Connection system and method of plug-and-play shelf label network

A shelf label, plug-and-play technology, applied in the field of the Internet of Things, can solve problems such as excessive label installation space, high media cost, and networking failures, and achieve the effects of simple and reasonable overall structure, simplified production process, and reduced media cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

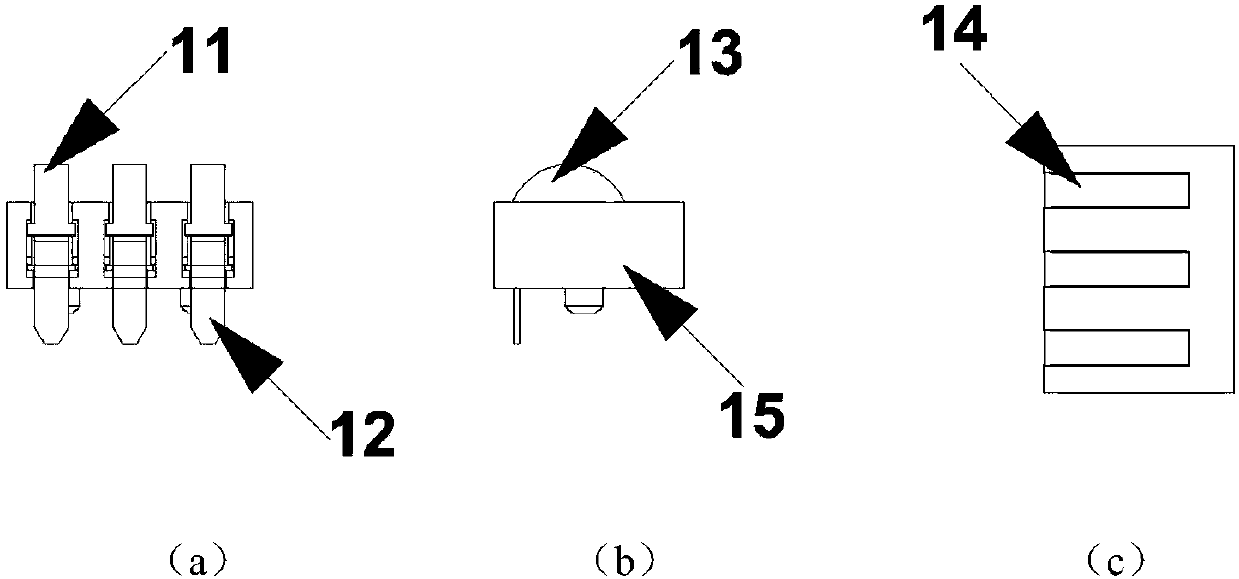

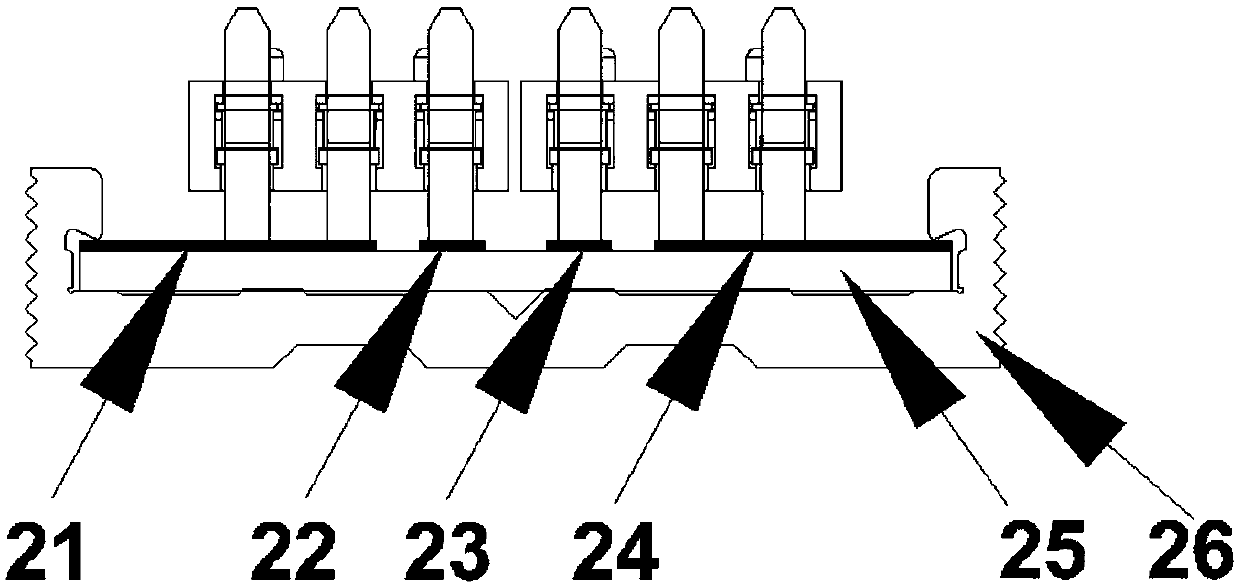

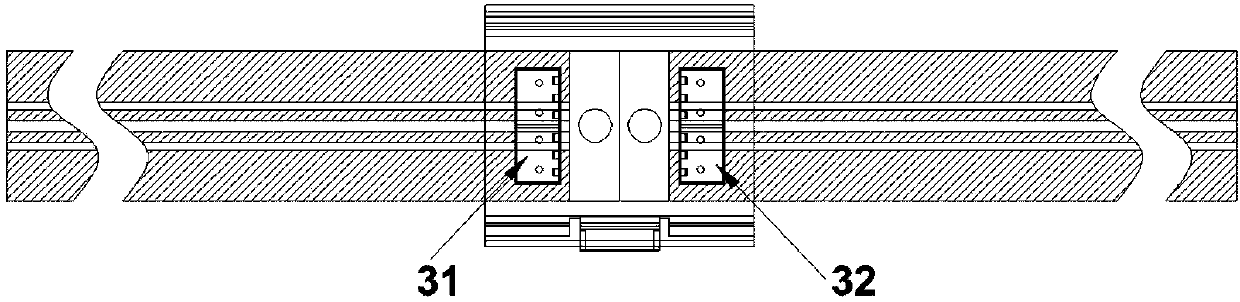

[0044] According to the plug-and-play shelf label network connection system provided by the present invention, the shelf label network connection system includes: the conductive contact rail assembly of the bus bar ( figure 2 ), a jumper and a terminator, the conductive contact structure of the busbar is installed in the shelf guide rail substrate, the two busbars are connected by a jumper, and between the layers of the shelf, the shelf and the shelf Between them are connected to the main network throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com