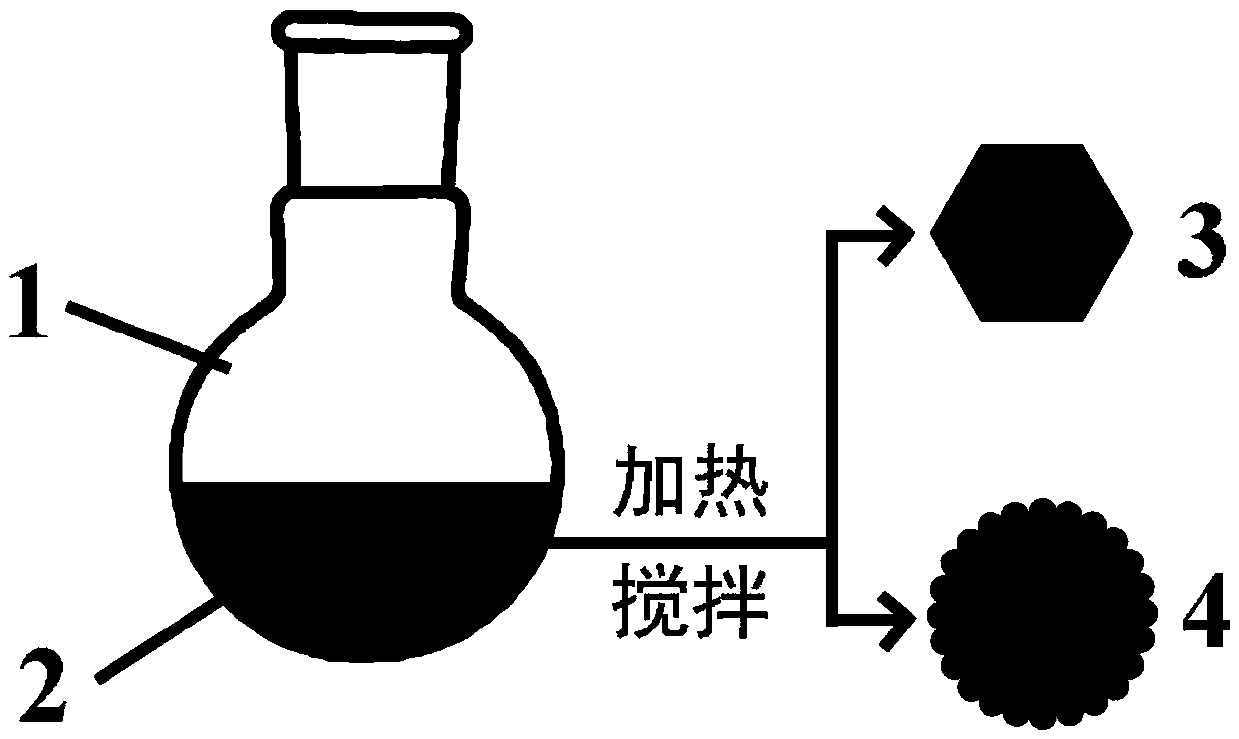

A method for rapid preparation of copper nanoparticles with controllable particle size and morphology

A technology of copper nanoparticles and particles, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of tedious and time-consuming synthesis process, harsh reaction conditions, etc., and achieve uniform shape, short reaction time and good biocompatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for rapidly preparing copper nanoparticles with controllable particle size and shape, the method comprising the following steps:

[0041] (1) Using ethylene glycol as a solvent, configure the ethylene glycol solution of ascorbic acid and the ethylene glycol solution of copper salt respectively; The copper salt selected in is copper sulfate pentahydrate, and the concentration of the ethylene glycol solution of copper sulfate pentahydrate prepared is 0.022 mol / liter.

[0042] (2) Add the ethylene glycol solution of ascorbic acid, the ethylene glycol solution of copper salt, and an appropriate amount of alkali solution prepared in step (1) in sequence in the container, stir and heat for reaction. The temperature of the heating reaction is 85°C. The time is 30 minutes;

[0043] Wherein, the volume of the ethylene glycol solution of the ascorbic acid that adds and the ethylene glycol solution of the copper sulfate pentahydrate that add are equal, are 6 milliliters;...

Embodiment 2

[0048] A method for rapidly preparing copper nanoparticles with controllable particle size and shape, the method comprising the following steps:

[0049] (1) Using ethylene glycol as a solvent, configure the ethylene glycol solution of ascorbic acid and the ethylene glycol solution of copper salt respectively; The copper salt selected in is copper sulfate pentahydrate, and the concentration of the ethylene glycol solution of copper sulfate pentahydrate prepared is 0.03 mol / liter.

[0050] (2) Add the ethylene glycol solution of ascorbic acid, the ethylene glycol solution of copper salt, and an appropriate amount of alkali solution prepared in step (1) in sequence in the container, stir and place in an oil bath for heating reaction. The heating reaction temperature is 85°C, the heating reaction time is 30 minutes;

[0051] Wherein, the volume of the ethylene glycol solution of the ascorbic acid that adds and the ethylene glycol solution of the copper sulfate pentahydrate that ...

Embodiment 3

[0057] A method for rapidly preparing copper nanoparticles with controllable particle size and shape, the method comprising the following steps:

[0058] (1) Using ethylene glycol as a solvent, configure the ethylene glycol solution of ascorbic acid and the ethylene glycol solution of copper salt respectively; The copper salt selected in is copper sulfate pentahydrate, and the concentration of the ethylene glycol solution of copper sulfate pentahydrate prepared is 0.03 mol / liter.

[0059] (2) Add the ethylene glycol solution of ascorbic acid, the ethylene glycol solution of copper salt, and an appropriate amount of alkali solution prepared in step (1) in sequence in the container, stir and heat for reaction. The temperature of the heating reaction is 85°C. The time is 30 minutes;

[0060] Wherein, the volume of the ethylene glycol solution of the ascorbic acid that adds and the ethylene glycol solution of the copper sulfate pentahydrate that add are equal, are 6 milliliters; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com