Control method and system for automatically compensating pipe end liquid leakage in internal high pressure forming

A technology of internal high-pressure forming and automatic compensation, which is applied in the field of pipe forming processing, can solve the problems of leak detection, leakage, and pressure detection methods that cannot be used, and achieve the effect of improving the yield and restoring the seal of the pipe end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

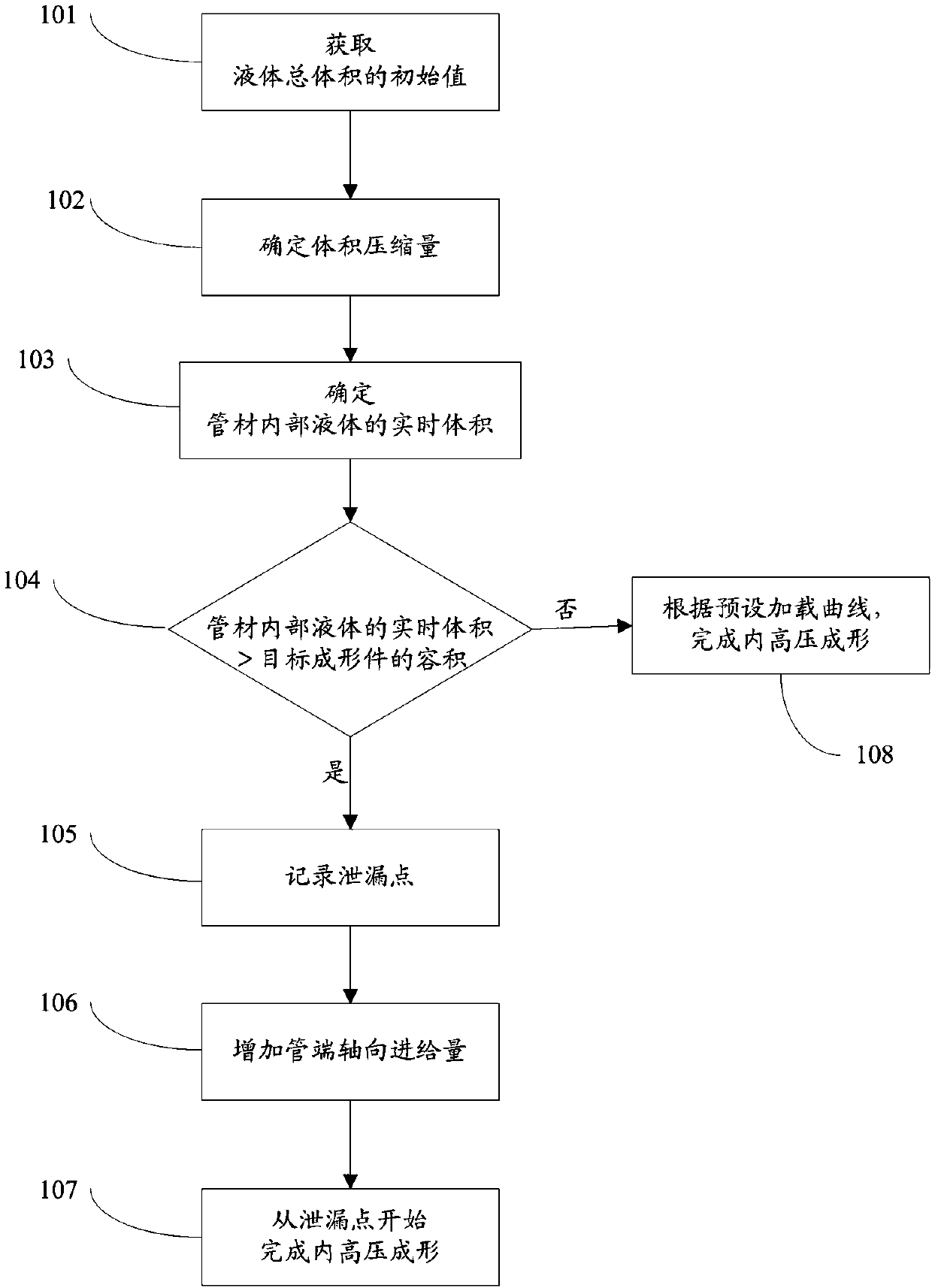

[0070] like figure 1 As shown, the control method for automatically compensating for liquid leakage at the pipe end in internal high pressure forming includes the following steps:

[0071] Step 101: Obtain the initial value of the total volume of the liquid in the high-pressure chamber of the supercharger, the liquid inside the pipe, and the liquid inside the high-pressure pipeline at the start of the internal high-pressure forming;

[0072] Step 102: Determine the volume compression of the total volume according to the initial value of the total volume and the real-time pressure of the liquid inside the pipe;

[0073] Step 103: Determine the real-time volume of the liquid inside the pipe according to the volume compression, the initial value of the total volume, the real-time volume of the liquid in the high-pressure chamber under the real-time pressure, and the real-time volume of the liquid inside the high-pressure pipeline; wherein, the real-time volume of the liquid in th...

Embodiment 2

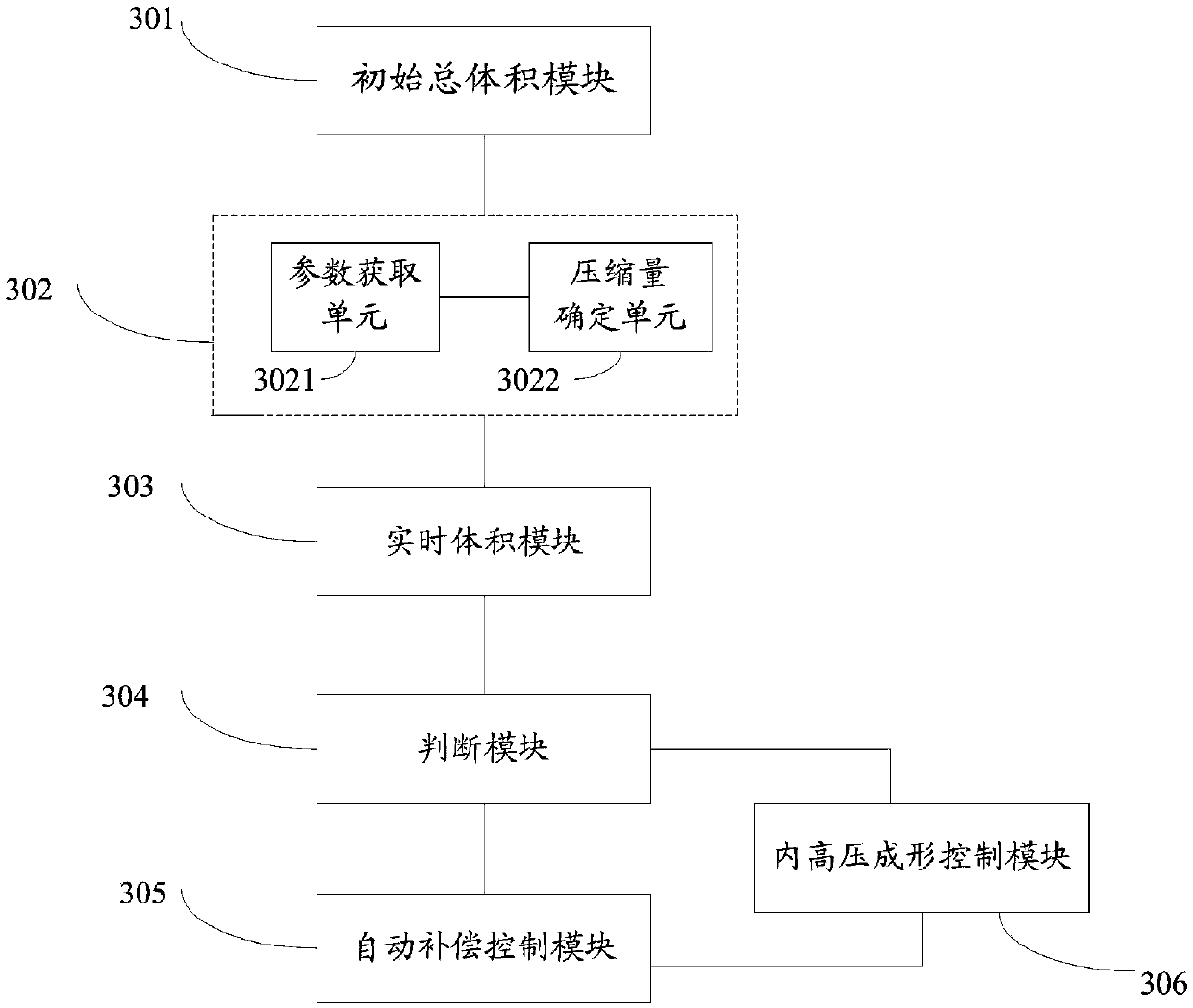

[0090] Such as image 3 As shown, the control system for automatically compensating the liquid leakage at the pipe end in internal high pressure forming includes:

[0091] The initial total volume module 301 is used to obtain the initial value of the total volume of the liquid in the high-pressure chamber of the supercharger, the liquid inside the pipe, and the liquid inside the high-pressure pipeline at the beginning of the internal high pressure forming;

[0092] A volume compression module 302, configured to determine the volume compression of the total volume according to the initial value of the total volume and the real-time pressure of the liquid inside the pipe;

[0093] A real-time volume module 303, configured to use the volume compression amount, the initial value of the total volume, the real-time volume of the liquid in the high-pressure chamber under the real-time pressure, and the real-time volume of the liquid inside the high-pressure pipeline determining the ...

Embodiment 3

[0102] Such as Figure 4 As shown, the controller 10 for automatically compensating the liquid leakage at the pipe end in the internal high pressure forming is used to control the internal high pressure forming machine 401. The controller 10 includes: an initial total volume module, a volume compression module, a real-time volume module, a judgment module, and an automatic compensation Control module and internal high pressure forming control module.

[0103] Such as Figure 4 As shown, the left punch 5 is installed on the left servo cylinder 6, the left servo cylinder 6 is installed with a built-in first displacement sensor 7, the left servo cylinder 6 is controlled by the first proportional servo valve 8, and the right punch 2 is installed on the right servo cylinder 22, the right servo cylinder 22 is equipped with a built-in second displacement sensor 21, and the right servo cylinder 22 is controlled by the second proportional servo valve 12.

[0104] The principle of sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com