A centrifugal casting device

A centrifugal casting and mold technology, applied in the field of centrifugal casting devices, can solve the problems that the casting mold is difficult to cool uniformly, the castings are not easily separated, and the defective rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The rainwater treatment device with improved structure according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

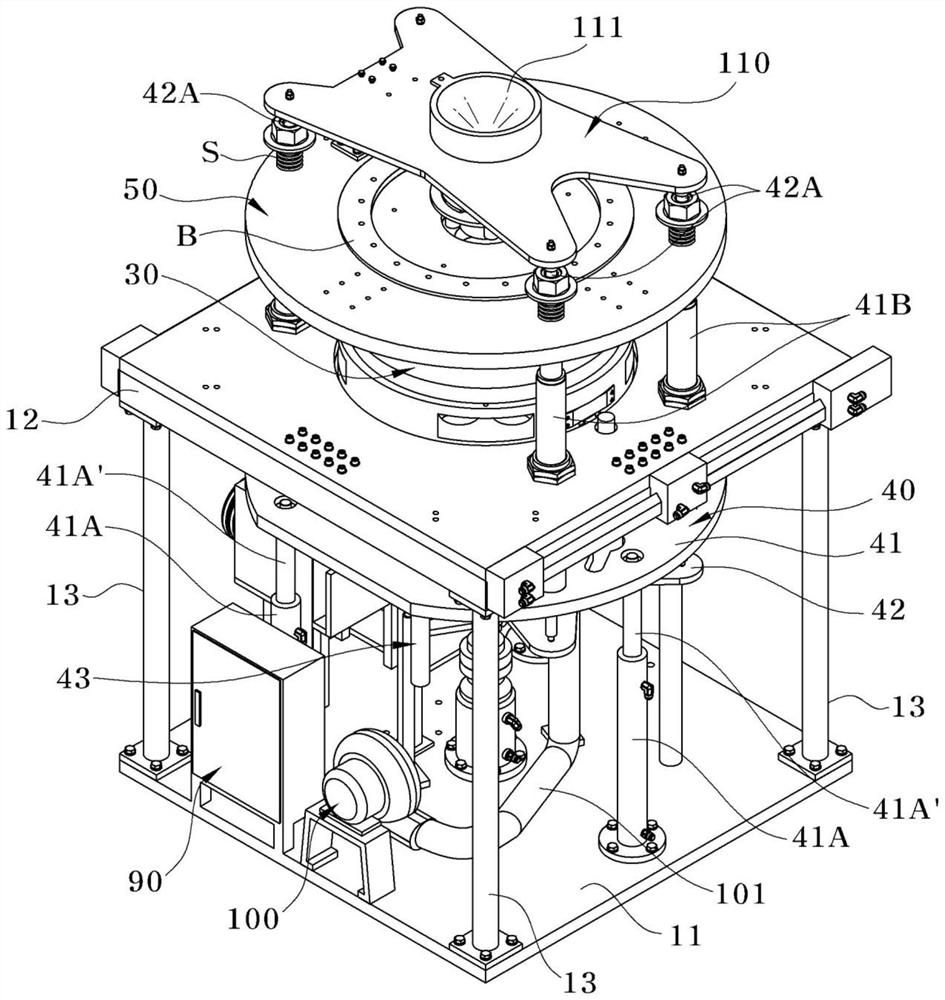

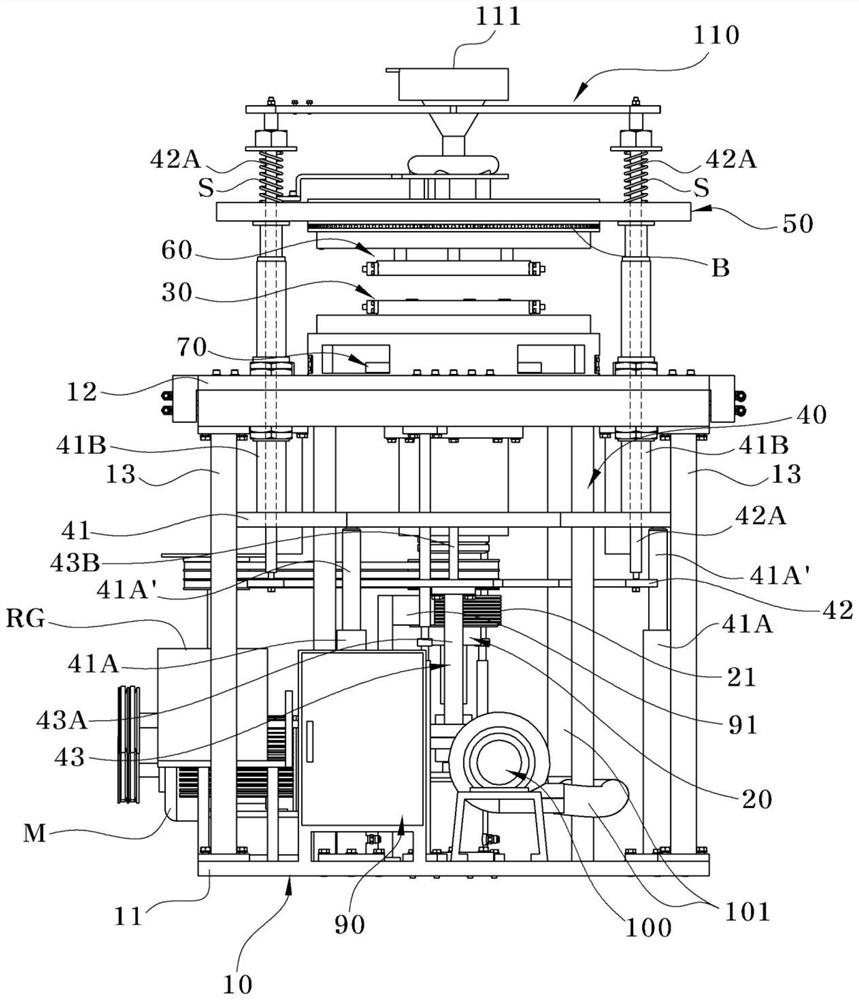

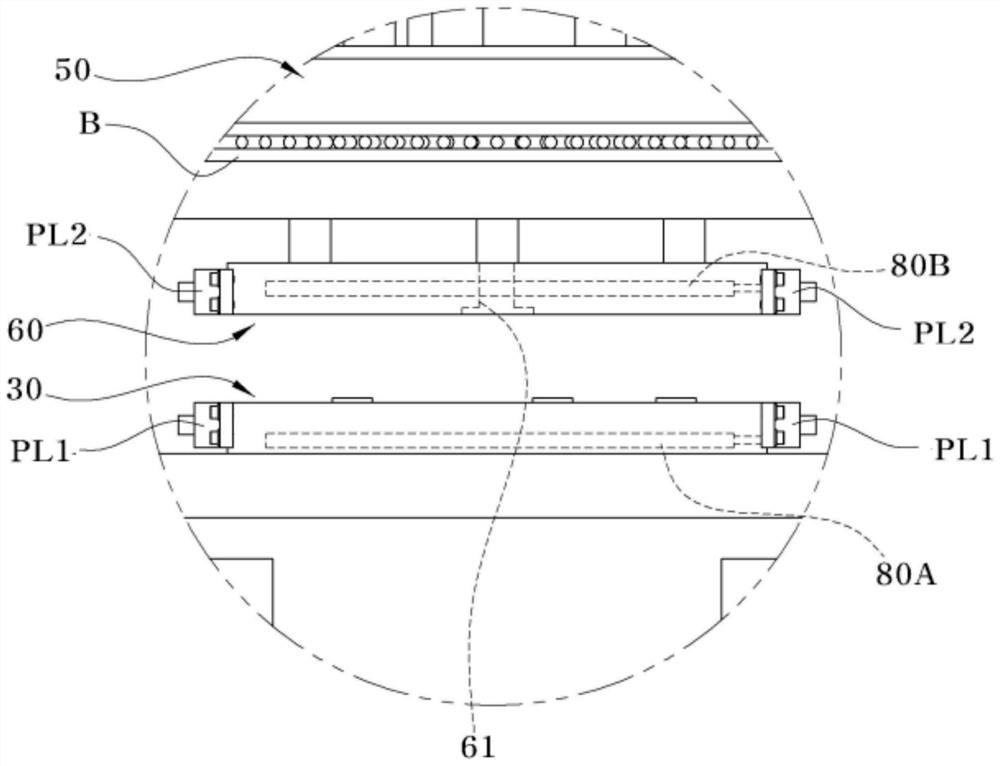

[0060] The invention relates to a centrifugal casting device. The upper and lower molds of the centrifugal casting device can be strongly attached to each other and rotate together. The upper and lower molds are heated at a high temperature so that the melt is not easy to cool, but can be cooled rapidly when needed. Such as figure 1 and figure 2 Shown, centrifugal casting device of the present invention comprises:

[0061] Main frame 10, which is a frame structure with open front, rear, left, and right sides;

[0062] The main shaft 20 is installed in the center of the main frame 10 and passes through the main frame 10, and is rotated by means of the motor M;

[0063] The lower mold 30 is installed on the main frame 10 and rotates by means of the main shaft 20;

[0064] The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com