Method for producing needle-shaped coke raw material by delayed coking process

A needle coke raw material and delayed coking technology, which is applied in the coking of carbonaceous materials, coke ovens, petroleum industry, etc., can solve the problems of high cost and large investment, and achieve the effects of low cost, expanded sources and easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

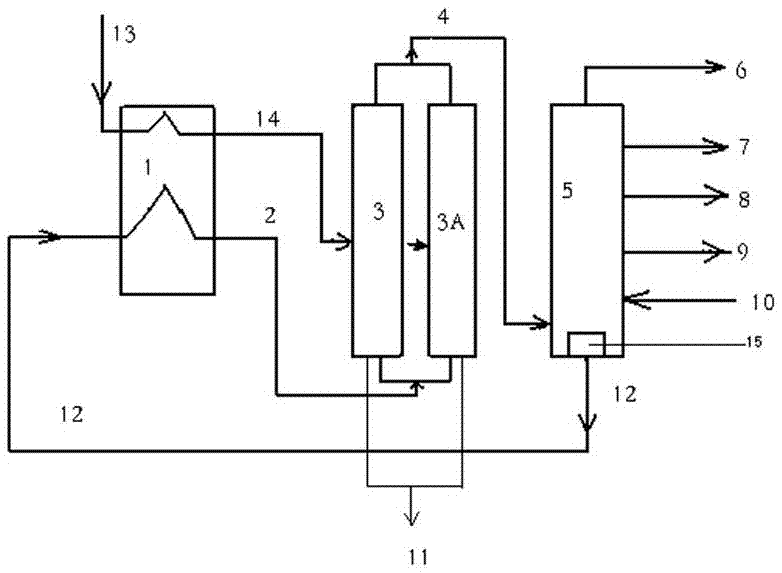

[0033] The following combination figure 1 and specific examples are explained in further detail, but the present invention is not limited by the examples.

[0034] like figure 1 Shown, a kind of method utilizing delayed coking technology to produce needle coke raw material, comprises the steps:

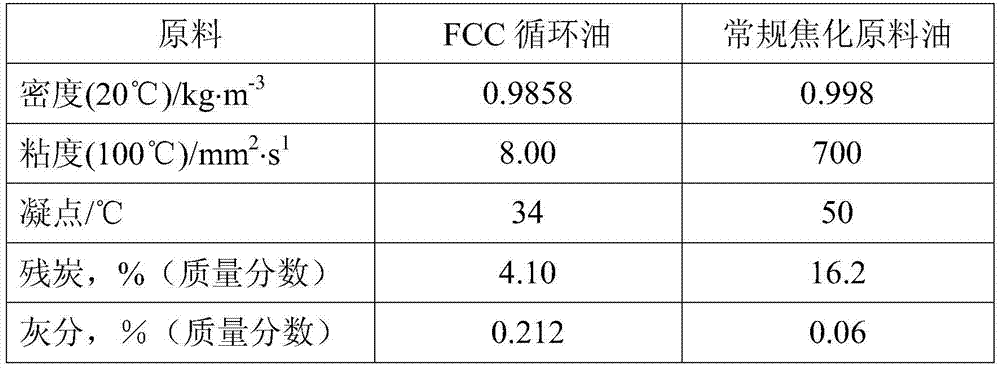

[0035](1) The conventional coking raw material is heated to 540°C by the heating furnace, and the furnace outlet temperature is controlled to 485°C, and enters the delayed coking tower from the bottom of the delayed coking tower; the FCC circulating oil enters the heating furnace through the coking raw material oil pipeline 12 from the bottom of the fractionating tower 1. After heating to 420°C, it enters the feed line 14 at the upper part of the coking tower, and enters the delayed coking tower 3 from the middle and upper part of the delayed coking tower 3; it contacts with the high-temperature oil and gas generated by the reaction of conventional coking raw materials entering from ...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] (1) The conventional coking raw material is heated to 550°C by the heating furnace, and the furnace outlet temperature is controlled at 500°C, and enters the delayed coking tower from the bottom of the delayed coking tower; the FCC circulating oil enters the heating furnace through the coking raw material oil pipeline 12 from the bottom of the fractionating tower 1. Heating to 400°C, entering the feed line 14 at the upper part of the coking tower, and entering the delayed coking tower 3 from the middle and upper part of the delayed coking tower 3;

[0050] The initial boiling point of the needle coke raw material is 380°C, and the final boiling point is 460°C.

[0051] The outlet temperature of the FCC circulating oil heating furnace is 100°C lower than the outlet temperature of the conventional coking raw material heating furnace.

[0052] The feed weight ratio of the FCC cycle oil to conventional co...

Embodiment 3

[0054] The difference between this embodiment and embodiment 1 is:

[0055] (1) The conventional coking raw material is heated to 545°C by the heating furnace, and the furnace outlet temperature is controlled to 495°C, and enters the delayed coking tower from the bottom of the delayed coking tower; the FCC circulating oil enters the heating furnace through the coking raw material oil pipeline 12 from the bottom of the fractionating tower 1. After heating to 410°C, enter the delayed coking tower 3 from the middle and upper part of the delayed coking tower 3 through the feed line 14 at the upper part of the coking tower;

[0056] The initial boiling point of the needle coke raw material is 360°C, and the final boiling point is 450°C.

[0057] The feed weight ratio of the FCC cycle oil to conventional coking raw materials is 50:50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com