Rigid-flex board and manufacturing method thereof

A technology of rigid-flex board and manufacturing method, which is applied in the structural connection of printed circuit, printed circuit parts, and assembling printed circuit with electrical components, etc. The effect of shrinking the extreme difference, avoiding layer deviation, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a rigid-flex board and its manufacturing method. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

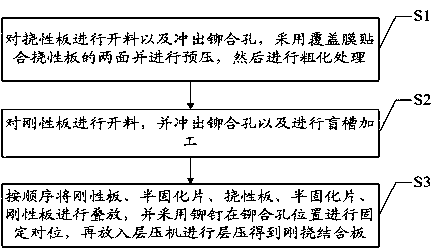

[0027] see figure 1 , figure 1 It is a flow chart of a preferred embodiment of a method for manufacturing a rigid-flexible board of the present invention, as shown in the figure, which includes steps:

[0028] S1. Cut the flexible board and punch out the riveting holes, use the cover film to fit the two sides of the flexible board and pre-press, and then perform roughening treatment;

[0029] S2. Cutting the rigid plate, punching out the riveting hole and processing the blind groove;

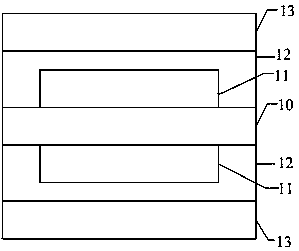

[0030] S3. Stack the rigid board, prepreg, flexible board, prepreg, and rigid board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com