Sharing and resource utilization system and method of high-calcium fly ash for multi-unit plant

A high-calcium fly ash and multi-unit technology, applied in the field of high-calcium fly ash sharing and resource utilization systems, can solve problems such as waste, unused CaO, and difficult comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

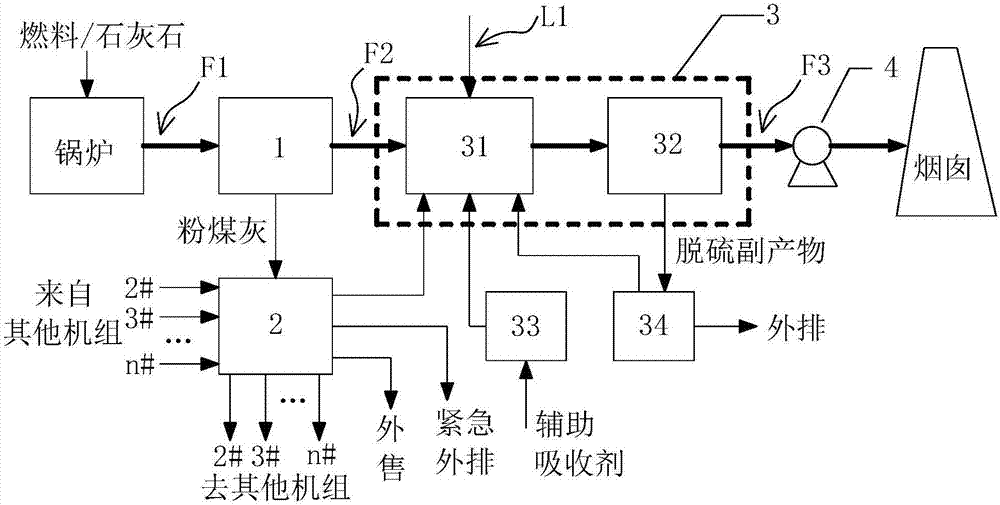

[0068] High-calcium fly ash sharing and resource utilization system for multi-unit power station

[0069] This embodiment provides a kind of figure 1 The high-calcium fly ash sharing and resource utilization system of the multi-unit power station shown includes circulating fluidized bed boilers arranged in sequence along the flue gas flow direction, pre-dust collector 1, high-calcium fly ash distribution system 2, circulation Fluidized bed dry desulfurization absorption tower 31, post dust collector 32, induced draft fan 4 and chimney.

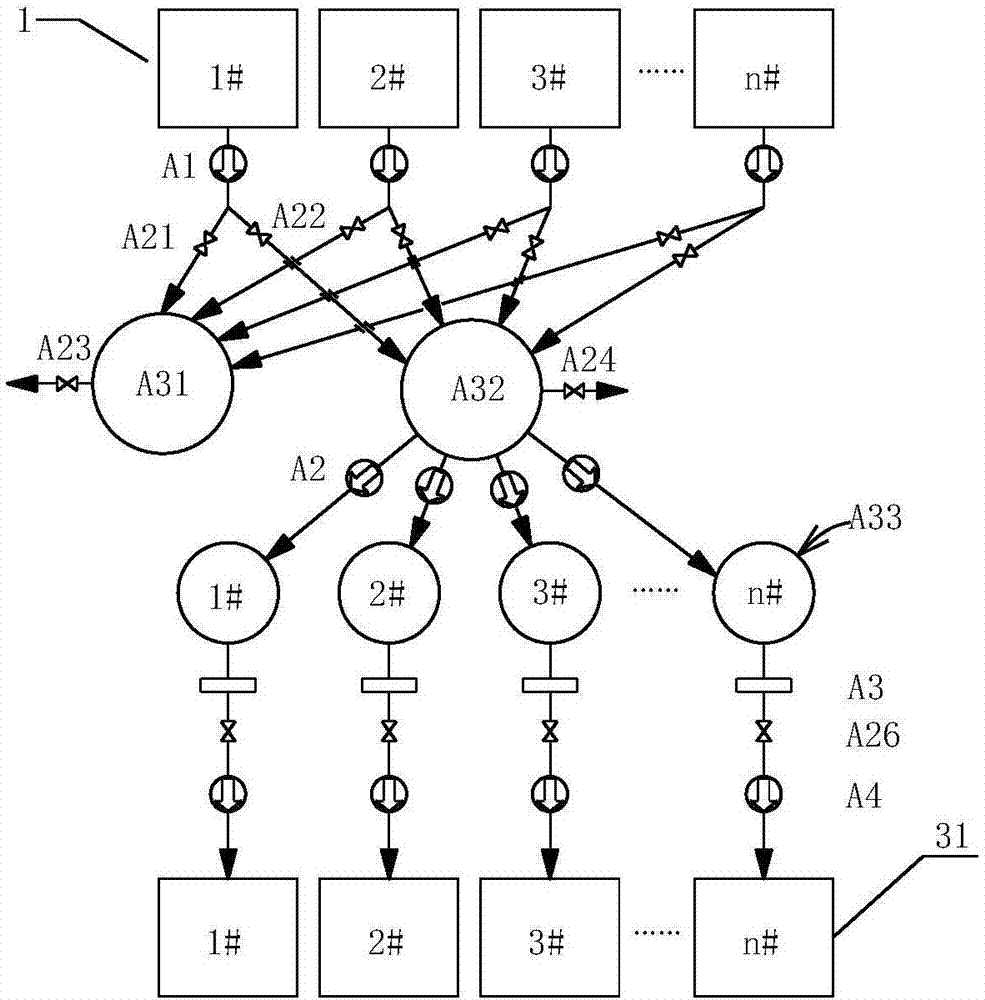

[0070] In this embodiment, the ash outlets of the pre-dust collectors 1 of multiple units are connected with a first-level distribution and conveying device A1, and the outlet of the first-level distribution and conveying device A1 of each unit is connected in parallel with an outer discharge conveying adjustment device A21 and a central discharge adjustment device A21. Storage and transportation adjustment device A22; each unit's external di...

Embodiment 2

[0080] In the system provided in Embodiment 1, the high-calcium fly ash sharing and resource utilization of a multi-unit power station is carried out. Taking a single 300MW unit of a certain power station as an example, the specific implementation is as follows:

[0081] The 300MW-scale circulating fluidized bed boiler provides raw flue gas. When the furnace is not desulfurized, the raw flue gas SO 2 The concentration is 2000mg / Nm 3 , SO in the raw flue gas after desulfurization in the furnace 2 The concentration is 480mg / Nm 3 , the flue gas temperature is 138°C, and the flue gas volume is 1,750,000m 3 / h. The CaO content in the high-calcium fly ash after furnace desulfurization is 15-23wt%. Transport high-calcium fly ash into the absorption tower, keep the operating temperature of the absorption tower at 85°C during operation, the pressure drop of the absorption tower bed layer is 1.1kPa, the consumption of high-calcium fly ash is 6.5t / h and the water consumption of the a...

Embodiment 3

[0083] In the system provided in Example 1, the high-calcium fly ash sharing and resource utilization of multi-unit power plants are carried out. Taking a self-provided power plant with 6×100MW circulating fluidized bed boiler units as an example, the sulfur dioxide content at the chimney inlet The requirement is not higher than 35mg / Nm 3 , the specific implementation is as follows:

[0084] Flue gas volume of each 100MW boiler working condition is 810000m 3 / h, wet standard flue gas volume 490000m 3 / h, dry standard flue gas volume 450000m 3 / h, SO in the raw flue gas without desulfurization in the furnace 2 The concentration is 4000mg / Nm 3 , the fly ash concentration in the raw flue gas is 20000mg / Nm when the furnace is not desulfurized 3 .

[0085] According to the test results of desulfurization in the furnace, when the calcium-sulfur ratio of desulfurization in the furnace is 1.0, the desulfurization efficiency in the furnace is 50%, and the CaO content in the fly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com