System and method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste

A technology of sulphoaluminate cement and organic wastewater, applied in cement production, clinker production, etc., can solve problems such as personal health threats and environmental pollution, and achieve the effects of energy utilization, production cost reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

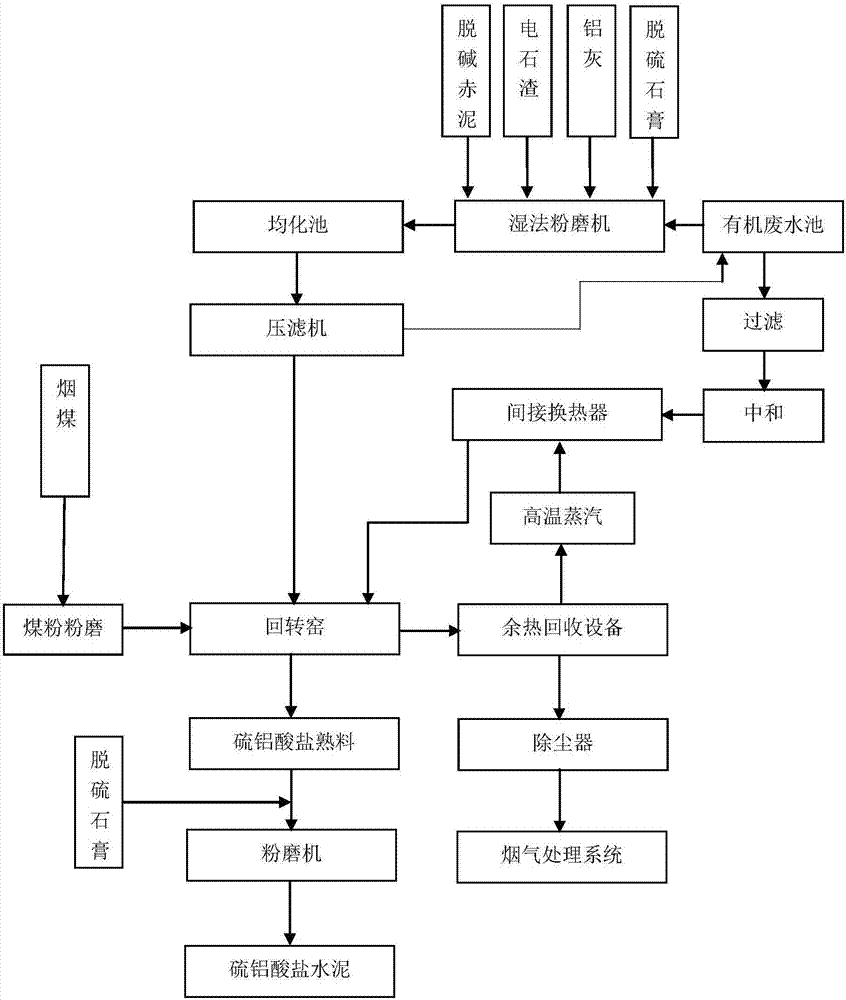

Image

Examples

Embodiment 1

[0089] According to the above-mentioned system and the above-mentioned process, the specific parameters, calculation results and detection are as follows: based on the mass of the solid-liquid mixture after mixing and matching, dealkalized red mud accounts for 35.45%, calcium carbide slag accounts for 24.61%, and aluminum ash accounts for 18.32% %, desulfurized gypsum accounted for 21.62%, based on the mass of calcined raw meal: SiO 2 8.14%, Al 2 o 3 Accounting for 31.20%, Fe 2 o 3 3.72%, CaO 43.23%, MgO 0.33%, TiO 2 1.30%, SO 3 Accounted for 8.94%. Coal powder accounted for 2.53%. Concentrated organic waste water is added to the raw meal and sent to the rotary kiln for calcination at a temperature of 1280°C. Calcination time was 60 minutes. At this time, dioxins, furans, PCBs, etc. can be eliminated very well. Then the flue gas passes through the waste heat recovery equipment to recover the heat. Finally, dust removal and flue gas treatment are carried out on the fl...

Embodiment 2

[0091] According to the above-mentioned system and the above-mentioned process, the specific parameters, calculation results and detection are as follows: based on the mass of the solid-liquid mixture after mixing and matching, dealkalized red mud accounts for 46.86%, calcium carbide slag accounts for 25.34%, and aluminum ash accounts for 10.45%. %, desulfurized gypsum accounted for 17.35%. Concentrated organic waste water is added to the raw meal and sent to a rotary kiln for calcination. The calcination temperature is 1290°C and the calcination time is 60 minutes. No harmful substances such as dioxins, furans, and PCBs were found in the treated flue gas. According to the cement mortar strength test method, the 3-day and 28-day compressive strengths are 40.8MPa and 43.7MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com