Preparation method of efficient oxygen reduction catalyst with insect wings as substrate

A technology of catalysts and wings is applied in the field of preparing high-efficiency oxygen reduction catalysts, which can solve the problems of high preparation cost, poor stability, and low catalytic activity of catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

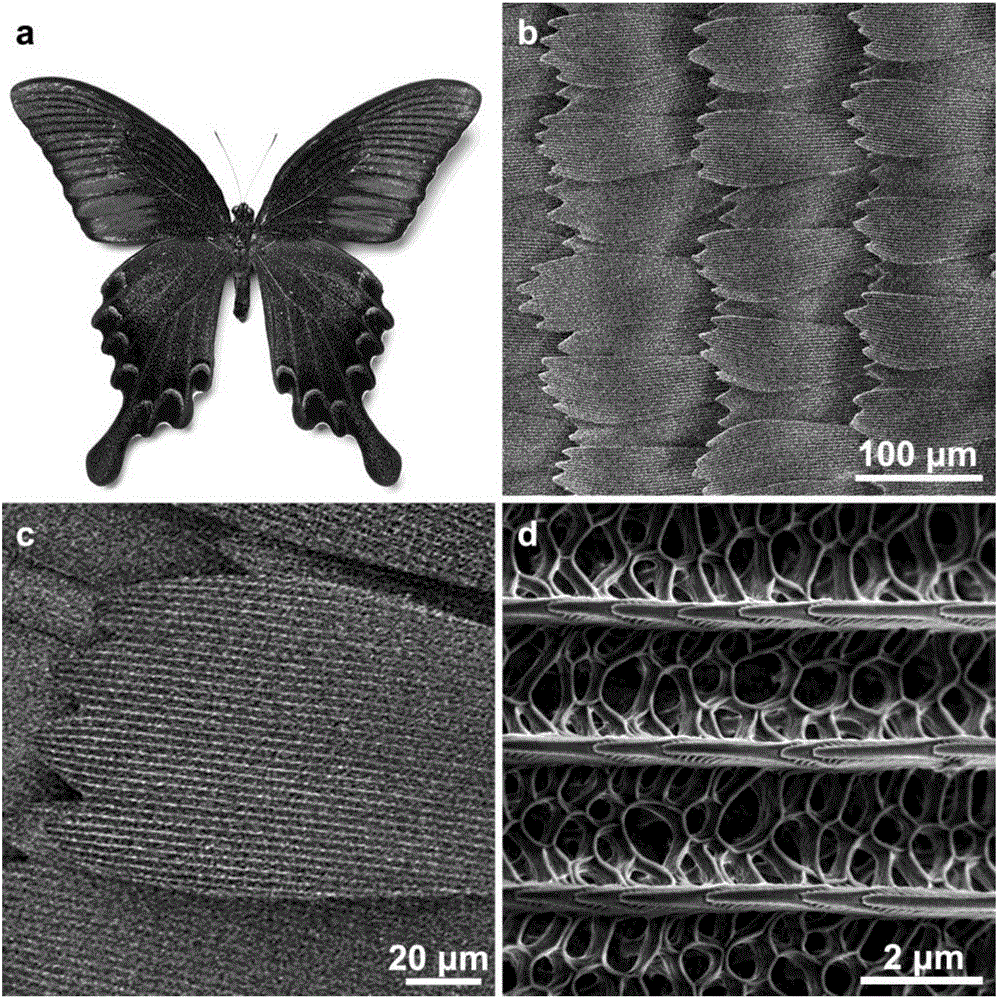

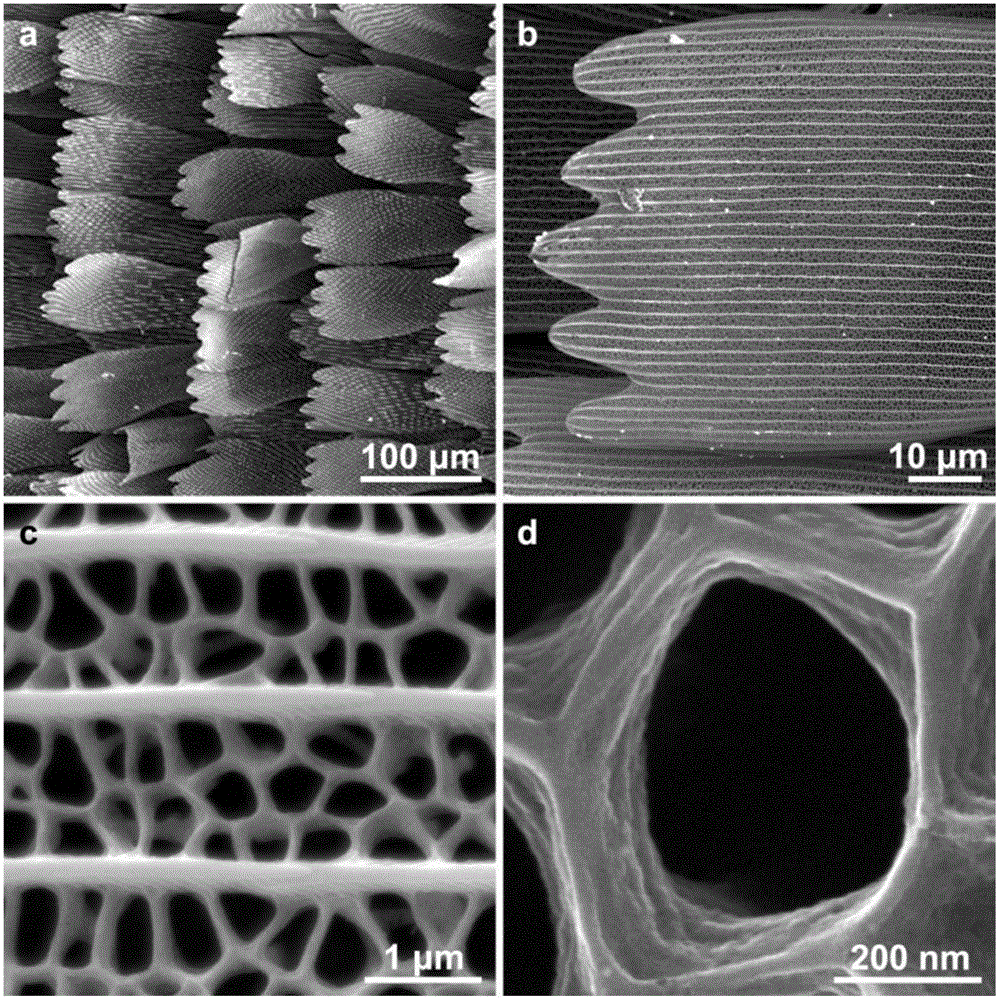

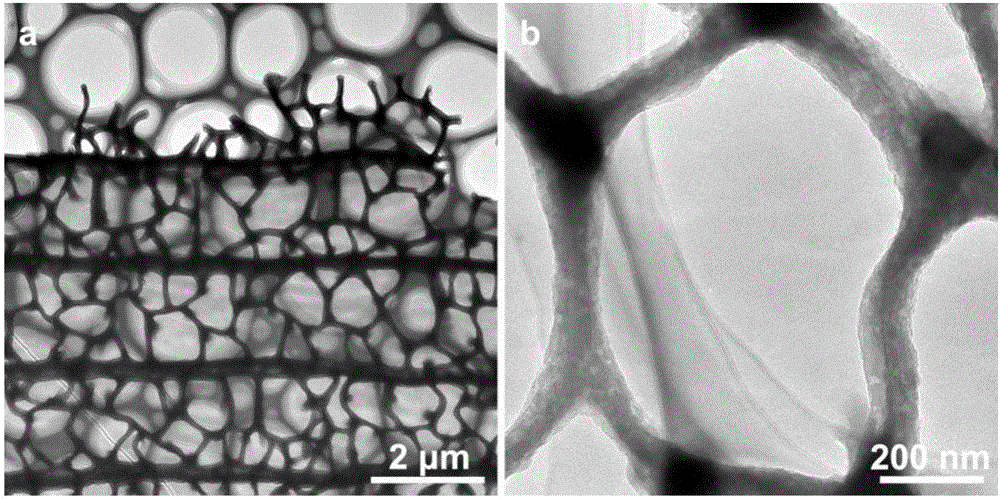

[0036] The insect species is green-belt jasmine, iron-containing compound is ferric chloride, cobalt-containing compound is pyridine cobalt, nitrogen-containing compound is melamine, and carbon black is BP2000.

[0037] Specific steps are as follows:

[0038] (1) Take 10 pieces of green-banded phoenix butterfly wings, about 0.1 g, and put them into a reaction kettle containing 30 ml of ultrapure water, and heat them in an oven for 2 hours at a temperature of 100°C. After cooling to room temperature, take out the butterfly wings, wash them with ultrapure water, and put them in an oven at 60℃ to dry for 8 hours;

[0039] (2) Take 0.1 g of carbon black BP2000, put it into a beaker containing 500 ml of ultrapure water, and perform ultrasonic treatment in an ultrasonic cleaner for 8 hours at a temperature of 25°C. After the ultrasonic treatment, centrifuge with a centrifuge to remove the supernatant, and centrifuge again with ultrapure water to clean 3 times. After the centrifugation, pu...

Embodiment 2

[0055] The insect species is green belt jasmine, the iron-containing compound is ferric nitrate, the cobalt-containing compound is pyridine cobalt, the nitrogen-containing compound is melamine, and the carbon black is BP2000.

[0056] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the ferric chloride in step 3 is replaced with ferric nitrate. The electrocatalytic material prepared by this scheme has good oxygen reduction catalytic performance.

Embodiment 3

[0058] The insect species is green-belt jasmine, the iron-containing compound is ferric chloride, the cobalt-containing compound is pyridine cobalt, the nitrogen-containing compound is melamine, and the carbon black is BP2000.

[0059] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the cobalt pyridine in step 3 is replaced with cobalt nitrate. The electrocatalytic material prepared by this scheme has good oxygen reduction catalytic performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com