High-power column vector fiber laser based on linear pseudolaser cavity

A fiber laser and laser cavity technology, applied in lasers, laser components, phonon exciters, etc., to achieve the effects of high output power, continuous and stable operation, and stable mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0023] The invention is a column vector light generation method of a fiber laser constructed by using a few-mode optical fiber engraved with a grating, and a pseudo-linear cavity is formed by vertical cutting and a few-mode grating. The output column vector optical power is larger and the purity is higher. The specific technical solutions of the present invention are briefly described below.

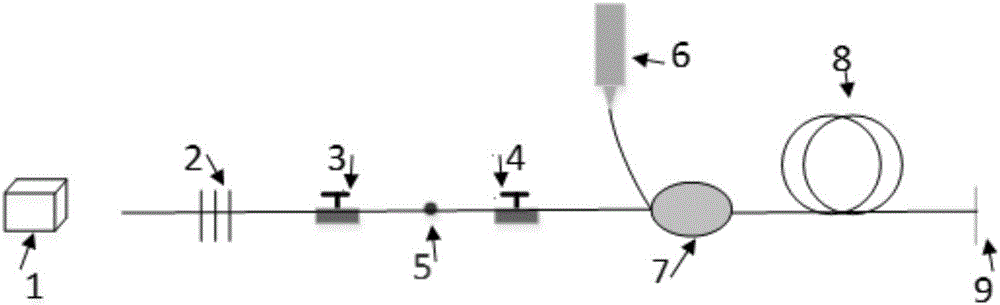

[0024] Such as figure 1 Shown is a schematic structural diagram of the present invention, a high-power column vector fiber laser based on a linear pseudolaser cavity, including a pump source, a signal / pump beam combiner, a double-clad ytterbium-doped fiber, and a few-mode fiber laser engraved with a grating An optical fiber, a first polarization controller, and a second polarization controller; wherein,

[0025] The output end of the pump source is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com