Centrifugal type slurry pump

A centrifugal and slurry technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of large cooling water consumption, increased wastewater treatment pressure, increased environmental protection costs, etc., to improve sealing safety , Reduce frictional resistance, effective cooling function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

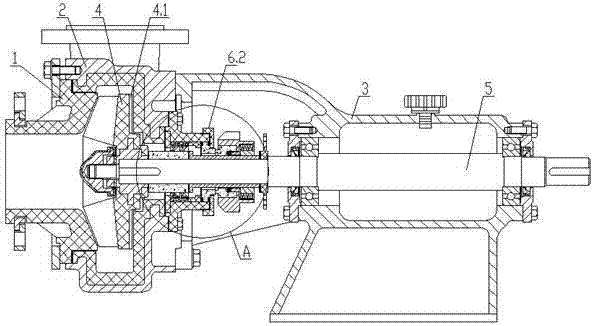

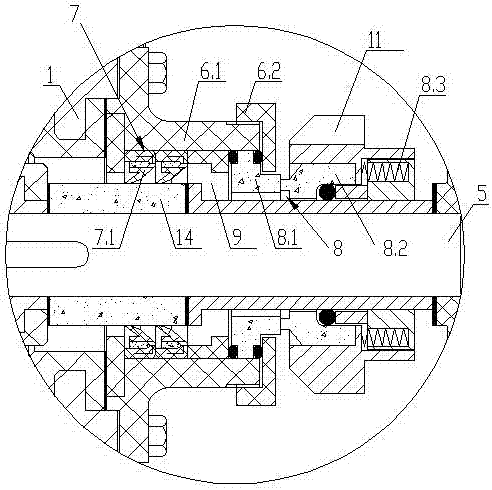

[0042] Embodiment 1: see Figure 1~9 , a centrifugal slurry pump, the slurry pump is a front suction type, including a pump cover 1 with an open front end, a pump casing 2 connected to the pump cover 1, a bearing seat 3 connected to the pump casing 2, and a The impeller 4 in 2 is connected with the impeller 4 to the rotating main shaft 5, and the rotating main shaft 5 protrudes out of the pump casing 2 to connect with the bearing seat 3. A shaft seal is provided at the contact between the rotating main shaft 5 and the pump casing 2, and the shaft sealing includes connection with the pump casing 2. The sealing box 6.1, the sealing box gland 6.2, the main seal 7 on the side of the pump casing 2, the auxiliary seal 8 on the rear side of the main seal 7, the auxiliary seal 8 is an external mechanical seal, and the external mechanical seal includes a static ring 8.1, a dynamic Ring 8.2 and metal spring 8.3, static ring 8.1 are compressed by the sealing box gland 6.2, the main seal ...

Embodiment 2

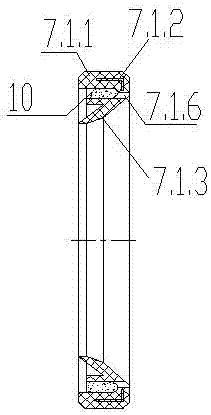

[0044] Example 2: see Figure 10 , 11 , a centrifugal slurry pump, the slurry pump is a side suction type, including a pump cover 1 sealed at the front end, a pump casing 2 connected to the pump cover 1, a bearing seat 3 connected to the pump casing 2, and a The impeller 4 in 2 is connected with the impeller 4 to the rotating main shaft 5, and the rotating main shaft 5 extends out of the pump casing 2 to connect with the bearing seat 3. A shaft seal is provided at the contact between the rotating main shaft 5 and the pump casing 2, and the shaft sealing includes a sealing box 6.1, Seal box gland 6.2, main seal 7 on the side of the pump casing 2, secondary seal 8 on the rear side of the main seal 7, the secondary seal 8 is a mechanical seal, the pump casing 2 is connected to the suction tee 13, and the shaft sleeve 14 is set on the rotating On the main shaft 5, the main seal 7 is composed of two lip seal rings 7.1 superimposed, the lip seal ring 7.1 is a seal ring with a filte...

Embodiment 3

[0058] Embodiment 3: (see Figure 12 , 13 ) The net liquid in the net liquid chamber 9 in the combined seal of the centrifugal slurry pump described in Embodiments 1 and 2 can be obtained and replenished from the external filling liquid port 6.1.1 on the sealing box 6.1 (such as Figure 12 ). The centrifugal slurry pump with this sealing structure can be applied to the post of conveying thick slurry, and a small amount of net liquid can be injected into the pump cavity from the lip and through passage of the rubber lip seal ring to flush the sealing part, as long as a small amount of water is consumed It can also have better sealing cooling and flushing effect.

[0059] In order to flush out the slurry particles entering the liquid chamber due to the failure of the lip seal ring, a better method is to set the slag discharge port 6.1.2 on the lower side of the seal box (such as Figure 13 ), for easy flushing and maintenance.

[0060]In the above embodiment, the liquid inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com