Oxidation treatment method of 7 series aluminum alloy

An oxidation treatment, aluminum alloy technology, applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problem of uneven distribution, achieve the effect of reducing dissolution, strong adhesion, and uniform distribution of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

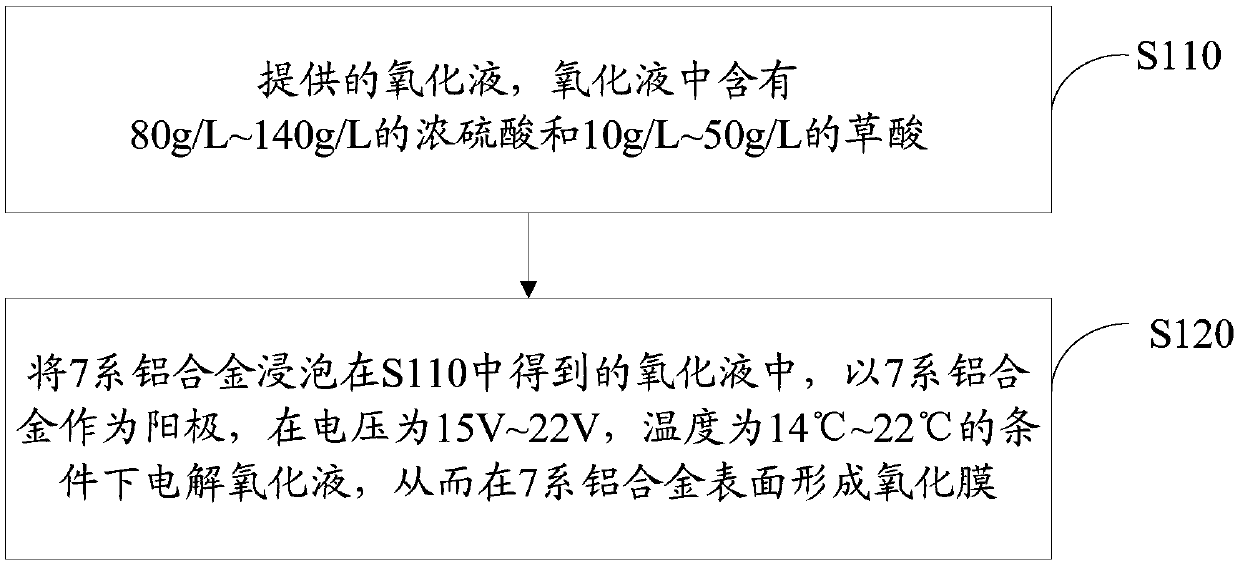

Method used

Image

Examples

Embodiment 1

[0043] Soak the 7-series aluminum alloy in the oxidation solution, which contains 120g / L concentrated sulfuric acid, 15g / L oxalic acid and the balance deionized water. The oxidation solution was electrolyzed for 60 minutes under the conditions of a constant voltage of 18V and a constant temperature of 15°C to form an oxide film on the surface of the 7 series aluminum alloy.

Embodiment 2

[0045] Soak the 7-series aluminum alloy in the oxidation solution, which contains 80g / L concentrated sulfuric acid, 10g / L oxalic acid and the balance deionized water. Under the conditions of a constant voltage of 15V and a constant temperature of 14°C, the oxidation solution was electrolyzed for 80 minutes to form an oxide film on the surface of the 7-series aluminum alloy.

Embodiment 3

[0047] Soak the 7-series aluminum alloy in the oxidation solution, which contains 140g / L concentrated sulfuric acid, 50g / L oxalic acid and the rest deionized water. Under the conditions of a constant voltage of 22V and a constant temperature of 22°C, the oxidation solution was electrolyzed for 40 minutes to form an oxide film on the surface of the 7-series aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com