Disinfecting powder spraying and scattering machine for silkworms

A duster and dusting technology, applied in the fields of chemistry, animal husbandry, etc., can solve the problems of inability to popularize and apply, uneven spraying, and uncontrollable dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

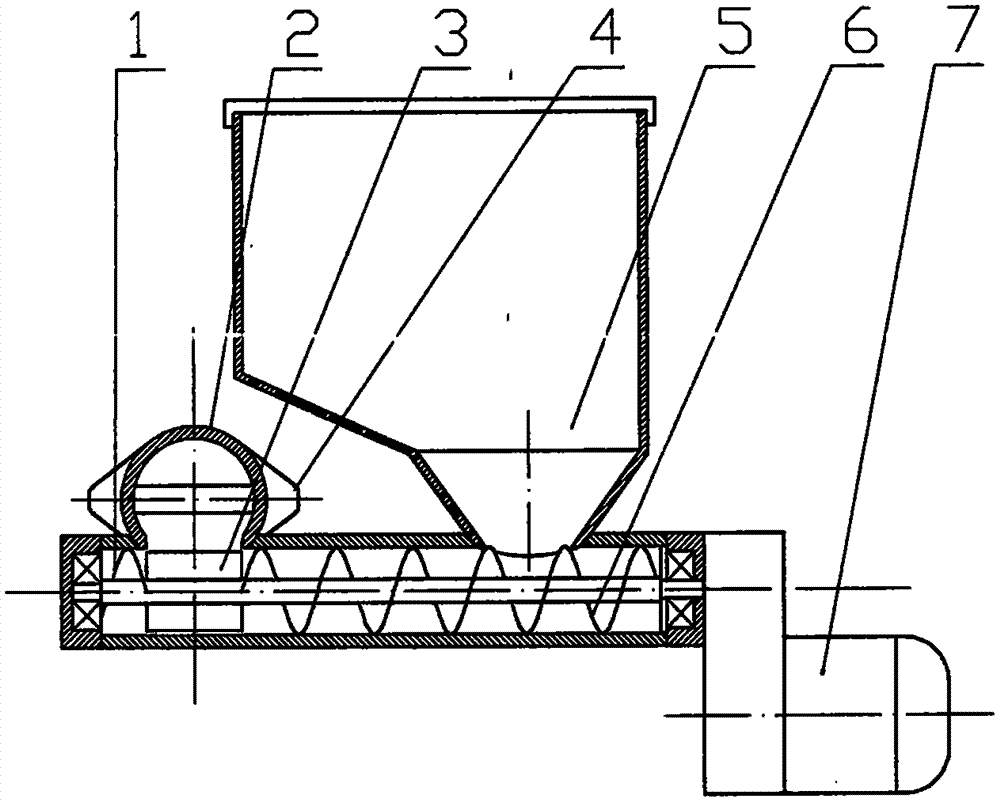

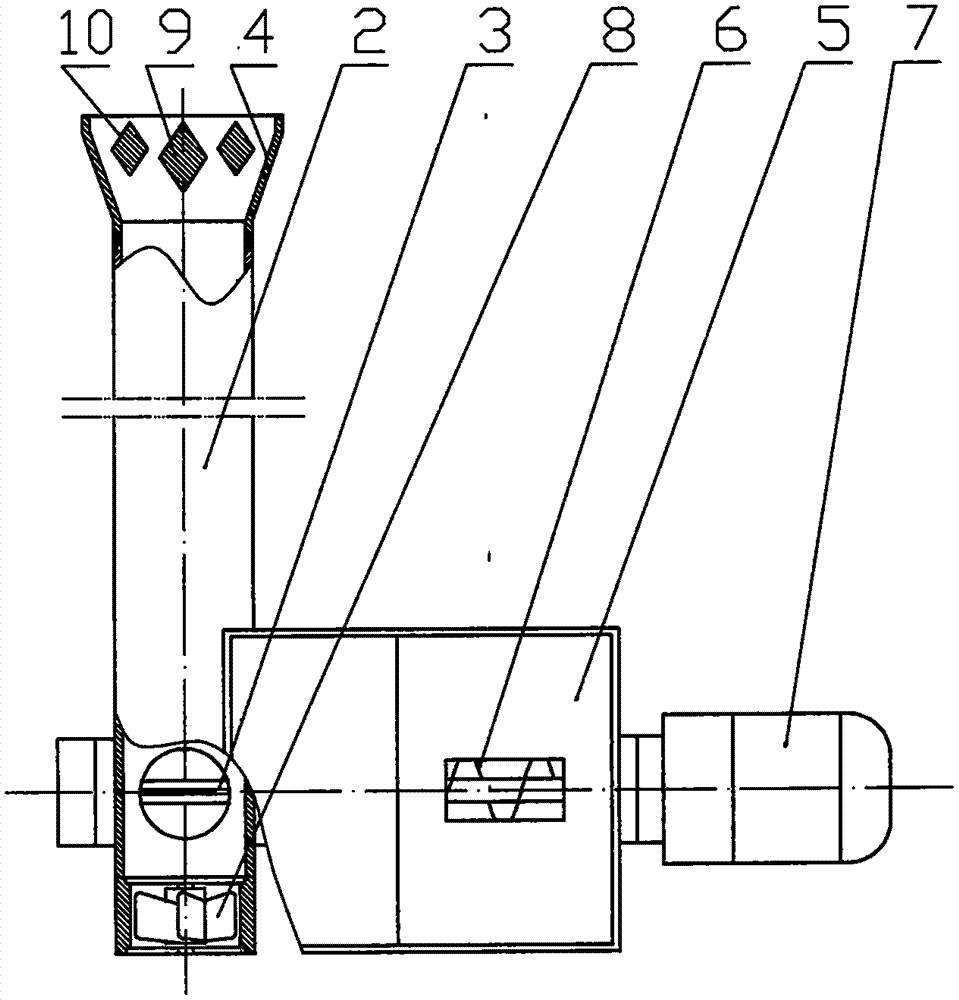

[0019] exist figure 1 with figure 2 In the shown silkworm disinfection powder spraying machine, the medicine powder hopper 5 is an offset funnel-shaped box body, and its bottom outlet is set off from the center. The shell of the feeding auger 6 is a cylinder, and the two sides of the feeding auger 6 The shaft end is rotatably supported in its shell, and the outlet at the bottom of the powder hopper 5 is connected to the inner cavity of the input end of the feeding auger 6; the feeding auger 6 is driven by an adjustable speed motor 7, which is a micro DC belt The speed-regulating motor of the deceleration mechanism can control the amount of powder output by changing the running speed of the feeding auger 6 through the speed-regulating motor to meet the different requirements of silkworms in different periods and different disinfectants on the amount of powder falling; the output end of the feeding auger 6 is set There are powder raising blades 3, the number of powder raising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com