Four-stroke diesel engine on farming tractor

A four-stroke, tractor technology, applied in the direction of machines/engines, fuel systems, mechanical equipment, etc., can solve problems such as the ability to resist compression and shock absorption, lower mechanical efficiency, and insufficient stability, so as to improve equipment stability and improve Kinetic energy, effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

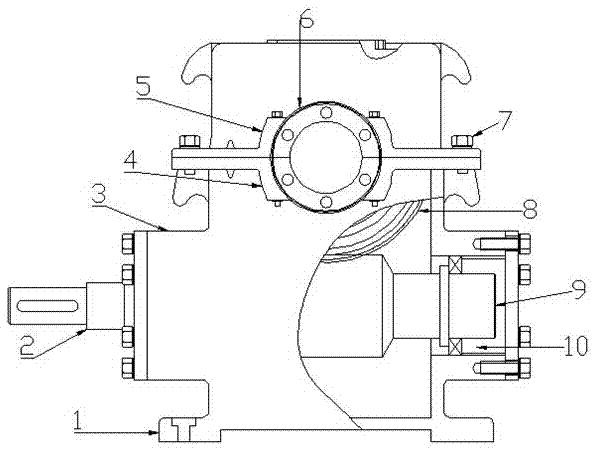

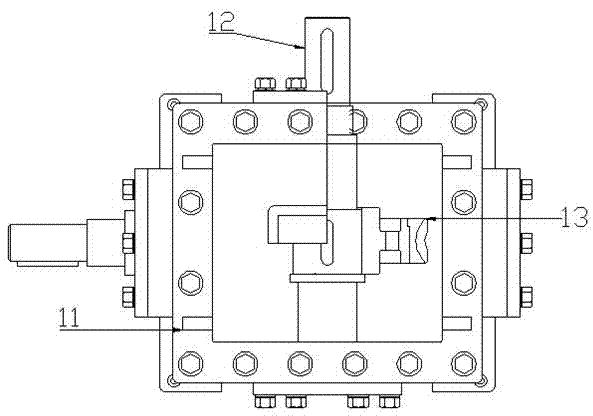

[0016] Such as Figure 1-Figure 2 As shown, a four-stroke diesel engine on an agricultural tractor includes a base 1, a protection crankshaft 4, a combustion chamber 8, and a graphite carbon rod 11. A connecting shaft 2 is arranged above the base 1, which can improve engine efficiency. The pressure-resistant plate 3 of the chassis improves stability. The pressure-resistant plate 3 of the chassis is set between the connecting shaft 2 and the protection crankshaft 4, which can avoid mechanical damage. A pressure crankshaft 5 is installed above the protection crankshaft 4, which can slow down the pressure on the equipment. The crankshaft 5 and the central axis of the cam 6 are on the same straight line to increase the braking force. The central axis of the cam 6 and the fixed bolt 7 are on the same straight line to increase the gas value. The fixed bolt 7 is installed above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com