A kind of porous carbon material SO2 electrochemical oxidation catalyst and its preparation method and application

A technology of porous carbon materials and oxidation catalysts, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of low activity and low activity, increase electrochemical oxidation ability, and increase micropore content and specific surface area, important application value and use prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The desulfurization performance of the catalyst was tested in a three-electrode system. The coated disk electrode was heated in 0.5M H 2 SO 4 Cyclic voltammetry (CV) activation: CV-100mV / s-15 cycles, 3 times; test initial activity: CV-50mV / s-3 cycles; constant potential (CA) 0.8V test desulfurization performance: CA-0.8V -High-speed rotation-1600r / min, after 10 minutes, quickly stop and start to remove the charging current, continue the constant potential test, add 10mL of 1g / L Na prepared by 0.5M sulfuric acid to the system after 10 minutes with a syringe with a thin soft catheter 2 SO 3 solution, in N 2 In the double stirring system of disturbance and 1600r / min rotation, the catalyst reacts to a certain amount of SO at 0.8V 2 Generate an instantaneous current step response. Change the constant potential value to test the catalytic desulfurization performance of the catalyst at 1.2V. Comparison of the desulfurization performance of 20% Pt / C and prepared catalysts...

Embodiment 2

[0039] The desulfurization performance of the catalyst was tested in a three-electrode system, and the electrodes were exposed to 0.5M H 2 SO 4 Activate in: CV-100mV / s-15 circles, 3; test the initial activity CV-50mV / s-3 circles; replace the electrolyte solution with 1g / L Na prepared by 0.5M sulfuric acid 2 SO 3 Solution, electrode rotation speed 1600r / min, linear voltage scanning rate 5mV / s, compare the desulfurization performance of 20% Pt / C and prepared catalyst at different potentials as figure 2 As shown, it can be seen that although the desulfurization performance of the prepared catalyst is relatively low compared with Pt at a lower potential, it already has an obvious catalytic oxidation of SO 2 Excellent performance, strong desulfurization ability at high potential.

Embodiment 3

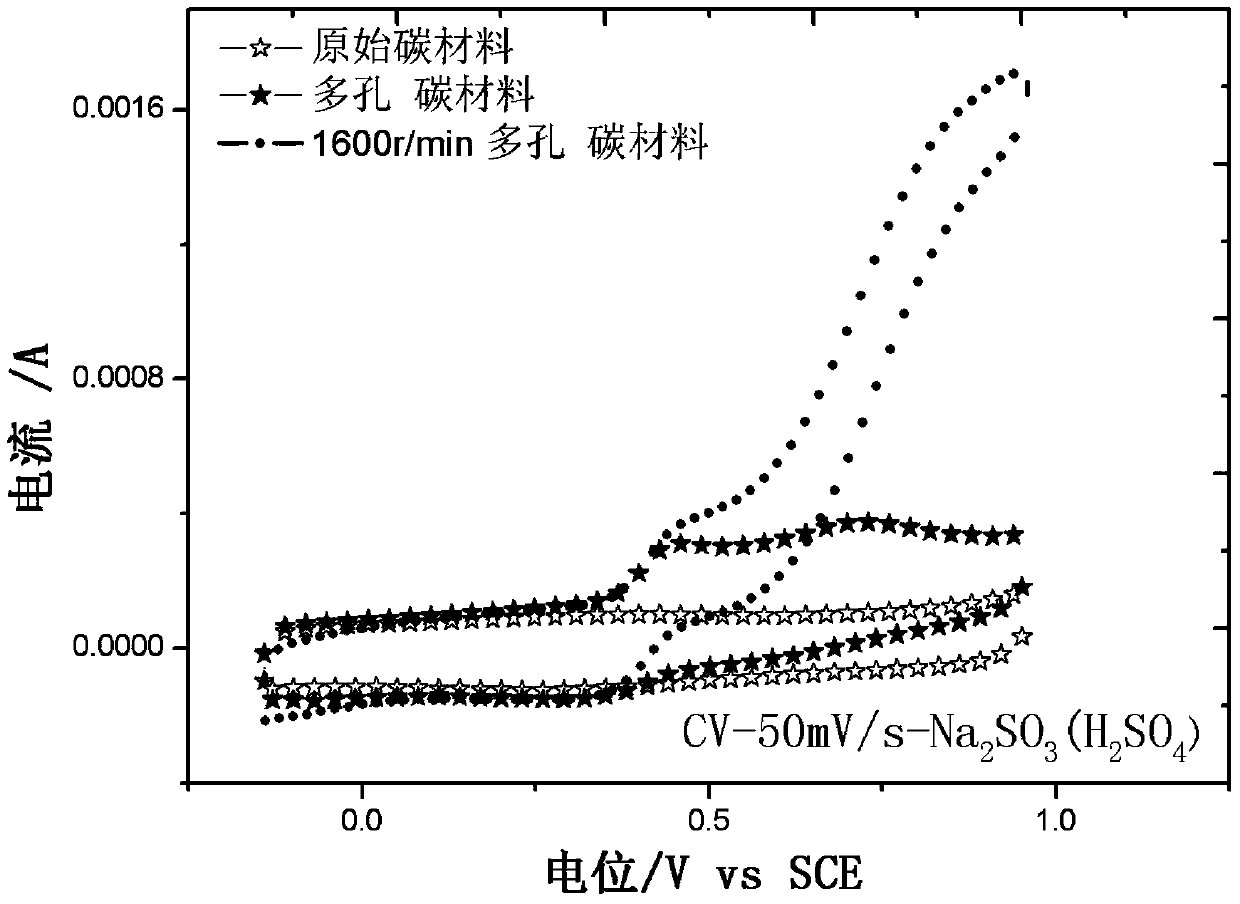

[0041] The desulfurization performance of the catalyst was tested in a three-electrode system, and the electrodes were exposed to 0.5M H 2 SO 4 Medium activation: CV-100mV / s-15 circles, 3 times; test the initial activity CV-50mV / s-3 circles; replace the electrolyte solution with 1g / L Na prepared by 0.5M sulfuric acid 2 SO 3 Solution, carry out CV test; rotate the electrode 1600r / min, test the desulfurization performance of the catalyst, the test results are compared with image 3 As shown, it can be seen that the prepared catalyst has a positive effect on SO 2 It has obvious electrochemical oxidation ability, and its desulfurization ability is greatly enhanced when the electrode rotates at high speed. On the one hand, during the rotation process, the adsorption products on the electrode surface can be quickly detached, which is beneficial to the subsequent reaction; on the other hand, due to the high-speed rotation process, the concentration difference of the reactants on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com