A Taper Sleeve Adaptive External Support for Twenty-Roll High Tension Rolling

An adaptive, 20-roll technology, applied in the field of auxiliary support devices for coilers in rolling production lines, can solve problems such as poor stability, high wear, and low rigidity, and achieve high stability, long service life, and good rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

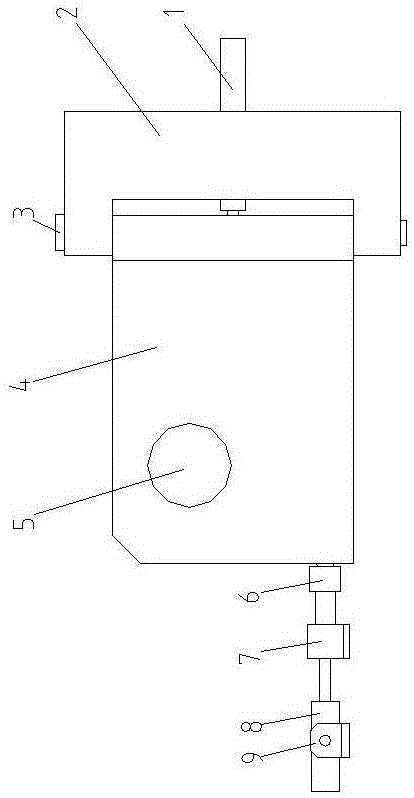

[0024] In order to overcome the problems of high wear, low rigidity and poor stability of existing devices, the present invention provides such as figure 1 and figure 2 The shown one kind of taper sleeve self-adaptive external support for 20-high high-tension rolling, that is, a kind of swing door fixed at both ends, taper sleeve self-adaptive external support, the support has high rigidity and good stability, and can It can automatically align and compensate the wear gap, and can accurately position and limit the cantilever end of the reel. It is suitable for the outer support of the high-tension coiler in the 20-high rolling production line.

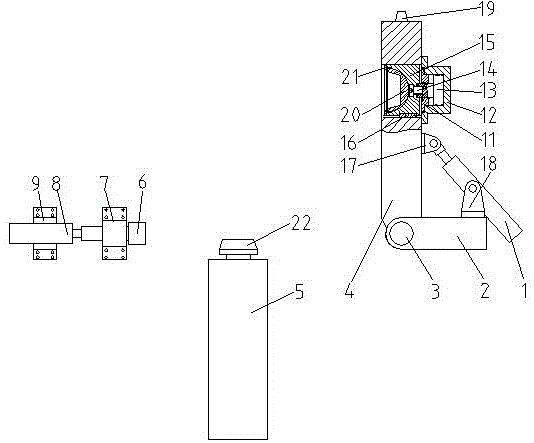

[0025] Such as figure 2 As shown, a taper sleeve self-adaptive outer support for 20-high high-tension rolling includes a swing cylinder 1, a bracket 2, and a swing door 4, and the swing cylinder 1 passes through a base 18 arranged on the bracket 2 Fixedly installed on the bracket 2, the piston rod of the swing cylinder 1 is hinged ...

Embodiment 2

[0032] Based on the first embodiment, the outside of the spherical taper sleeve 20 in this embodiment is processed with a tapered hole, the taper of which is the same as that of the cantilever head 22 of the reel 5 . The tapered hole provided can replace the cantilever head 22 to prevent the wear of the cantilever head 22. This tapered sleeve type can fully fit with the cantilever end of the reel, with accurate positioning and good stability.

[0033] The sliding column 15 is provided with a retaining ring 21 to prevent the spherical taper sleeve 20 from falling out.

[0034] Spherical tapered sleeve 20 is installed inside sliding column 15, and its convex spherical surface is equal to the curvature of the spherical surface of sliding column 15. The outer side of spherical surface taper sleeve 20 is processed with a tapered hole, and its taper is the same as that of the cantilever head 22 of reel 5. When the swing door 4 is closed, the two cone surfaces fit together, and the r...

Embodiment 3

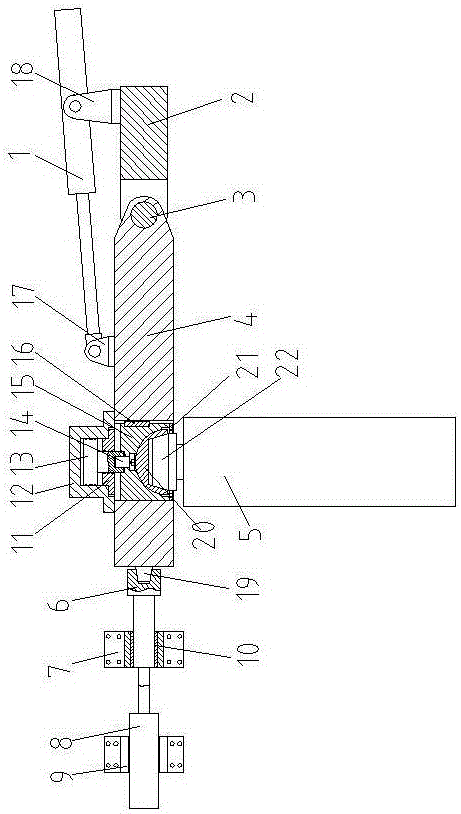

[0039] Based on the above two embodiments, as image 3 As shown, in the waiting position, the swing cylinder 1 is retracted, the swing door 4 is in an open state, the piston rod 13 is in a retracted state, the locking cylinder 8 is in a retracted state, and the connected locking rod is also in a retracted state. When working, after the diameter expansion of the reel 5 is completed, the piston rod of the swing cylinder 1 is stretched out, and the swing door 4 is pushed to close. After the closing is in place, the piston rod of the locking cylinder 8 is stretched out, and the locking rod 6 is pushed to be set on the taper pin 19, and the swing door 4 is pushed out. The door 4 is locked, and then the piston rod 13 is stretched out, driving the sliding column 15 and the spherical taper sleeve 20 to slide towards the cantilever head 22, utilizing the adaptability of the spherical surface, the spherical taper sleeve 22 is tightly set on the cantilever head 22, and the axial and Radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com