Post-treatment method of phenol hydrogenation Pd@CN catalyst

A catalyst and phenol technology, applied in the field of catalysis, can solve the problems of deactivation, no Pd@CN catalyst regeneration and post-treatment methods, and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The reacted mixture was filtered through filter paper to separate the Pd@CN catalyst and solution. Put 6.4g of the recovered Pd@CN catalyst into a 1000mL beaker, add 500mL of deionized water, and stir at 70°C for 30min at a stirring rate of 400r / min. Filtrate while it is hot, the filtration temperature is controlled at 60°C, and the washed Pd@CN catalyst is recovered. Repeat the above washing steps three times. The Pd@CN catalyst washed three times was soaked in 200 mL deionized water.

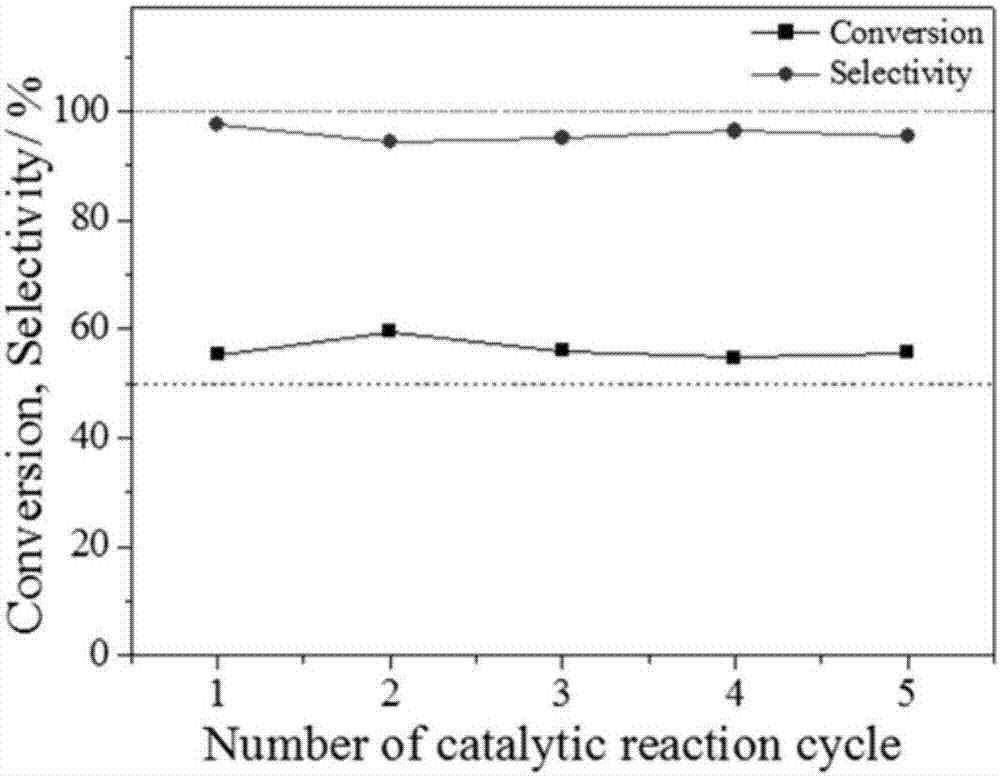

[0026] The Pd@CN catalyst washed three times was added to the reactor together with 200mL deionized water, and used in the experiment of hydrogenation of phenol to cyclohexanone. The reaction was stopped after 2 hours, and it was recycled 5 times under the subsequent treatment method. The results are as follows figure 2 shown. The Pd@CN catalyst maintained good catalytic activity and selectivity in 5 sets of tests.

Embodiment 2

[0028] The reacted mixture was filtered through filter paper to separate the Pd@CN catalyst and solution. Put 6.4g of the recovered Pd@CN catalyst into a 200mL beaker, add 128mL of deionized water, and stir at 60°C for 10min at a stirring rate of 100r / min. Filtrate while it is hot, the filtration temperature is controlled at 50°C, and the washed Pd@CN catalyst is recovered. Repeat the above washing step twice. The Pd@CN catalyst washed twice was soaked in 64 mL deionized water.

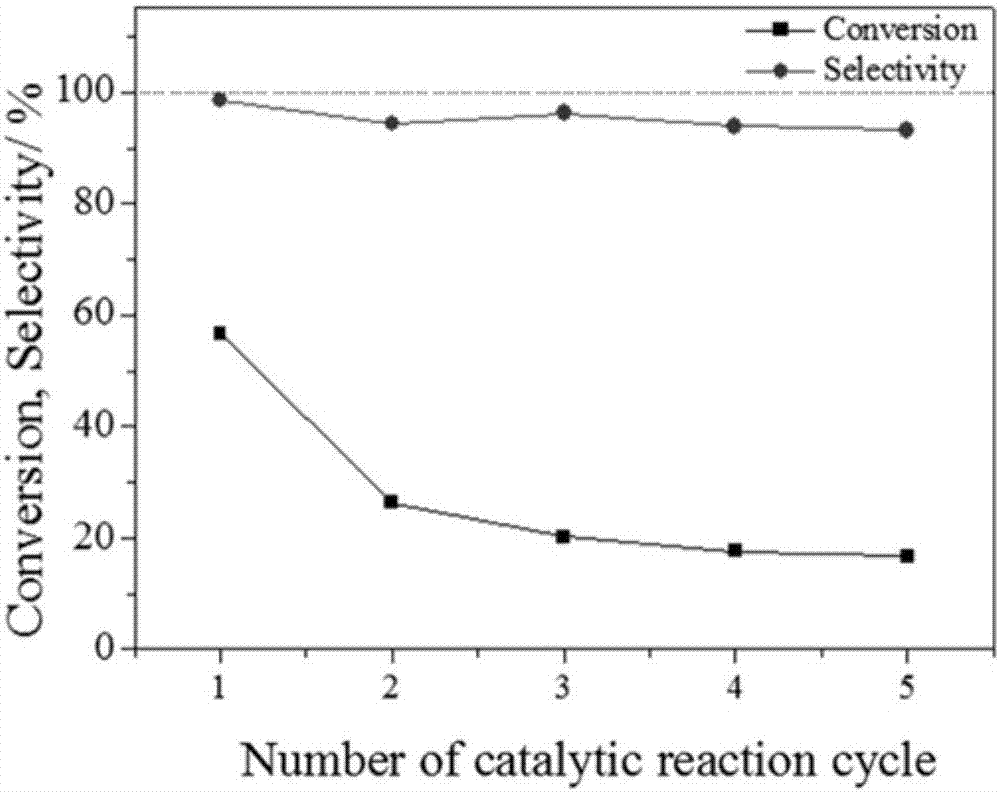

[0029] The Pd@CN catalyst washed twice was added to the reactor together with 64 mL of deionized water for the experiment of hydrogenation of phenol to cyclohexanone, and the reaction was stopped after 2 hours. Through 5 repeated experiments, the catalytic activity decreased by 8.2%.

Embodiment 3

[0031] The reacted mixture was filtered through filter paper to separate the Pd@CN catalyst and solution. Put 6.4g of the recovered Pd@CN catalyst into a 2000mL beaker, add 950mL of deionized water, and stir at 90°C for 1h at a stirring rate of 500r / min. Filtrate while it is hot, the filtration temperature is controlled at 90°C, and the washed Pd@CN catalyst is recovered. Repeat the above washing steps five times. The Pd@CN catalyst washed five times was soaked in 640 mL deionized water.

[0032] The Pd@CN catalyst washed five times was added to the reactor together with 640 mL of deionized water for the experiment of hydrogenation of phenol to cyclohexanone, and the reaction was stopped after 2 hours. Through 5 repeated experiments, the catalytic activity decreased by 3.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com