Numerical method for rapidly predicting interconnection transmission characteristics of coupled through glass via

A technology of through-glass holes and transmission characteristics, which is applied in the field of electronics and can solve the problems of reducing signal transmission quality, increasing bit error rate of high-speed signal transmission, and not considering the coupling effect of target signal vias adjacent to signal vias, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0063] The numerical method for quickly predicting the transmission characteristics of coupled through glass via interconnection according to the embodiment includes the following steps:

[0064] (1) Record process node: read the top-level planning file in the early stage of 3D integrated circuit design, and record the process node information of the file;

[0065] (2) Storing the design parameters of tapered through-glass vias: According to the process node information, read the size parameters and material parameters of the through-glass vias corresponding to the process node in the ITRS data table, and store them as the design parameters of the through-glass vias. Design parameters include bottom hole radius, top hole radius, via height, hole spacing between vias, and electrical conductivity of the substrate;

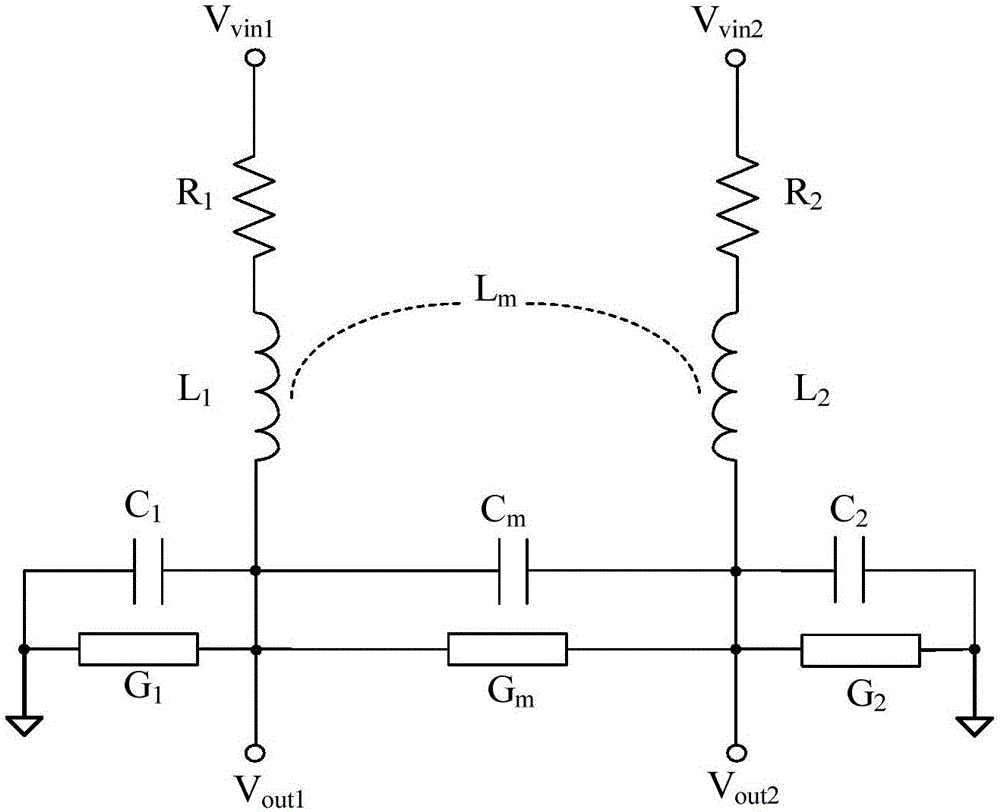

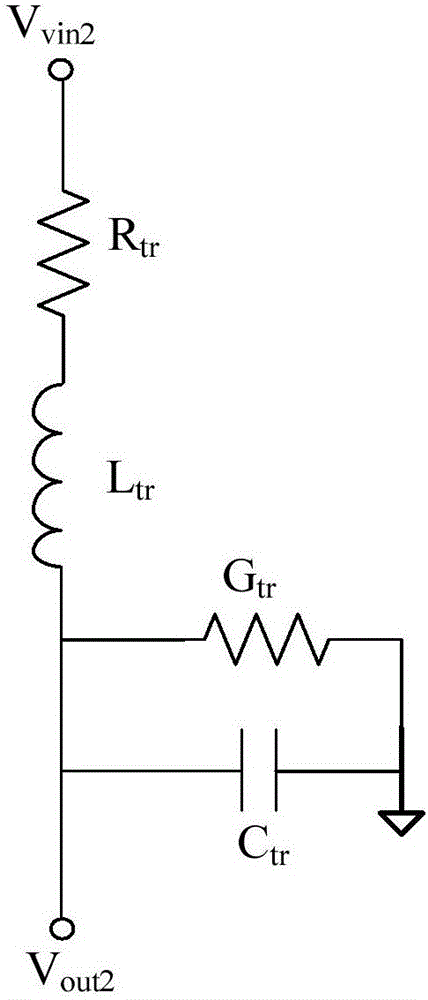

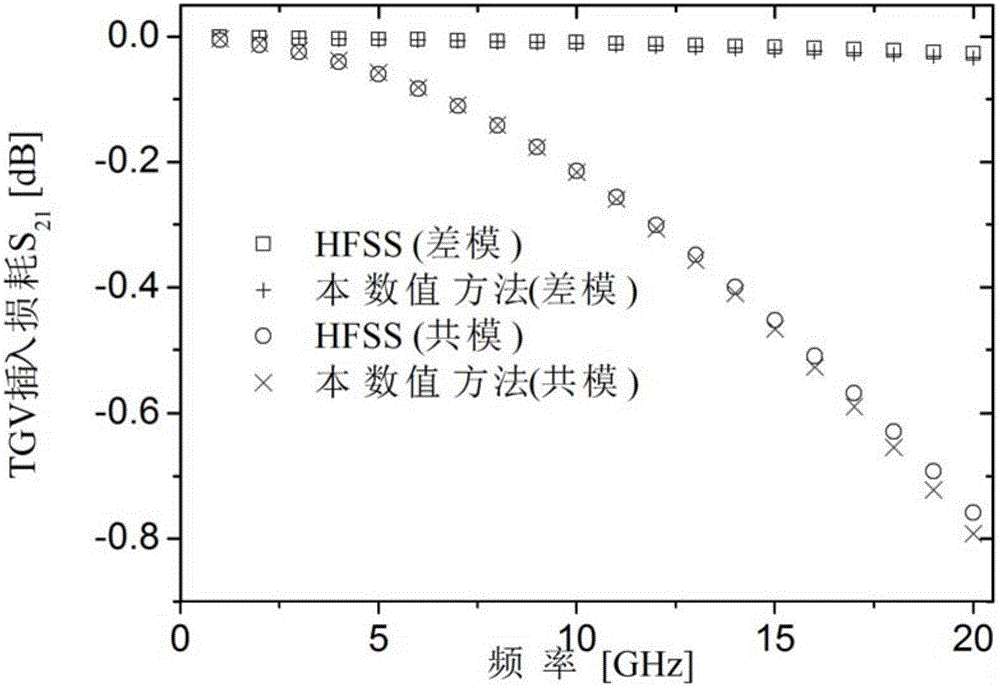

[0066] (3) Solve the electri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap