Preparation method of coating film with reinforced antifogging function

An anti-fog film and coating film technology, which is applied in the field of self-adhesive, can solve the problems of leaf diseases and insect pests and rot, and affect the light transmittance of agricultural films, etc., to improve heat aging resistance, significant anti-fog effect, and suppress diseases The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

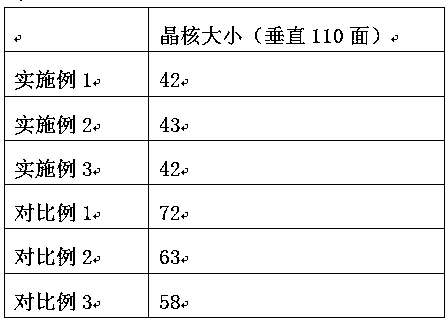

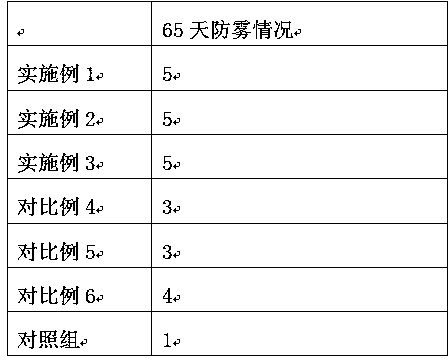

Examples

Embodiment 1

[0023] A method for preparing a coated enhanced anti-fog film. A layer of coating film is coated on the surface of a modified PET film, and the modified PET film is made of the following components in parts by weight: PET resin 95, castor oil modified Nano-bentonite 15, plasticizer 1.2; the coating film is formed by drying the coating solution on the surface of the modified PET film, and the coating solution is made of the following components in parts by weight: 3-glycidoxypropoxypropyl Triethoxysilane 4, propylene glycol 15, camellia seed oil 2, sodium dodecylbenzene sulfonate 5, castor oil modified nano-bentonite 5, deionized water 50.

[0024] Further, the preparation method of castor oil modified nano-bentonite comprises the following steps:

[0025] (1) Add the peptide nucleic acid into the buffer, stir at 120r / min for 30min at 40°C, then add nano-bentonite particles with 15% buffer mass, and stir at 200r / min at a constant temperature of 55°C After 2 hours, add formamid...

Embodiment 2

[0040] A method for preparing a coated enhanced anti-fog film. A layer of coating film is coated on the surface of a modified PET film, and the modified PET film is made of the following components in parts by weight: PET resin 98, castor oil modified Nano-bentonite 20, plasticizer 1.6; the coating film is formed by drying the coating solution on the surface of the modified PET film, and the coating solution is made of the following components in parts by weight: 3-glycidoxypropoxypropyl Triethoxysilane 6, propylene glycol 18, camellia seed oil 3, sodium dodecylbenzene sulfonate 7, castor oil modified nano-bentonite 8, deionized water 55.

[0041] Further, the preparation method of castor oil modified nano-bentonite comprises the following steps:

[0042] (1) Add the peptide nucleic acid into the buffer, stir at 120r / min for 30min at 40°C, then add nano-bentonite particles with 15% buffer mass, and stir at 200r / min at a constant temperature of 55°C After 2 hours, add formamid...

Embodiment 3

[0057] A method for preparing a coated enhanced anti-fog film. A layer of coating film is coated on the surface of a modified PET film, and the modified PET film is made of the following components in parts by weight: PET resin 96, castor oil modified Nano-bentonite 18, plasticizer 1.3; the coating film is formed by drying the coating solution on the surface of the modified PET film, and the coating solution is made of the following components in parts by weight: 3-glycidoxypropyl Triethoxysilane 5, propylene glycol 16, camellia seed oil 2.5, sodium dodecylbenzene sulfonate 6, castor oil modified nano-bentonite 7, deionized water 52.

[0058] Further, the preparation method of castor oil modified nano-bentonite comprises the following steps:

[0059] (1) Add the peptide nucleic acid into the buffer, stir at 120r / min for 30min at 40°C, then add nano-bentonite particles with 15% buffer mass, and stir at 200r / min at a constant temperature of 55°C After 2 hours, add formamide wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com