Miniature high-low frequency hybrid self-detachment connector

A self-dropping, high-low frequency technology, applied in the connection, the parts of the connecting device, the coupling device, etc., can solve the problems of low safety, unable to achieve self-dropping, etc., and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further description will be made below in conjunction with drawings and embodiments.

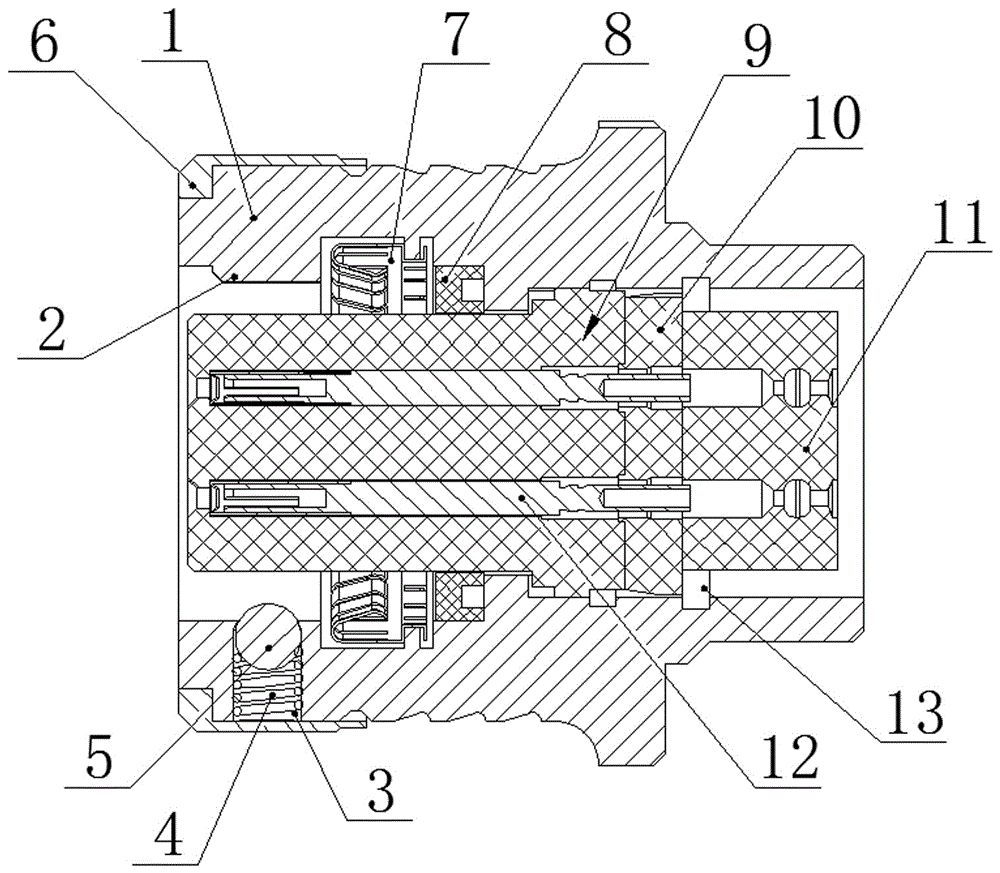

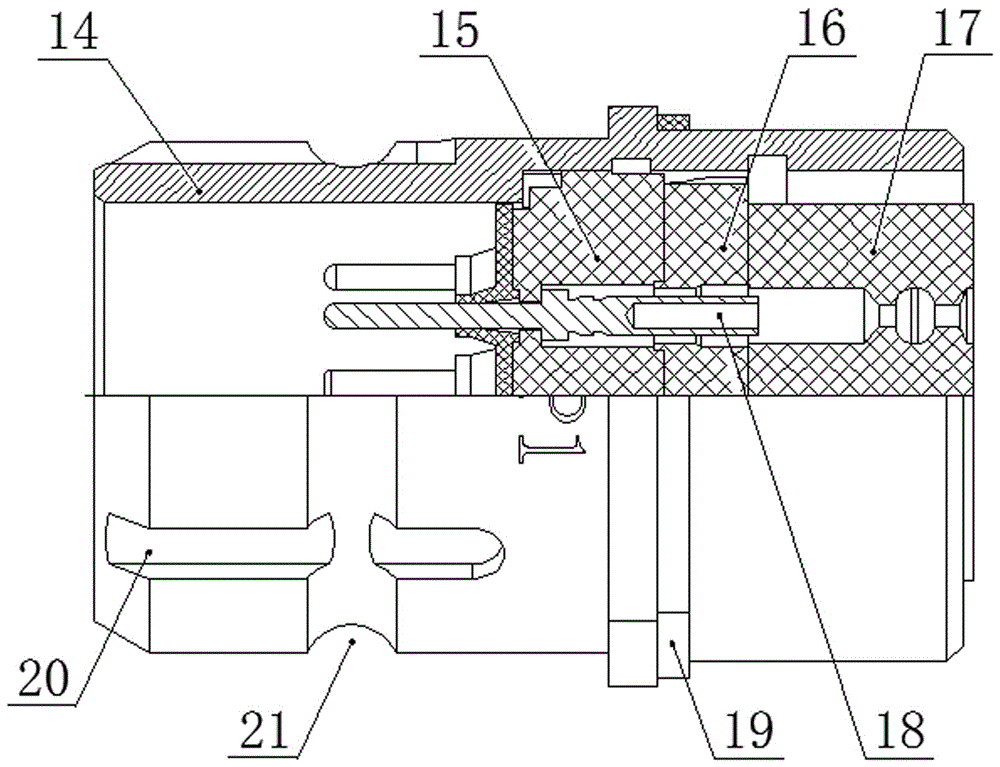

[0010] figure 1 , 2 Shown: a high and low frequency mixed small self-disconnecting connector, including a plug and a socket. Hole silicone rubber sealing body 11, shielding claw 7, sealing ring 8, steel ball 5, spring 4, a plurality of jack components 12 are sequentially connected to jack insulating plate 9, jack insulating plate cover plate 10, Inside the jack silicone rubber sealing body 11, the jack insulating plate, the jack insulating plate cover, and the jack silicone rubber sealing body are connected in the plug shell 1 from front to back in sequence, and the front end of the plug shell 1 is on the inner cavity wall. There are more than one guide key 2 and more than one radial locking through hole 3, and the radial locking through hole 3 is provided with steel balls 5 and springs 4 sequentially from the inside to the outside, and the inner opening of the radial locking throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com