Environment-friendly thermal power unit system

A thermal power unit, environmental protection technology, applied in the direction of general control system, control/regulation system, electrical program control, etc., can solve the problems of unable to realize sulfur dioxide emission, large investment in equipment, etc., achieve the effect of optimizing environmental protection indicators and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

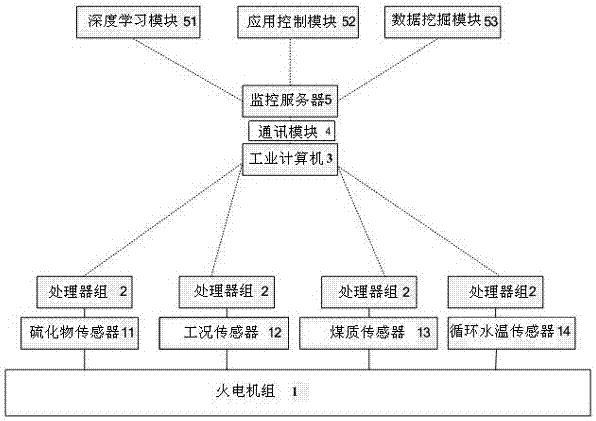

[0023] A kind of environment-friendly thermal power unit system, its structure is as follows figure 1 Shown, comprise thermal power unit, sensor group, processor group, industrial computer 3 and monitoring server 5, sensor group is arranged in thermal power unit, the output end of sensor group connects the input end of processor group, and processor group passes industrial computer and The monitoring servers communicate with each other.

[0024] The sensor group is used to collect the key data of the thermal power unit, and transmit the collected data to the processor group. The sensor group includes a sulfide sensor 11 , a working condition sensor 12 , a coal quality sensor 13 and a circulating water temperature sensor 14 . The sulfide sensor 11 is installed on the sewage outlet of the thermal power unit to monitor the content of sulfur dioxide; the working condition sensor 12 is arranged in the thermal power unit to monitor whether the thermal power unit is in a stable work...

Embodiment 2

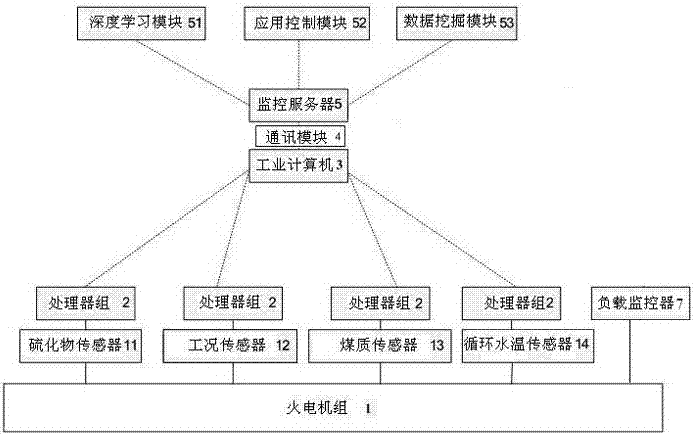

[0029] The structure of this embodiment is as figure 2 As shown, the difference from Embodiment 1 is that a load monitor 7 is also provided in the thermal power unit, and the load monitor is a dynamic load monitor. At the same time, the deep learning module of the monitoring server is provided with a load optimization unit 511 for processing the data reflected by the dynamic load monitor and forming an optimization parameter group related to load distribution.

[0030] In this embodiment, the deep learning module 51 performs fitness calculation according to the coal consumption-load curve, takes coal consumption as the objective function of load optimization distribution, and optimizes the model to achieve convergent coal consumption characteristic parameters through the iterative calculation of the parent and child generations , and set the upper and lower limits and balance constraints of each generator set, comprehensively consider the power generation requirements of each...

Embodiment 3

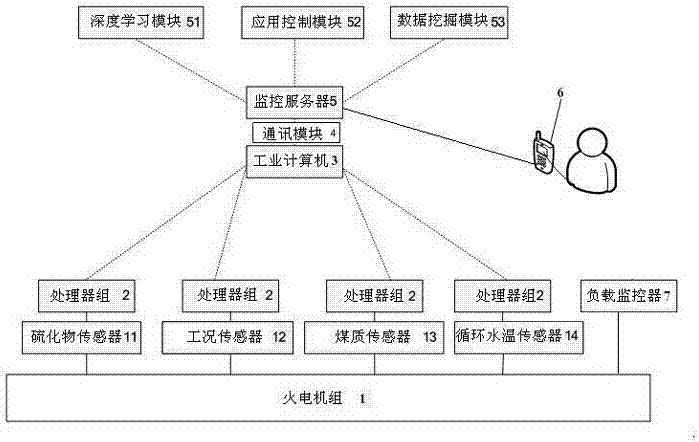

[0033] The structure of this embodiment is as image 3 As shown, the difference from Embodiment 2 is that the monitoring server is also connected to the application parent terminal 6 through the wireless network, and the application parent terminal is installed in the smart mobile device. The application control module 52 of the monitoring server is set in order to cooperate with the parent terminal of the application. The monitoring server can send the environmental protection curve and optimization parameters to the parent terminal of the application in a graphical manner. The status of the unit is adjusted in real time through the industrial computer.

[0034] The parent terminal of the application in this embodiment can realize real-time display, real-time alarm, and has the function of issuing adjustment parameter commands for certain parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com