Anti-shock lift check valve

A lift-type, anti-shock technology, applied to valve details, valve devices, control valves, etc., can solve the problems of easy damage to the sealing surface of the valve disc and valve seat, high noise, and impact on service life, and achieve low noise , Long service life, small impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

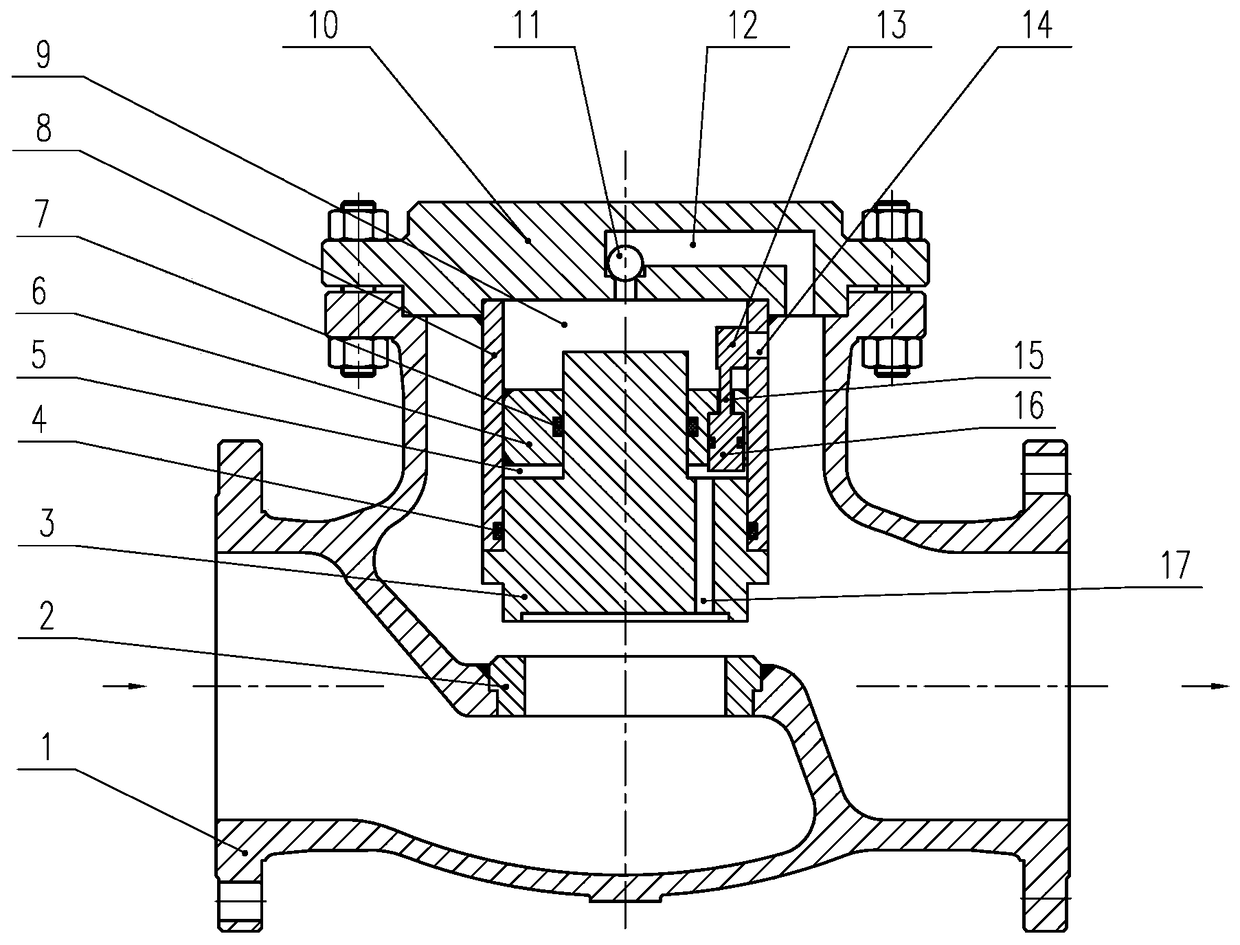

[0018] according to figure 1 , figure 2 It can be seen that the anti-shock lifting check valve of the present invention includes: a valve body 1, a valve seat 2, a valve cover 10 and a guide sleeve 8, the valve body 1 is provided with an inlet flow channel, an outlet flow channel and a middle chamber, and the outlet flow channel and the The middle cavity is connected, the valve seat 2 is set at the outlet end of the inlet flow channel, the upper end of the valve seat 2 is provided with a valve seat sealing surface, the valve cover 10 is fixedly installed at the upper end of the middle part of the valve body 1, and the upper end of the guide sleeve 8 is fixedly installed at the lower end of the valve cover 10. The inside of the guide sleeve 8 is provided with a guide cavity, and the lower end of the guide sleeve 8 extends into the middle cavity. The inside of the guide sleeve 8 is provided with an isolation block 6, and the outer circle of the isolation block 6 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com