Cathodic-disbonding knife device

A cathode stripping and stripping knife technology, which is applied in the electrolysis process, electrolysis components, etc., can solve the problems of occupying a relatively large processing space, unfavorable streamlining procedures, and residual metal plates, so as to achieve high stripping efficiency and improve the success rate of pre-stripping , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

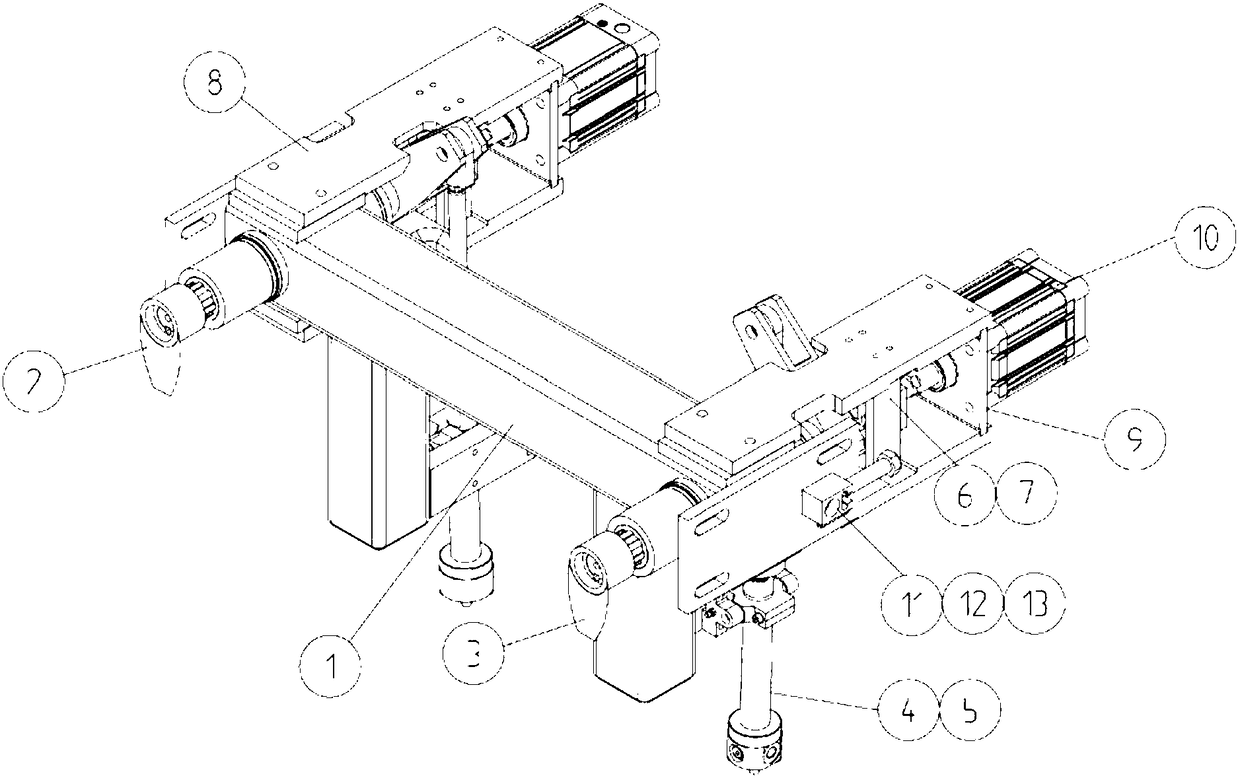

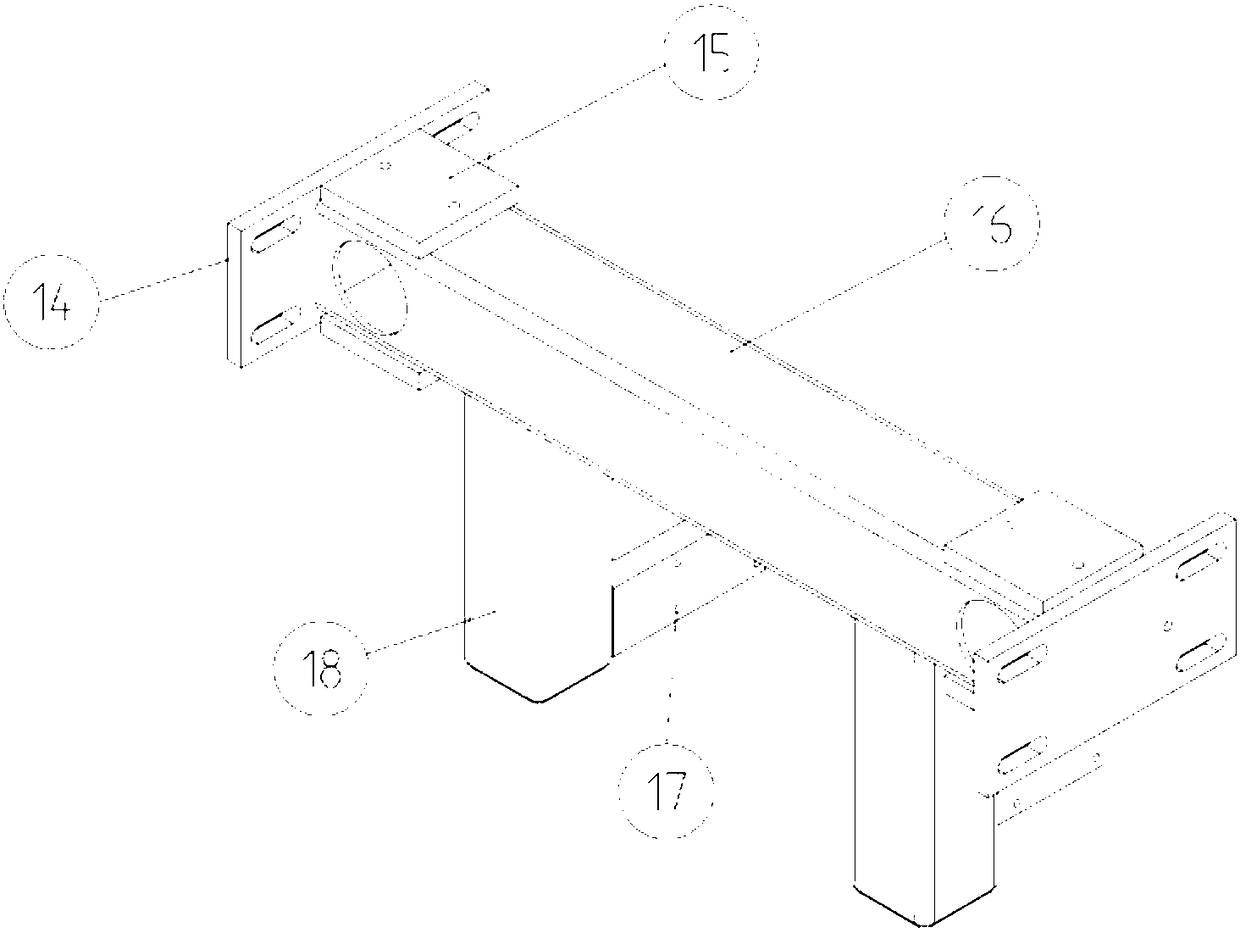

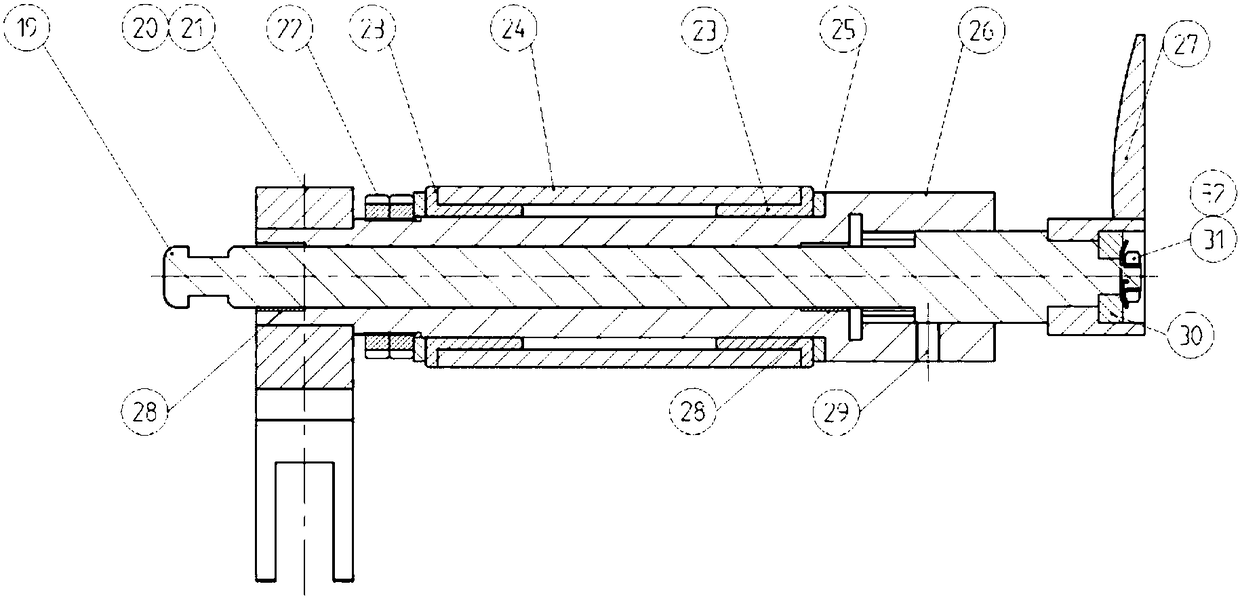

[0015] Embodiment: As shown in the drawings, this cathode stripping knife device mainly includes a stripping knife holder 1, a left stripping knife assembly 2, a right stripping knife assembly 3, a stripping knife rotary cylinder 5, a connecting plate 6, and a cylinder connecting block 7 , cylinder cover plate 8, cylinder mounting seat 9, stripping knife drive cylinder 10, left stripping knife assembly 2 and right stripping knife assembly 3 are installed symmetrically at both ends of stripping knife rest 1, and oil cylinder mounting seat 17 of stripping knife rest 1 is connected to the trunnion support Seat 4 and stripping knife rotary oil cylinder 5, left stripping knife assembly 2 and right stripping knife assembly 3 are connected with connecting plate one 6, cylinder connecting block 7, cylinder cover plate 8, and cylinder cover plate 8 tail end is connected cylinder mounting seat 9, cylinder The stripping knife driving cylinder 10 is installed on the mount 9, and the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com