Online monitoring system and method of heat transfer coefficient and fouling resistance of steady heat exchange process

A technology of heat transfer coefficient and fouling thermal resistance, which is applied in the field of on-line monitoring system for heat transfer coefficient and fouling thermal resistance value in steady-state heat exchange process. Not necessarily representative, etc., to achieve the effect of low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

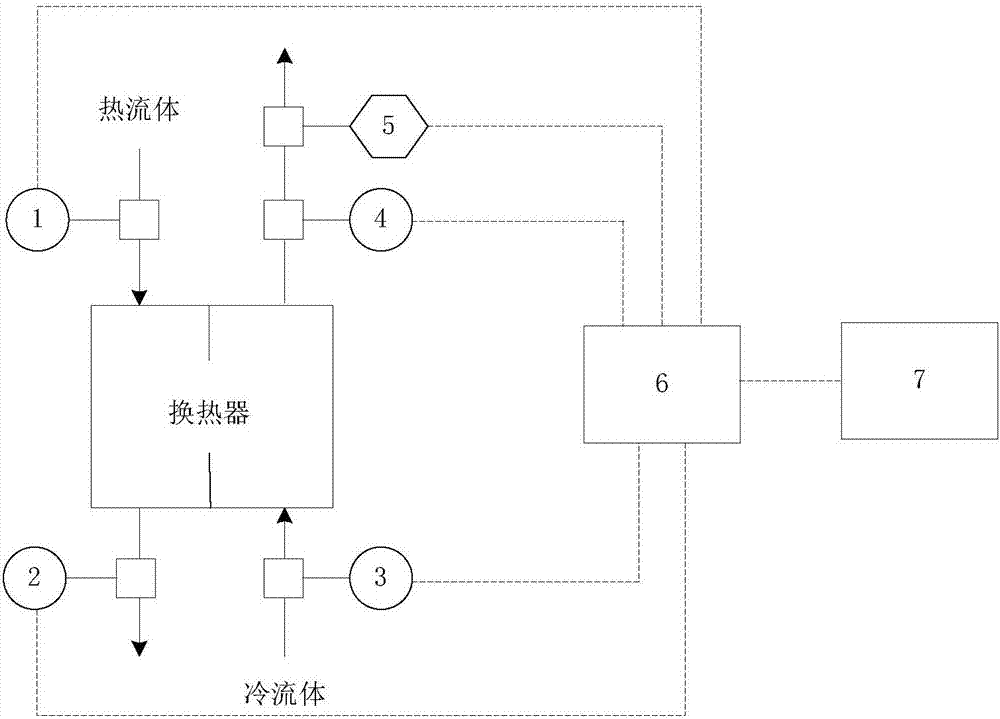

[0056] An online monitoring system for heat transfer coefficient and fouling thermal resistance value in a steady-state heat transfer process, comprising: a first temperature sensor 1, a second temperature sensor 2, a third temperature sensor 3, a fourth temperature sensor 4, a flow meter 5, a central Processor 6 and display 7, its schematic diagram sees figure 1 ;

[0057] Among them, the first temperature sensor 1 is set at the inlet end of the hot side of the heat exchanger, the second temperature sensor 2 is set at the outlet end of the hot side of the heat exchanger, the third temperature sensor 3 is set at the inlet end of the cold side of the heat exchanger, and the fourth temperature sensor The sensor 4 is arranged at the outlet end of the cold side of the heat exchanger, and a flow meter 5 is also arranged at the outlet end of the cold side, the first temperature sensor 1, the second temperature sensor 2, the third temperature sensor 3, the fourth temperature sensor 4...

Embodiment 2

[0089] An online monitoring system for heat transfer coefficient and fouling thermal resistance value in a steady-state heat transfer process, comprising: a first temperature sensor 1, a second temperature sensor 2, a third temperature sensor 3, a fourth temperature sensor 4, a flow meter 5, a central Processor 6 and display 7, its schematic diagram sees figure 1 ;

[0090] Among them, the first temperature sensor 1 is set at the inlet end of the hot side of the heat exchanger, the second temperature sensor 2 is set at the outlet end of the hot side of the heat exchanger, the third temperature sensor 3 is set at the inlet end of the cold side of the heat exchanger, and the fourth temperature sensor The sensor 4 is arranged at the outlet end of the cold side of the heat exchanger, and a flow meter 5 is also arranged at the outlet end of the cold side, the first temperature sensor 1, the second temperature sensor 2, the third temperature sensor 3, the fourth temperature sensor 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com