Distributing system and method for flue gas desulfurization and denitrification activated carbon

A technology of desulfurization and denitrification and distribution system, which is applied in the field of flue gas desulfurization and denitrification activated carbon distribution system and distribution, and flue gas treatment equipment. It can solve the problems of waste, fluctuation of flue gas volume and pollutant difficulty, and unscientific problems, so as to reduce operating costs , the movement speed is reduced, and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

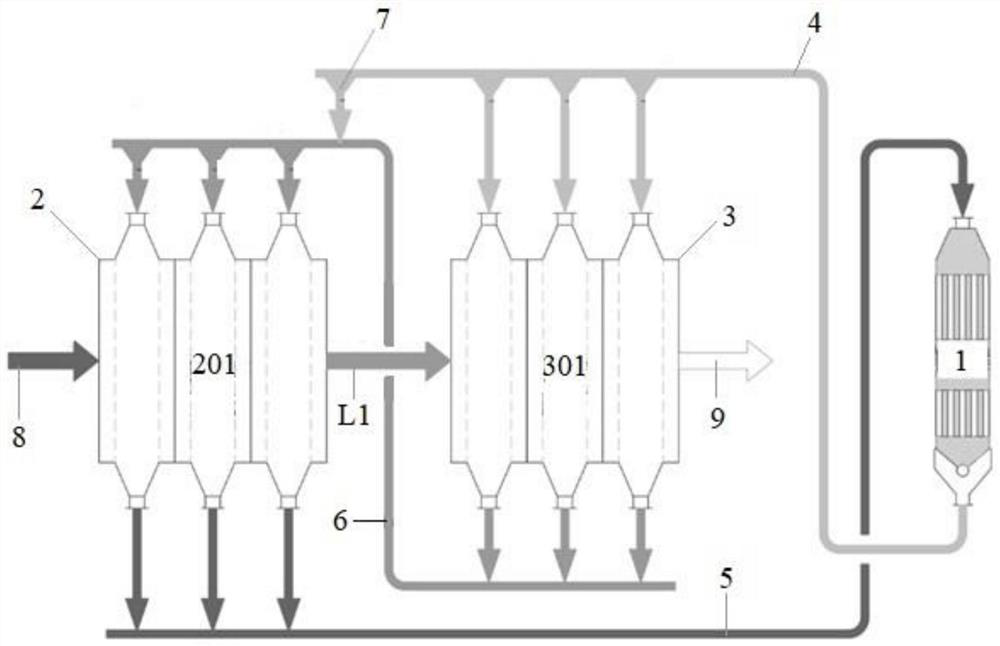

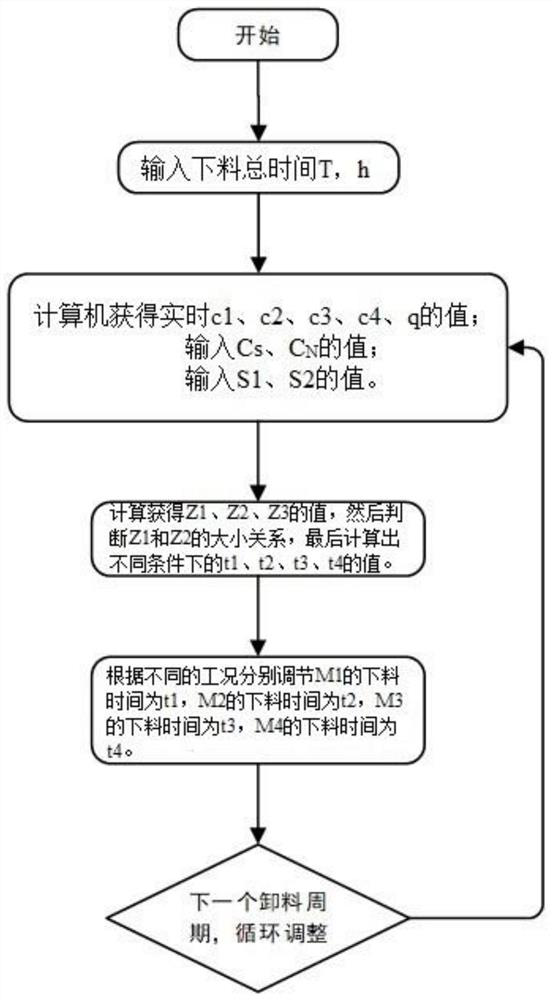

[0082] Such as figure 1 As shown, an activated carbon distributing system for flue gas desulfurization and denitration, the system includes a desorption tower 1, a desulfurization tower 2, and a denitration tower 3. According to the direction of the flue gas, the raw flue gas inlet pipe 8 is connected with the air inlet of the desulfurization tower 2 . The exhaust port of the desulfurization tower 2 is connected with the air inlet port of the denitrification tower 3 through the first pipeline L1. The exhaust port of the denitrification tower 3 is connected with the clean flue gas exhaust pipe 9 . The discharge port of the desorption tower 1 is connected with the feed port of the denitrification tower 3 through the first activated carbon conveying device 4 . The discharge port of the desulfurization tower 2 is connected with the feed port of the desorption tower 1 through the second activated carbon conveying device 5 . The discharge port of the denitrification tower 3 is co...

Embodiment 2

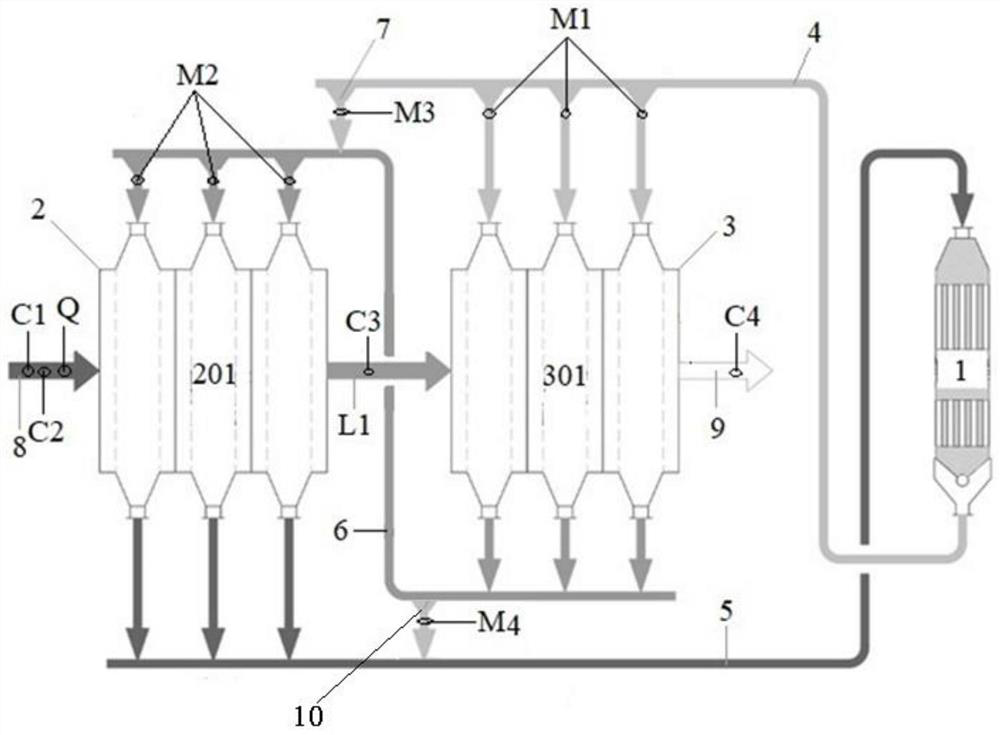

[0084] Example 1 is repeated, except that a second bypass activated carbon delivery device 10 is provided upstream of the third activated carbon delivery device 6 , and the second bypass activated carbon delivery device 10 is connected to the second activated carbon delivery device 5 .

Embodiment 3

[0086] Repeat Example 2, except that the desulfurization tower 2 is provided with three desulfurization units 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com