Carbon dioxide concentration calibration modification device and calibration modification method

A carbon dioxide and calibration device technology, which is applied in the direction of measuring devices, standard gas analyzers, instruments, etc., can solve the problems of zero point drift, complex disassembly or reinstallation process, and large quantity, so as to prolong the service life and reduce the aging degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

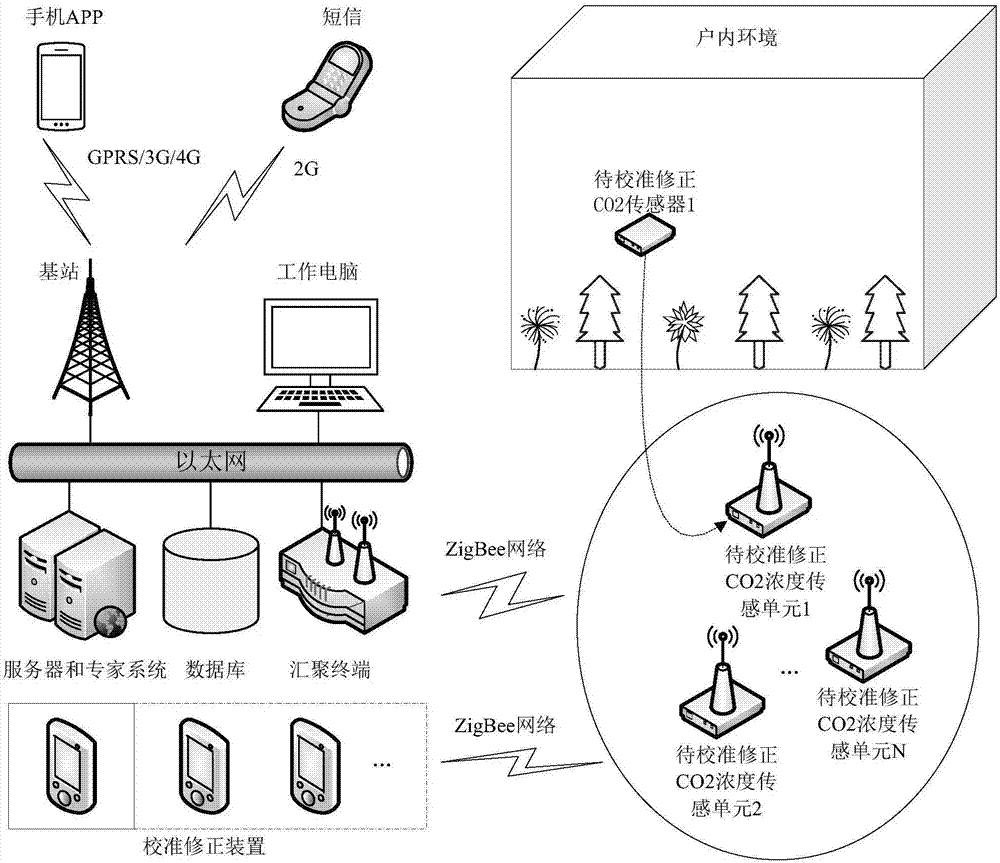

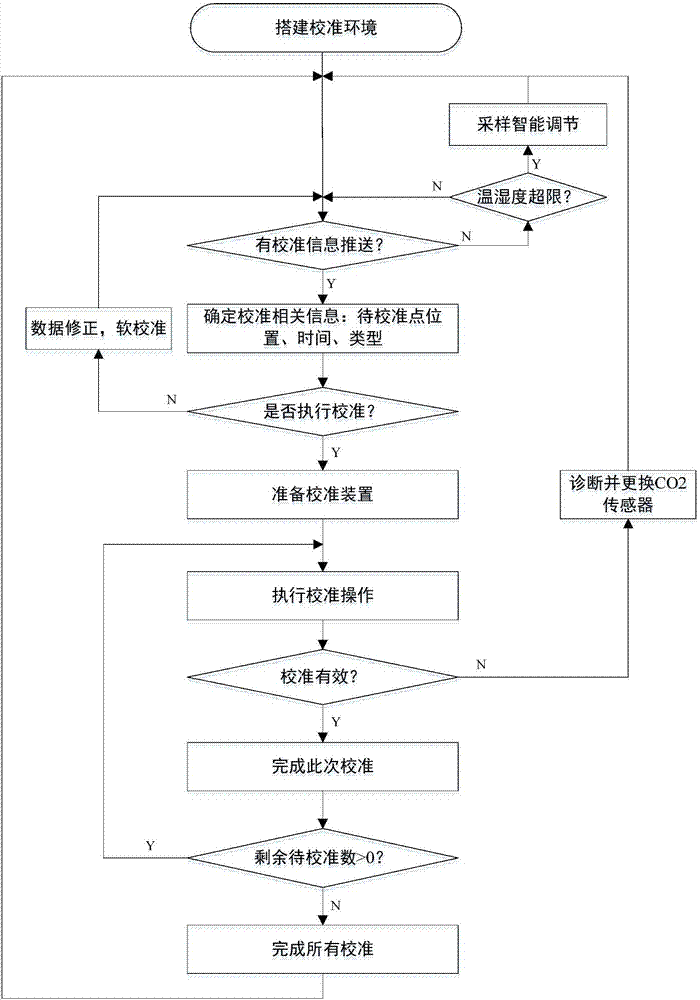

[0051] A carbon dioxide concentration calibration correction device and its correction method provided in this embodiment, combined with the actual scene of the project, the CO 2 The installation points of the concentration sensor are respectively set in: the glass greenhouse, the south four-span greenhouse, the bird's nest greenhouse, the north four-span greenhouse, the poultry house and the pig house. Moreover, these collection nodes are equipped with temperature and humidity sensors, and realize CO through the ZigBee network. 2 Transparent transmission and aggregation of sensory data such as concentration.

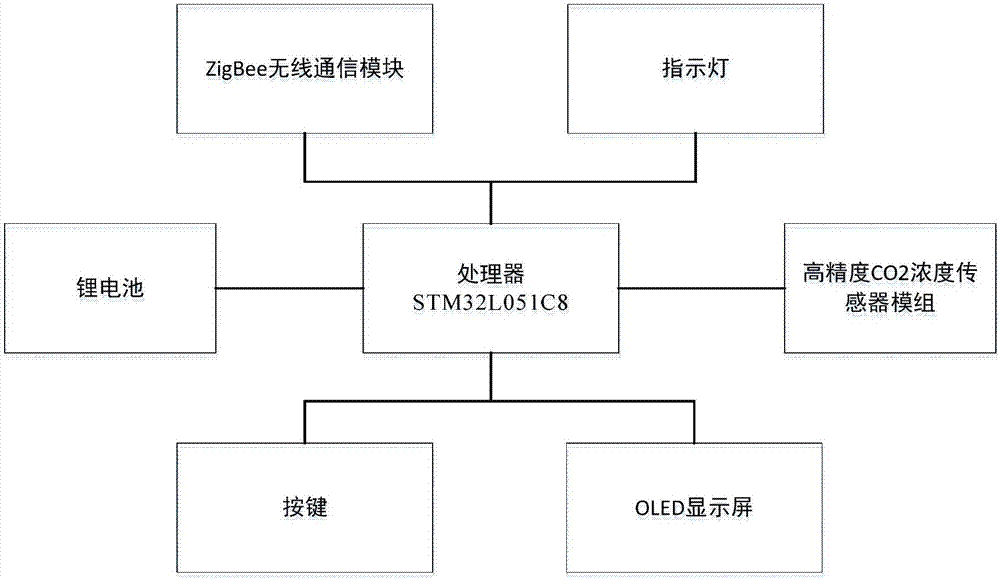

[0052] The carbon dioxide concentration calibration correction device comprises at least one calibration correction device,

[0053]The calibration correction device includes a calibrated carbon dioxide concentration sensor, MCU, a display device composed of a display screen and an indicator light, a combination button and a wireless communication module; among them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com