Aluminum-coated steel-core heatproof aluminum alloy twisted wire with self damping, low loss and high strength

A technology of aluminum clad steel core and aluminum clad steel wire, which is applied to the parts of the conductive core, power cables, conductors, etc., can solve the problems of high power loss, wire fatigue and broken strands, and whole wire breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

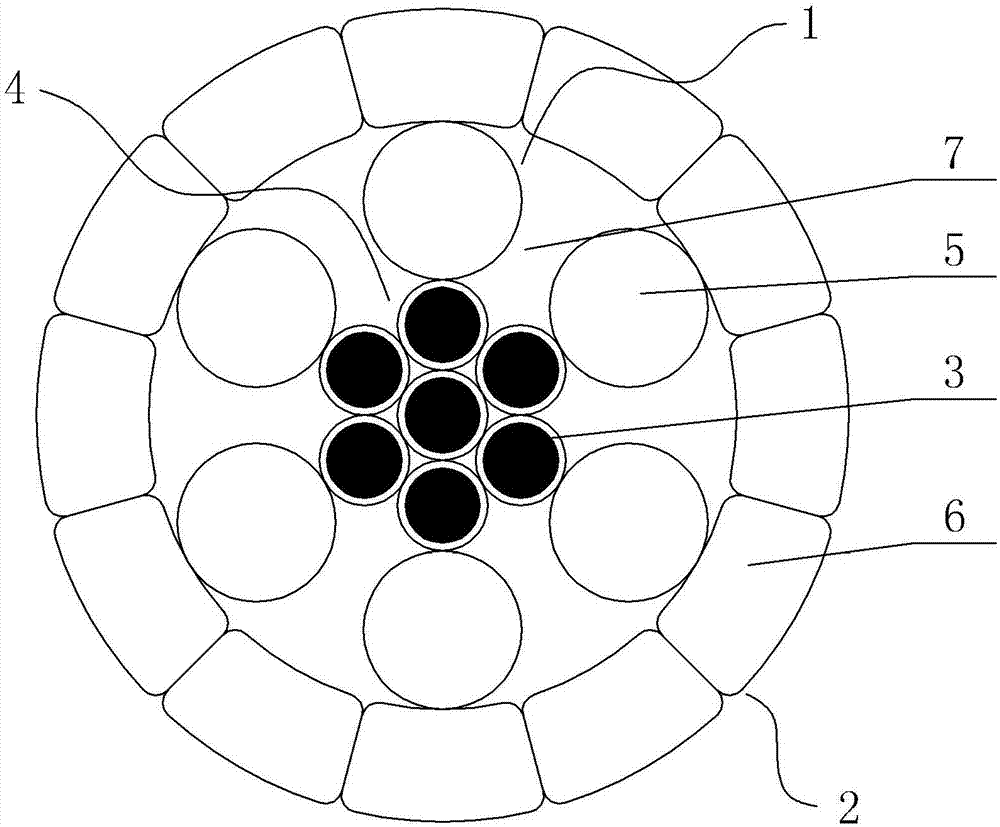

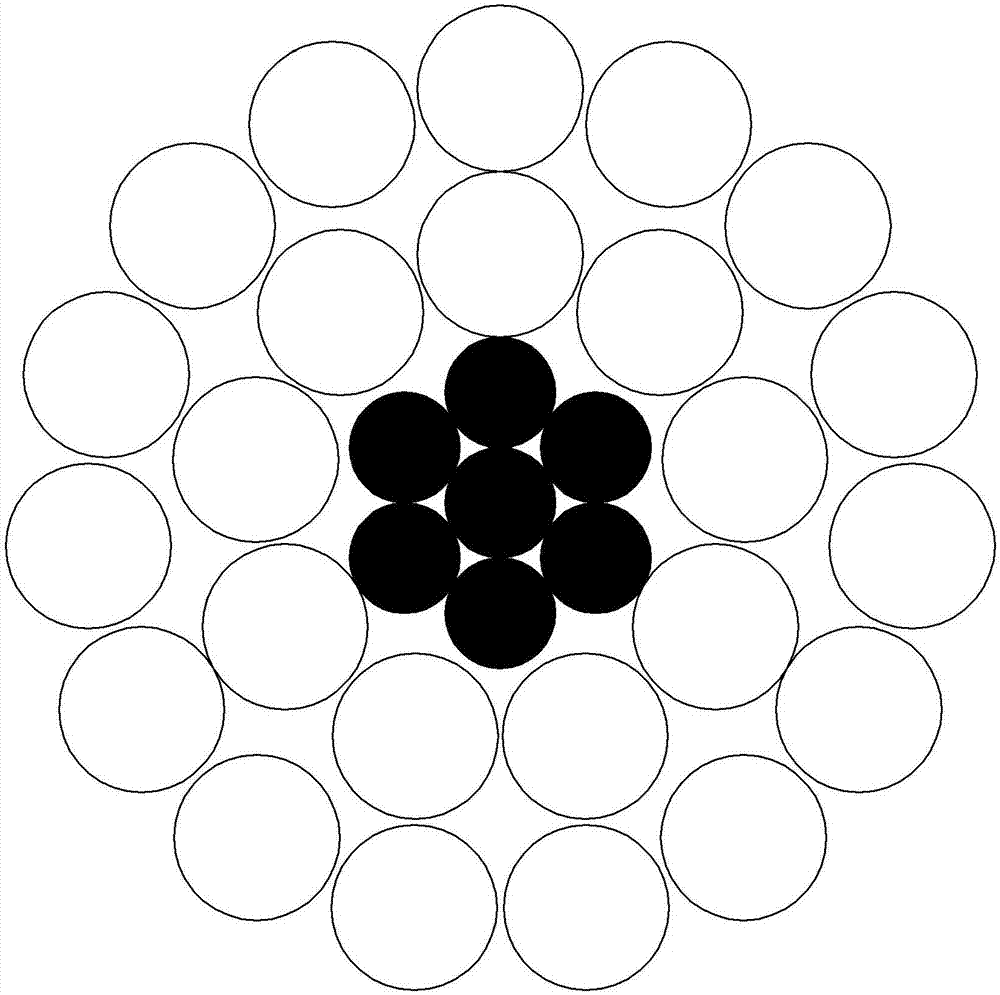

[0029] Specific embodiment: the load-bearing reinforcement core 4 is specifically a load-bearing reinforcement core formed by concentrically twisting 1+6 aluminum-clad steel wires 3; An inner conductor layer 1 composed of circular cross-section aluminum strands, on which an outer conductor layer 2 consisting of twelve trapezoidal cross-section aluminum strands 6 is concentrically twisted.

[0030] Under the condition that the conductive cross-section remains unchanged, the inner layer adopts a split structure to reduce the cross-section of the inner conductor layer, while the outer layer adopts a profiled structure, which effectively increases the conductive cross-section of the outer conductor layer and reduces the AC resistance caused by AC transmission; The G1A-strength galvanized steel core is replaced by a high-strength aluminum-clad steel core with an equal cross-section close to G3A strength and a conductivity of 20.3% IACS. Calculated DC resistance will be below figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com