Voltage reduction method and voltage reduction circuit of battery pack

A battery pack and circuit technology, which is applied in the direction of circuits, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of increasing product design volume, increasing design difficulty, increasing product development cost, etc., and achieving low energy loss , improve stability and safety, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

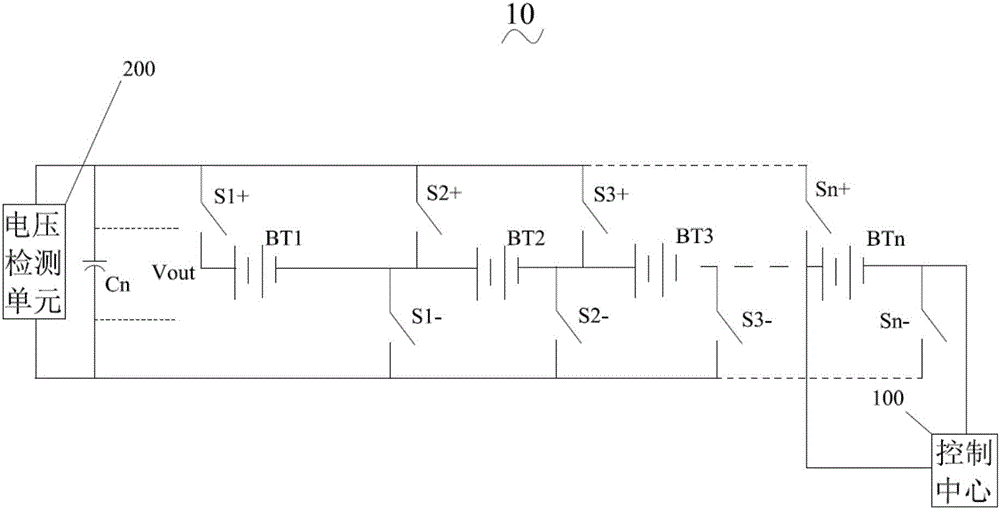

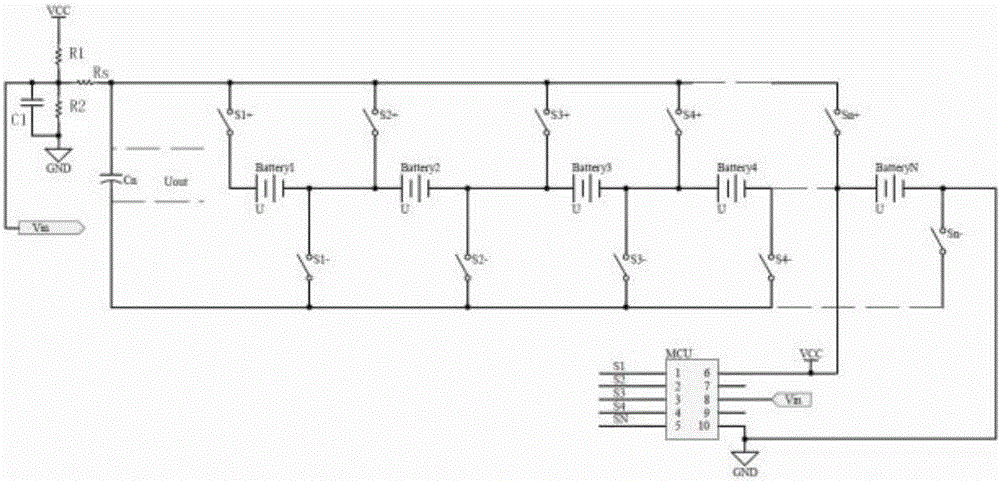

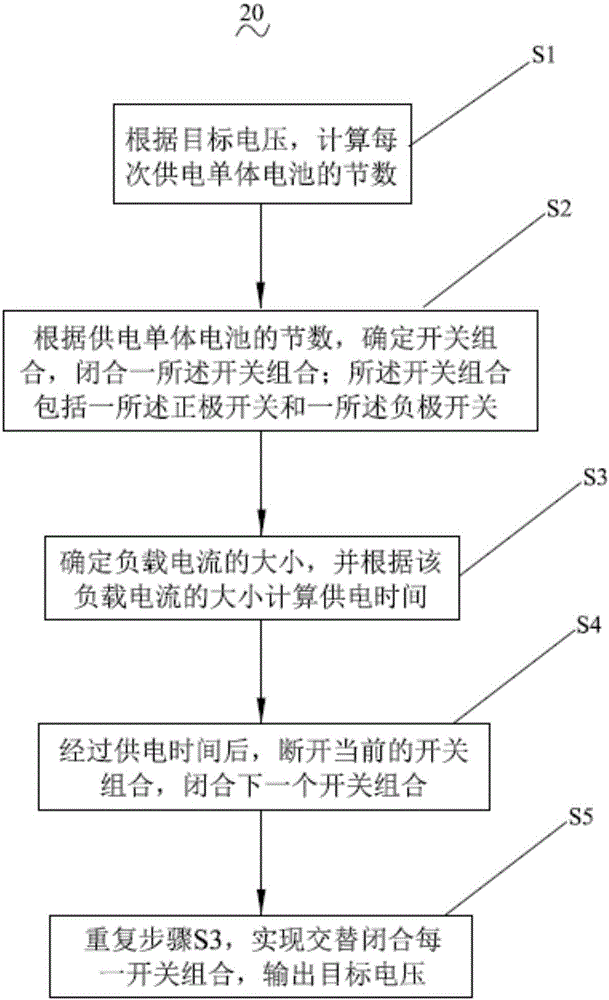

[0052] Please also refer tofigure 1 with figure 2 , The present invention provides a battery pack step-down circuit 10 comprising: a battery pack composed of a plurality of single cells connected in series, several positive switches, several negative switches, an output capacitor and a control center.

[0053] The first end of each positive pole switch is connected to the positive pole of a single battery, and the second end is respectively connected to one end of the output capacitor and a control terminal of the control center; the first end of each negative pole switch is connected to a single battery connected to the negative pole of the output capacitor, and the second end is respectively connected to the other end of the output capacitor and the other control end of the control center; both ends of the output capacitor are respectively connected to the first voltage output end and the second voltage output end. Further, the control center is an MCU, and the MCU receives...

Embodiment 2

[0068] see again figure 1 , the present invention also provides a battery pack step-down circuit, comprising: a battery pack composed of multiple single cells connected in series, several positive switches, several negative switches, an output capacitor Cn and a control center 100 .

[0069] The single battery BT provides power for the load circuit, the positive switch is used to control the positive output of the single battery BT, the negative switch is used to control the negative output of the single battery, and the output capacitor Cn is used to filter the ripple at the moment of switch switching. The control center 100 is used to control the closing or opening of the positive switch and the negative switch. The control center is MCU. The positive switch and the negative switch are relays or MOS tubes. The output capacitor is composed of several single capacitors connected in parallel.

[0070] The first terminal of each positive switch is connected to the positive te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com