Motor drive system based on sliding-mode observer

A technology of motor drive system and sliding mode observer, used in motors, electric vehicles, control systems, etc., can solve the problems of unstable vehicle speed, reduced system reliability, and large loss of switching tubes, so as to ensure smooth operation and improve response. speed, the effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the above-mentioned and other purposes, features and advantages of the present invention will be clearer. Like reference numerals designate like parts throughout the drawings. The drawings have not been drawn to scale, emphasis instead being placed upon illustrating the gist of the invention.

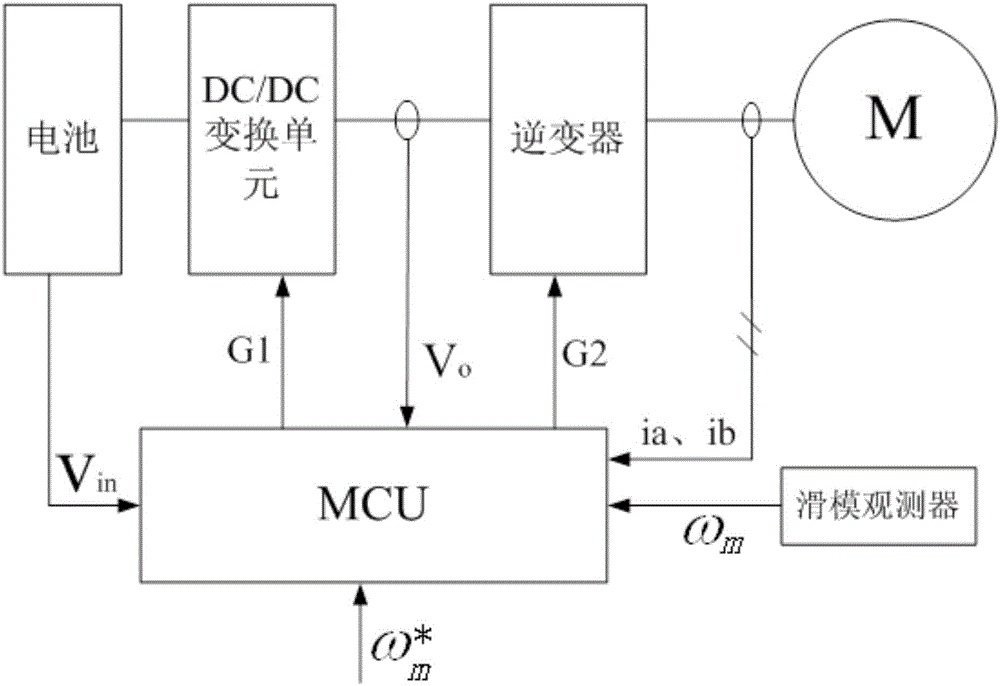

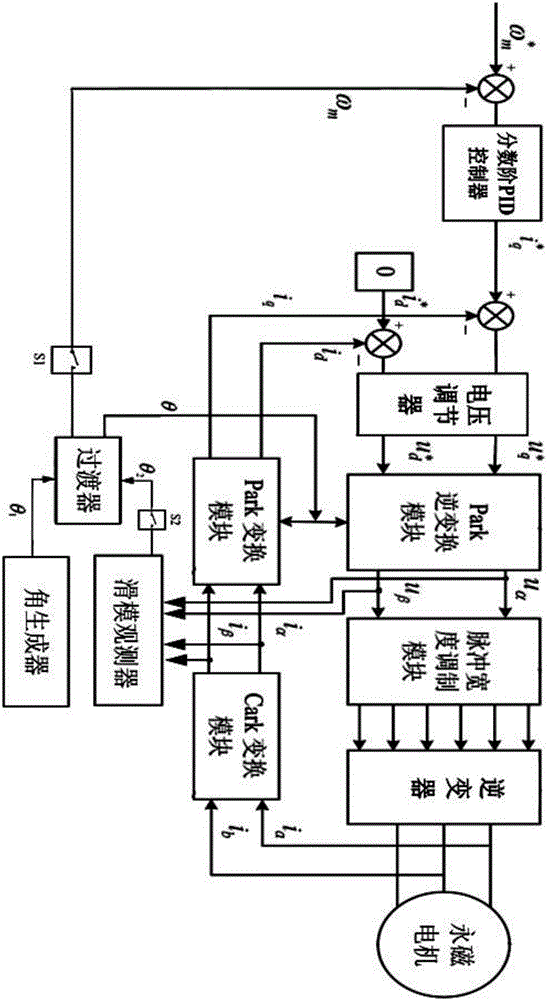

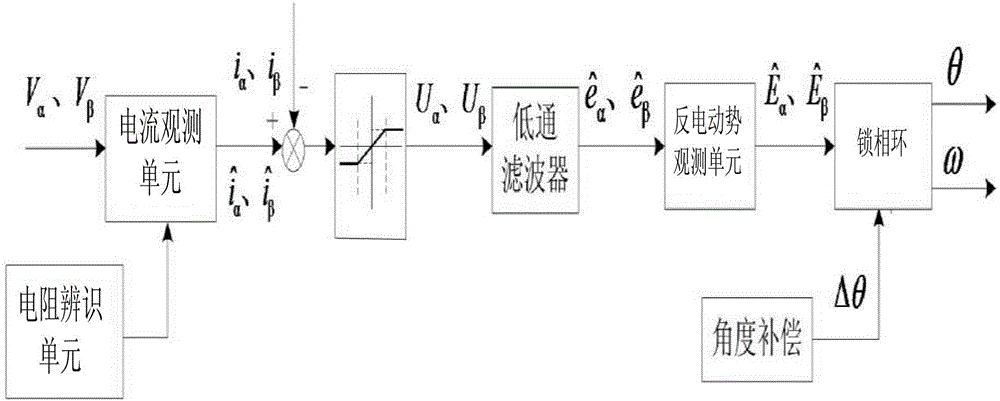

[0016] first combined with figure 1 The system structure of the present invention will be described. The invention provides an electric vehicle driving system, which includes: a DC / DC conversion unit, an inverter, a permanent magnet motor, an MCU (main control unit), an angle generator, a sliding mode observer and the like. The DC / DC conversion unit is connected to the battery, the output end of the DC / DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com