Negative-pressure pre-stripping device and method for cathode zinc plate

A pre-stripping and cathode zinc technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of increased difficulty in peeling surface roughness, poor rigidity, easy deformation, low hardness and easy scratching, etc., and achieve high stripping efficiency and simple structure reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with accompanying drawing:

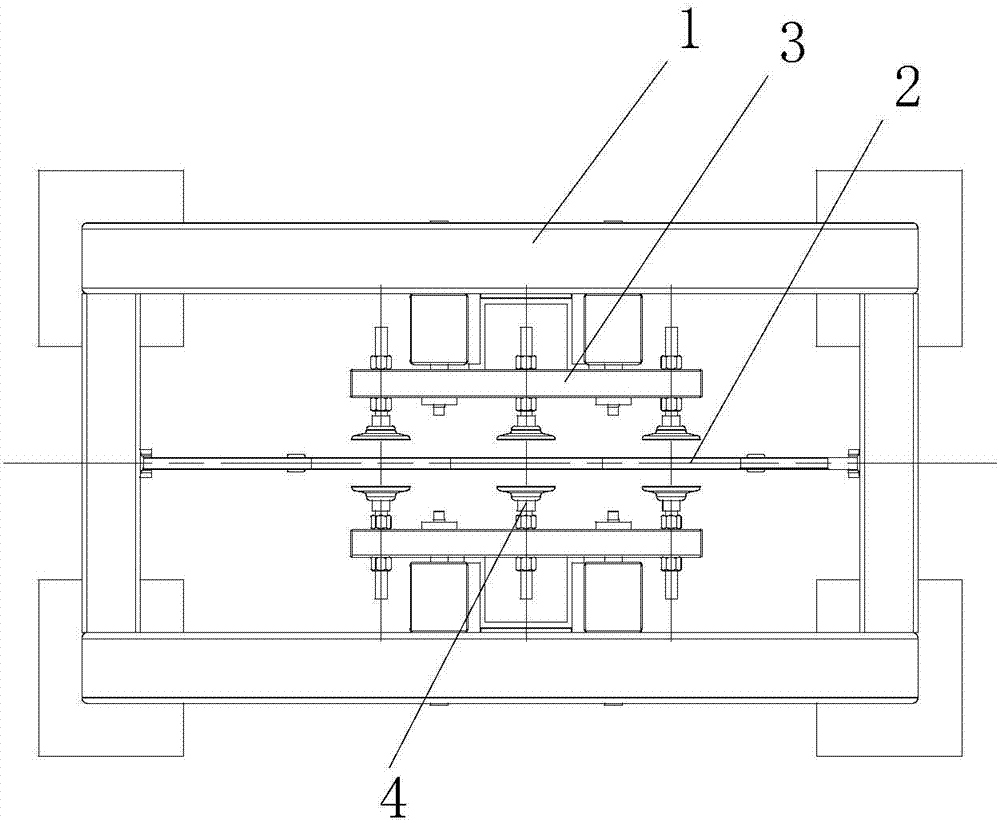

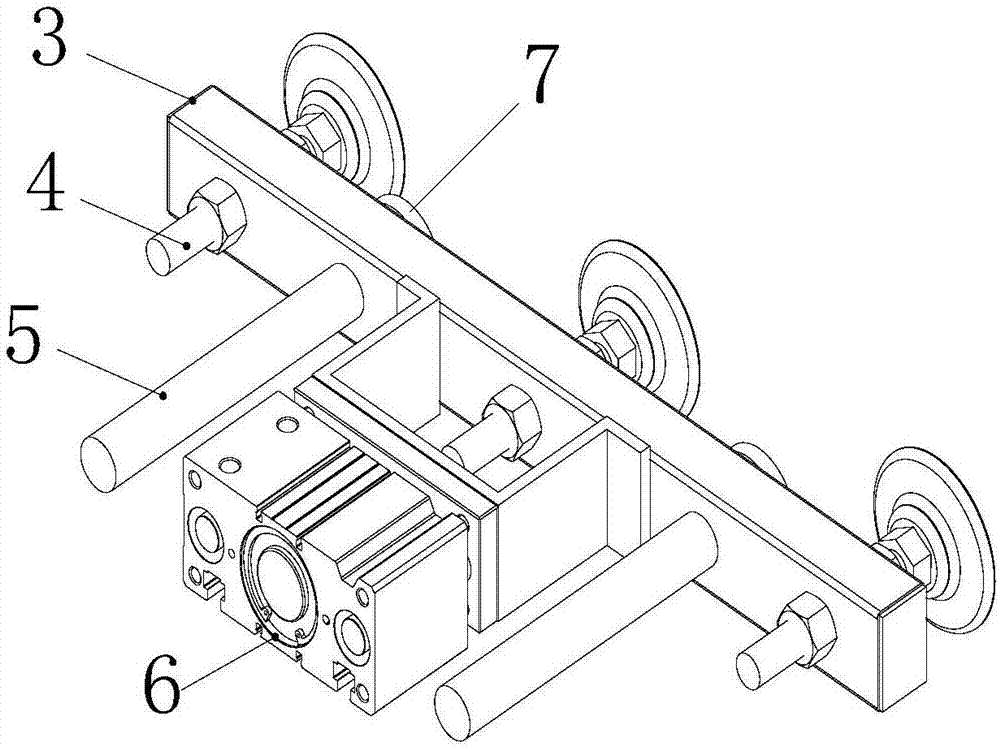

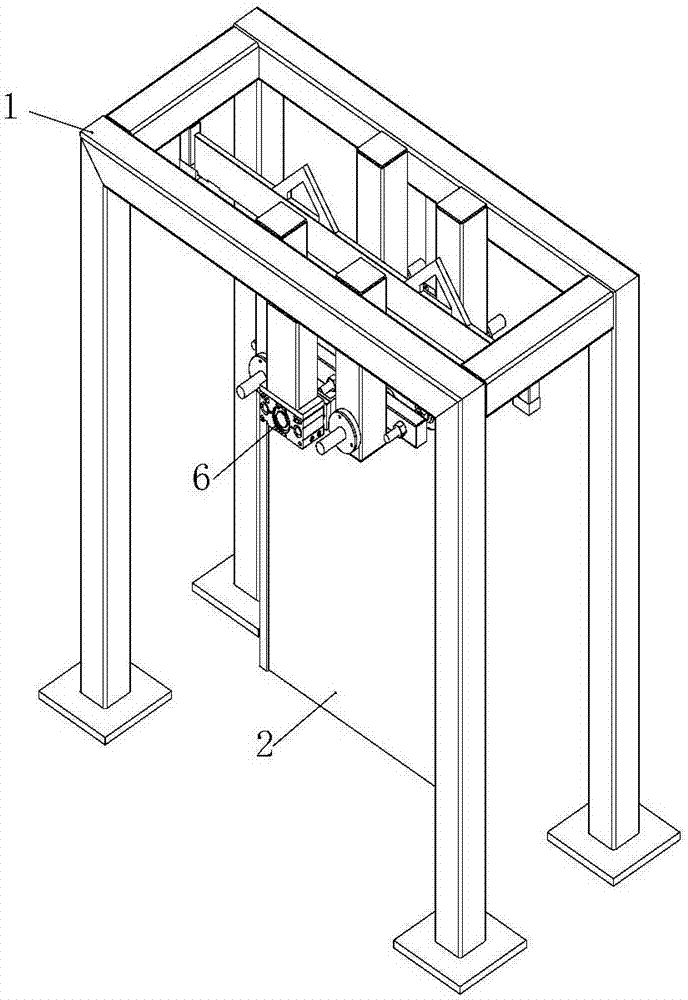

[0015] As shown in the figure, this cathode zinc plate negative pressure pre-stripping device mainly includes a frame 1, a guide rod 5 and a front and rear telescopic cylinder 6 are fixedly connected to the frame 1, and a vacuum suction cup holder 3 is slidably connected to the guide rod 5 , There are two groups of vacuum suction cups 4 on the vacuum suction cup holder 3, and the two groups of vacuum suction cups 4 are adsorbed on the front and back surfaces of the cathode plate 2 at the same time. The front and rear telescopic cylinders 6 are connected with the vacuum suction cup holder 3 and are used to drive the vacuum suction cup holder 3 to move back and forth along the guide rod 5 . At the end of the guide rod 5, an end cap 7 for positioning is arranged.

[0016] This cathode zinc plate negative pressure pre-stripping method controls the forward and backward moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com