Method for continuously fermenting to produce ethyl alcohol by using immobilized wine brewing yeast cells

A technology of Saccharomyces cerevisiae cells and yeast cells, which is applied in the field of industrial biological fermentation, can solve the problems of low efficiency and high cost, and achieve the effects of reducing production costs, improving fermentation performance, and facilitating automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example illustrates the effects of different treatment methods of pig small intestine as an immobilized carrier on ethanol fermentation. In order to explore the effect of different fermentation temperatures on ethanol production, pig small intestines with different treatments were used for ethanol fermentation. The results are as follows: figure 1 shown.

[0035] The pig small intestine was soaked in 75% ethanol for 30 minutes, soaked in 0.1M NaOH for 30 minutes, freeze-dried, autoclaved, etc., and added to the fermentation broth at a mass ratio of 8%. The condition of ethanol fermentation is anaerobic fermentation under the condition of 30° constant temperature and 200 rpm without gas, and the comparison chart of ethanol production by Saccharomyces cerevisiae fermentation under different treatment methods of pig small intestine is obtained, as shown in figure 1 shown. Concrete fermentation implementation steps are as above. Under the same fermentation time, the...

Embodiment 2

[0037] This example illustrates the effects of different addition amounts of porcine small intestine as an immobilized carrier on ethanol fermentation.

[0038] Add pig small intestine carriers treated with 75% ethanol to the fermentation broth at a mass ratio of 40:1000, 80:1000, and 120:1000 respectively. The specific fermentation implementation steps are as above, and the results are as follows figure 2 shown. According to specific fermentation implementation steps as above. According to the fermentation results, within the ratio range of the examples, the experimental effects of the other two groups are not as good as the 80:1000 pig small intestine carrier addition. It can be seen that the addition of 80:1000 is optimal in this invention.

Embodiment 3

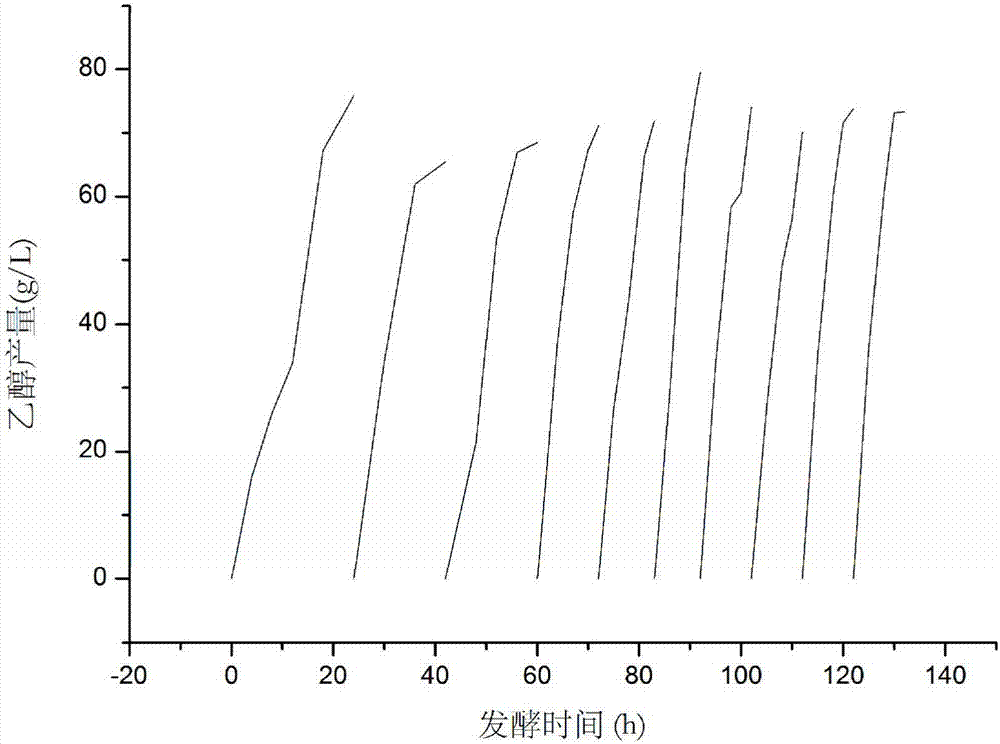

[0040] This example illustrates the effect of porcine small intestine as an immobilized carrier of Saccharomyces cerevisiae during continuous fermentation.

[0041] The pig small intestine immobilized carrier treated with 75% ethanol was added to the fermentation broth at a mass ratio of 80:1000. When the glucose content in the fermentation broth was below 10g / L, the fresh fermentation broth was replaced, and 10 batches of continuous fermentation were carried out. Fermentation results such as image 3 . According to the fermentation data, it can be seen that with the increase of fermentation batches, the fermentation time is correspondingly shortened, and the fermentation rate is gradually accelerated. After the fourth batch of fermentation, the fermentation yield is basically maintained at 5.8-7.2gL -1 h -1 , compared to 1-3gL of ethanol produced by fermentation with free yeast cells -1 h -1 , production efficiency is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com