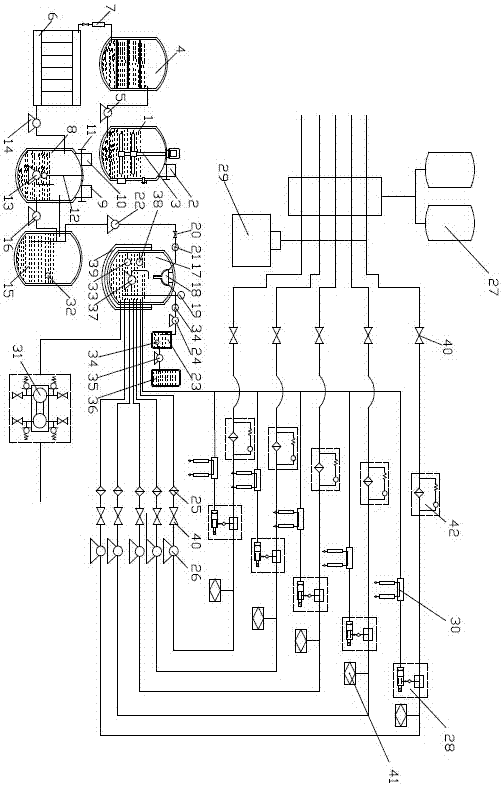

[0020] like figure 1 As shown, a centralized liquid supply system for a mining area proposed by the present invention includes: a water purification device, a liquid distribution device, a liquid supply device and a controller; the water purification device is used to purify mine water to obtain clear water, and the liquid distribution device It is used to mix emulsified oil and clear water to obtain emulsion, and the liquid supply device is used to transport the emulsion to the hydraulic system of the support of the working face; the controller is used to control the work of the water purification device, liquid distribution device and liquid supply device;

[0021] The water purification device includes a flocculation pretreatment device 1, a filter device 4, a water softening device 6, a pH adjustment device 8 and a water storage device 15; the flocculation pretreatment device 1 has a mine water inlet, and a flocculant tank 2 and a stirring mechanism are arranged on it 3. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com