Method for curing non water-based ceramic suspensoid by inducing dispersing agent to neutralize at low temperature and ceramic forming method

A molding method and low-temperature induced technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of using non-aqueous ceramic suspensions without dispersants, and achieve the effects of high mechanical properties, good dispersion, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

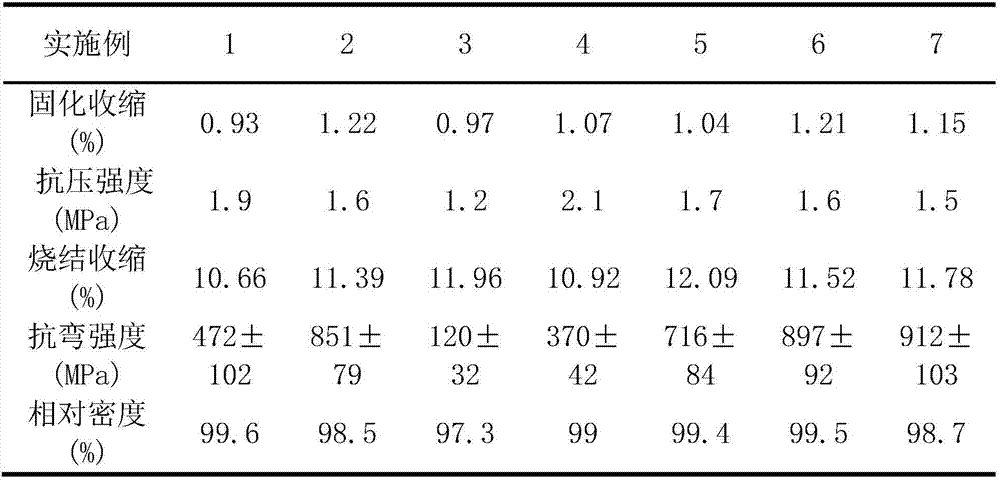

Examples

Embodiment 1

[0034] Alumina ceramic suspension was prepared and solidified with n-octane as solvent and oleic acid as dispersant.

[0035] 220 grams of alumina powder, 3.3 grams of oleic acid and 31.5 grams of n-octane were mixed and ball milled for 36 hours to prepare a ceramic suspension with a solid phase volume fraction of 55%. The suspension was injected into a non-porous glass mold, treated at a low temperature of -15°C for 48 hours, then demolded, dried in a vacuum environment for 20 minutes, and sintered at 1550°C for 2 hours to obtain a ceramic sintered body.

Embodiment 2

[0037] Using ethanol as solvent and nonanoic acid as dispersant to prepare and solidify zirconia ceramic suspension.

[0038] 290 grams of zirconia powder, 1.5 grams of nonanoic acid and 39.45 grams of ethanol were mixed and ball milled for 24 hours to prepare a ceramic suspension with a solid phase volume fraction of 50%. The suspension was injected into a non-porous metal mold, treated at a low temperature of -20°C for 24 hours, then demolded, dried in a vacuum environment for 10 minutes, and sintered at 1500°C for 3 hours to obtain a ceramic sintered body.

Embodiment 3

[0040] Using n-heptane as solvent and nonanoic acid as dispersant to prepare and cure silica ceramic suspension.

[0041] Mix 132.5 grams of silicon oxide powder, 3.2 grams of nonanoic acid and 34 grams of n-heptane, and ball mill for 12 hours to prepare a ceramic suspension with a solid phase volume fraction of 50%. The suspension was injected into a non-porous plastic mold, treated at a low temperature of -20°C for 24 hours, then demolded, dried in a vacuum environment for 15 minutes, and sintered at 1270°C for 3 hours to obtain a ceramic sintered body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com