Processing technology of green tea with flower fragrance

A processing technology and green tea technology, applied in the field of floral green tea processing technology, can solve the problems of short rolling time, waste of concentrated liquid, masking of the original taste of green tea, etc., and achieve the effects of mellow taste, good taste and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

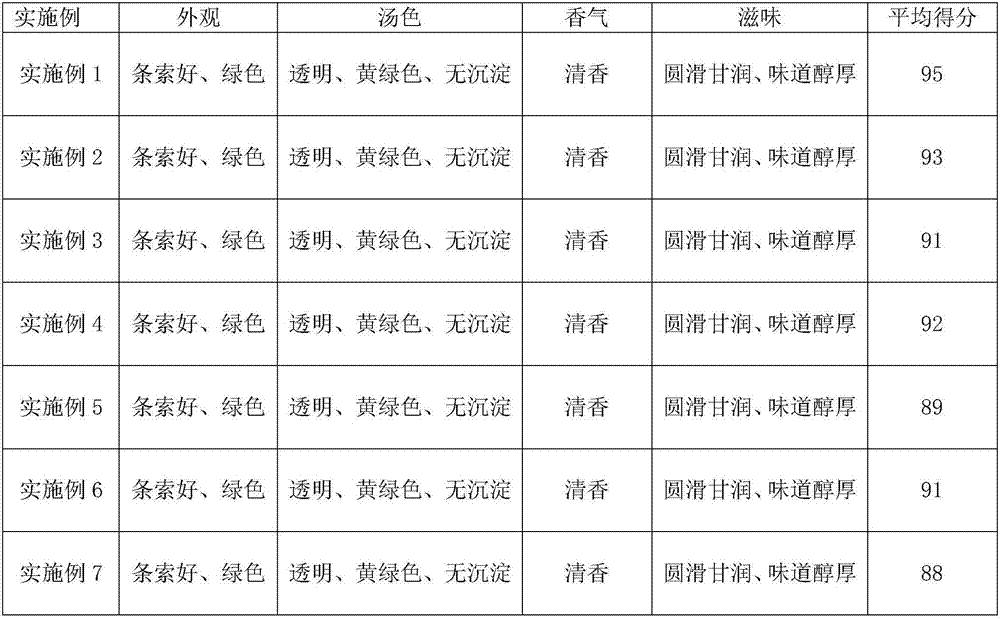

Examples

Embodiment 1

[0026] Step 1, fresh leaf treatment: take 100 kg of fresh leaves picked within 24 hours in parts by mass, wash with water and remove impurities, and dry the surface moisture of the tea leaves;

[0027] Step 2. Juice production: Take 12kg of fresh jasmine, 9kg of honeysuckle, 4kg of osmanthus, and 5kg of acacia flower in parts by mass, mix well and then pulverize, add 1.5kg of sugar, 12kg of clear water, stir well, cover and ferment for 7 hours, filter, take Juice, leaving a solid residue;

[0028] Step 3. Shake the greens: Use the greening machine to shake the greens continuously for 4 hours until the tea leaves become soft;

[0029] Step 4, finishing: place the tea leaves in the roller fixing machine, dilute the juice prepared in step 2 by 12 times, boil it at 0.92 standard atmospheric pressure, and pass the boiled water vapor into the roller fixing machine Inside, the roller rotates when finishing, until the juice evaporates completely, close the roller fixing machine, and ...

Embodiment 6

[0033] Embodiment 6: Compared with embodiment 1, the difference between embodiment 6 and embodiment 1 is that in step 3 of embodiment 6, after the roller de-greening machine is closed, the tea leaves are not stewed in the de-greening machine.

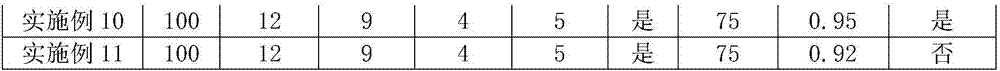

Embodiment 11

[0034] Embodiment 11: Compared with Embodiment 1, the difference between Embodiment 11 and Embodiment 1 is that Embodiment 11 directly uses an electric heater to dry the water content of the two tea leaves to 3-5% in step 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com