Sealing strip coating rubber and preparation method thereof, and car door sealing strip and preparation method thereof

A technology for covering rubber and sealing strips, which is applied to the preparation of door sealing strips and the door sealing strips, sealing strips covering rubber, and preparing the sealing strips covering rubber fields, which can solve the problem of not meeting the needs of customers and the cost of sealing strips Problems such as pressure and slag drop, achieve good mixing and extrusion processing performance, improve appearance performance, and excellent heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

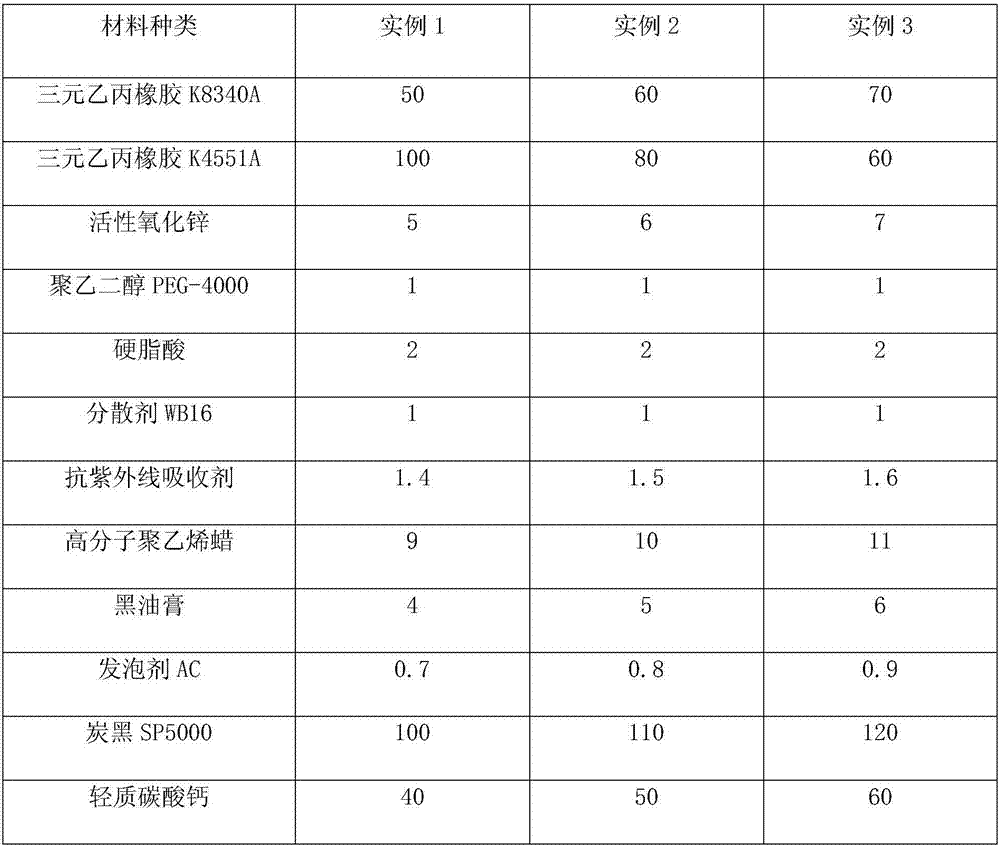

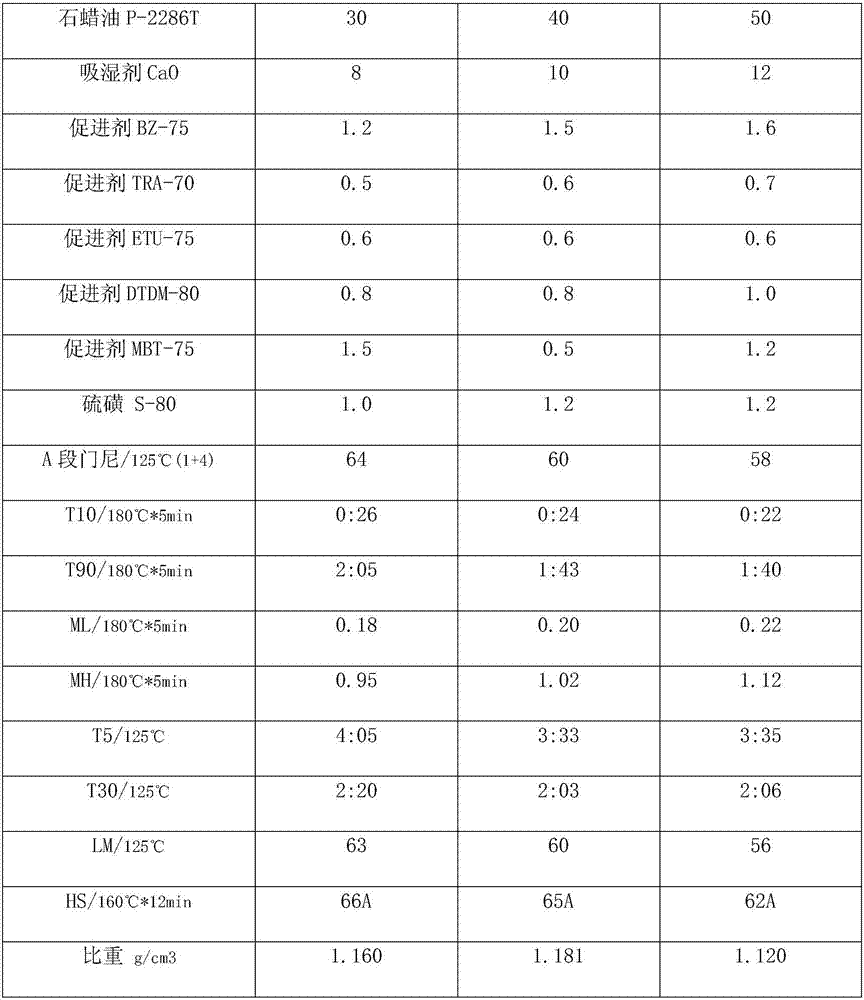

[0052] This embodiment relates to a sealing strip coated rubber, which is specifically made of the following components by weight: EPDM K8340A: 50-70 parts, EPDM K4551A: 60-100 parts, oxidized Zinc: 5-7 parts, polyethylene glycol PEG-4000: 1 part, stearic acid: 2 parts, dispersant WB16: 1 part, anti-ultraviolet absorber: 1.4-1.6 parts, high molecular polyethylene wax: 9- 11 parts, black ointment: 4-6 parts, foaming agent AC: 0.7-09 parts, carbon black SP5000: 90-130 parts, light calcium carbonate: 40-6 parts, paraffin oil P-2286T: 30-50 parts Parts, moisture absorbent CaO: 8-12 parts, accelerator: 5-7 parts, sulfur: 1.0-1.4 parts.

[0053] Among them, the accelerator specifically includes the following components by weight: accelerator BZ-75: 1.25-1.75 parts, accelerator TRA-70: 0.5-0.9 parts, accelerator ETU-75: 0.4-0.8 parts, accelerator DTDM -80: 0.6-1.0 parts, Accelerator MBT-75: 1.3-1.7 parts.

[0054] The preparation process of the sealing strip coated rubber of the pr...

Embodiment 2

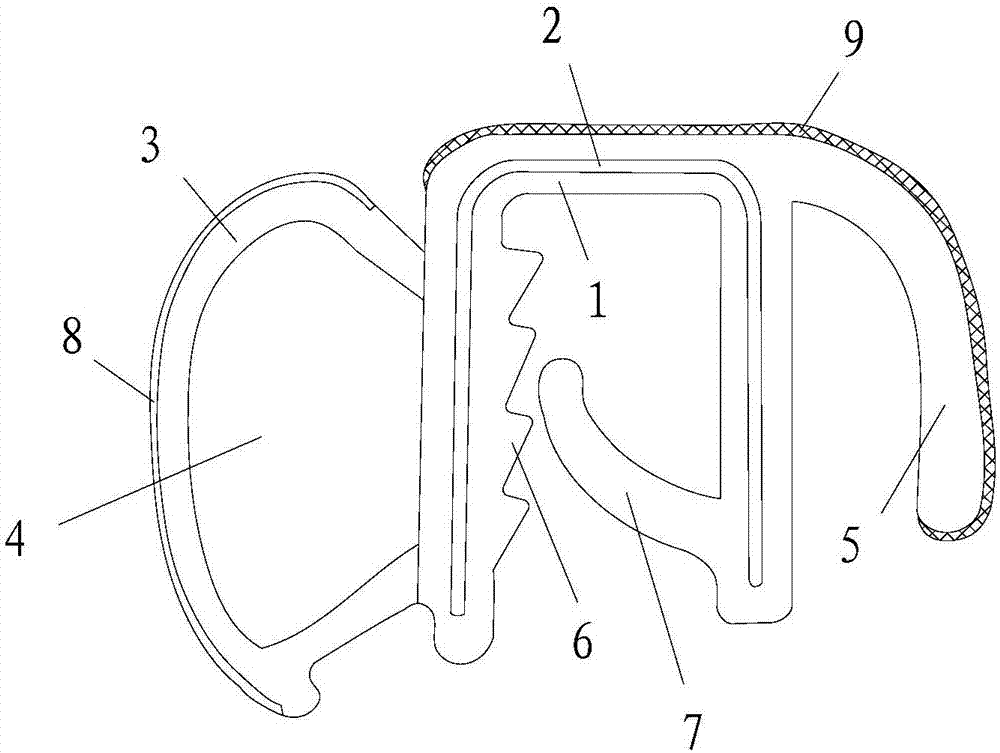

[0064] This embodiment relates to a kind of door sealing strip, such as figure 1 As shown in , it includes a mounting part 1 made of dense rubber with a built-in steel belt 2. The mounting part 1 is in an inverted "U" shape, and a seal made of sponge rubber is connected to one side of the mounting part 1. part 3 , and a cavity 4 is formed between the sealing part 3 and the installation part 1 , the cavity 4 can improve the sealing effect of the sealing part 3 . Relative to the sealing portion 3 , a lip 5 extending to the other side of the mounting portion 3 is provided on the top of the mounting portion 1 . A flocking layer 9 is provided on the outer surface of the lip 5 , and the outer surface of the sealing part 3 is coated with a coating layer 8 formed of the sealing strip coating rubber described in the first embodiment.

[0065] In this embodiment, in order to improve the clamping strength of the mounting part 1 on the car door, a plurality of tooth-shaped parts 6 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com