Rubbing-cloth aging equipment and control method

A technology of aging equipment and control method, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problem that the rubbing cloth cannot remove foreign matter in the rubbing cloth, and achieve the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0048] An embodiment of the present invention provides a rubbing cloth aging device, which can effectively remove foreign matters remaining in the rubbing cloth during the rubbing cloth aging process.

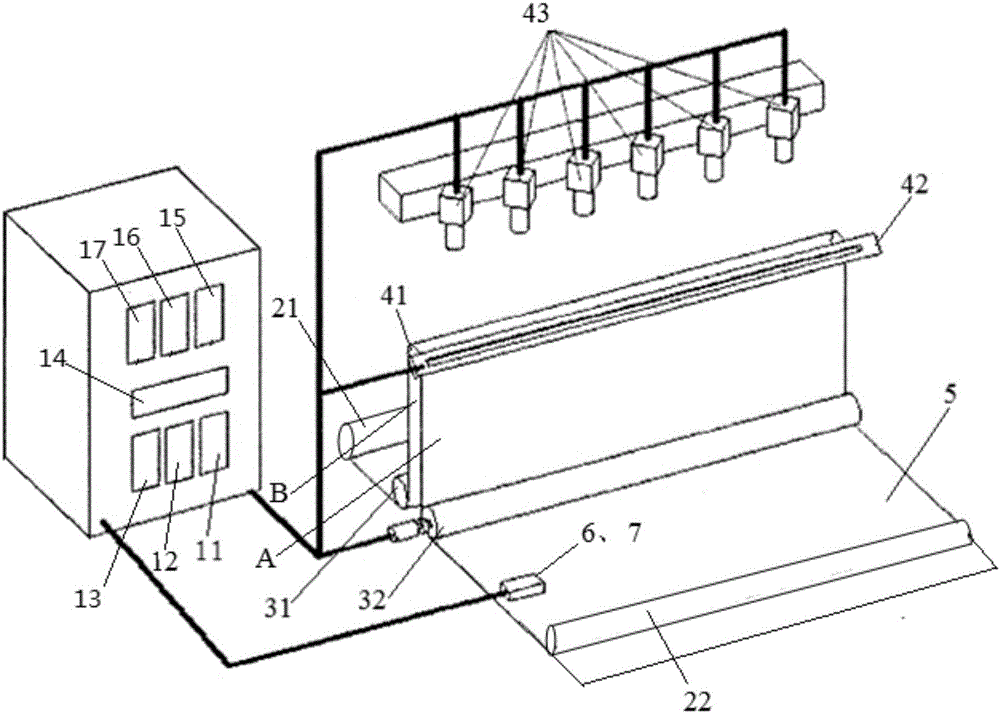

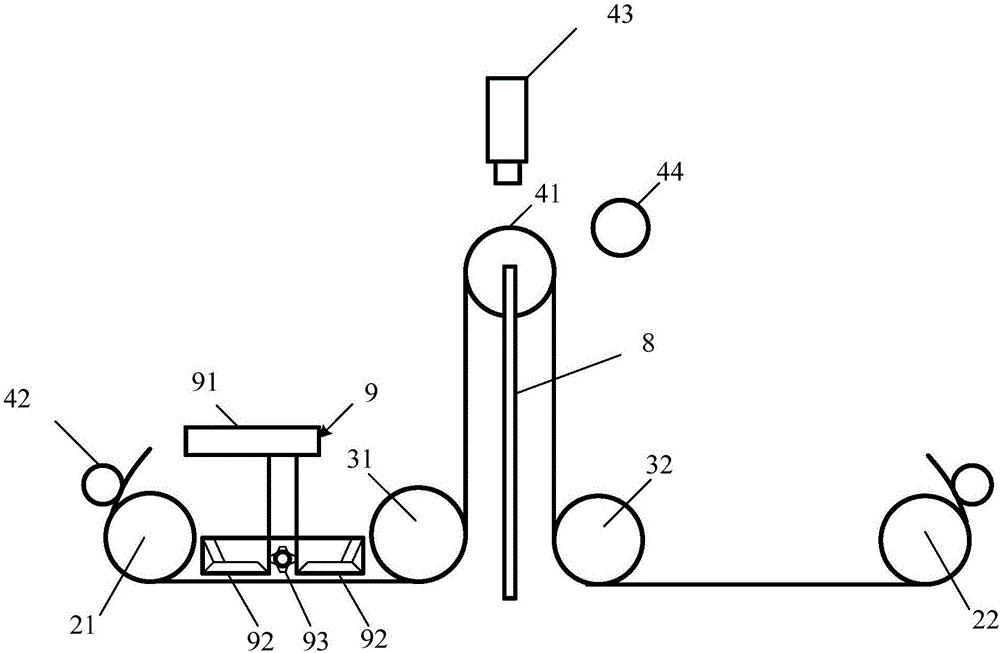

[0049] Such as figure 1 As shown, the friction cloth aging equipment of the present embodiment comprises:

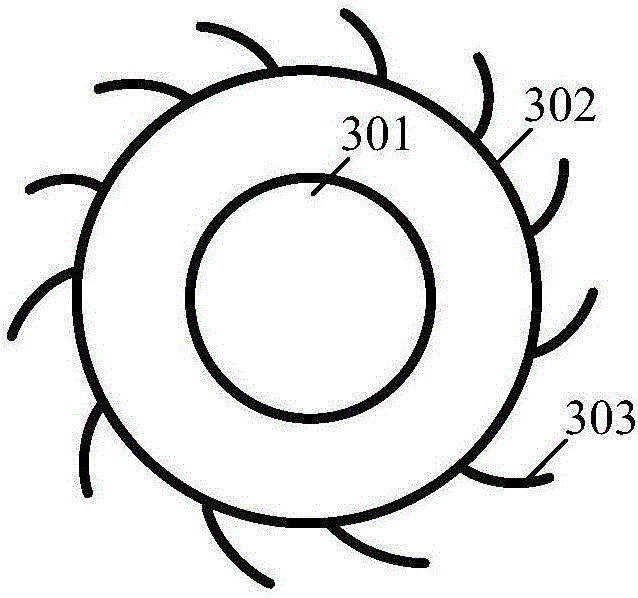

[0050] The surface is provided with a first carding roll 31 and a second carding roll 32 with a carding structure, and the first carding roll 31 and the second carding roll 32 are separated by a preset distance;

[0051] The first driving roller 21 and the second driving roller 22 that are positioned at the same level with the first combing roller 31 and the second combing roller 32, wherein the first driving roller is set 21 on the side of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com