A three-dimensional piezoelectric driven micromirror adjustment device

A technology for driving micromirrors and adjusting devices, applied in optical components, instruments, optics, etc., can solve the problems of no relevant description, difficult to locate successfully at one time, insufficient adaptability, etc., to achieve large displacement adjustment and realize multiple degrees of freedom. Adjustable and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

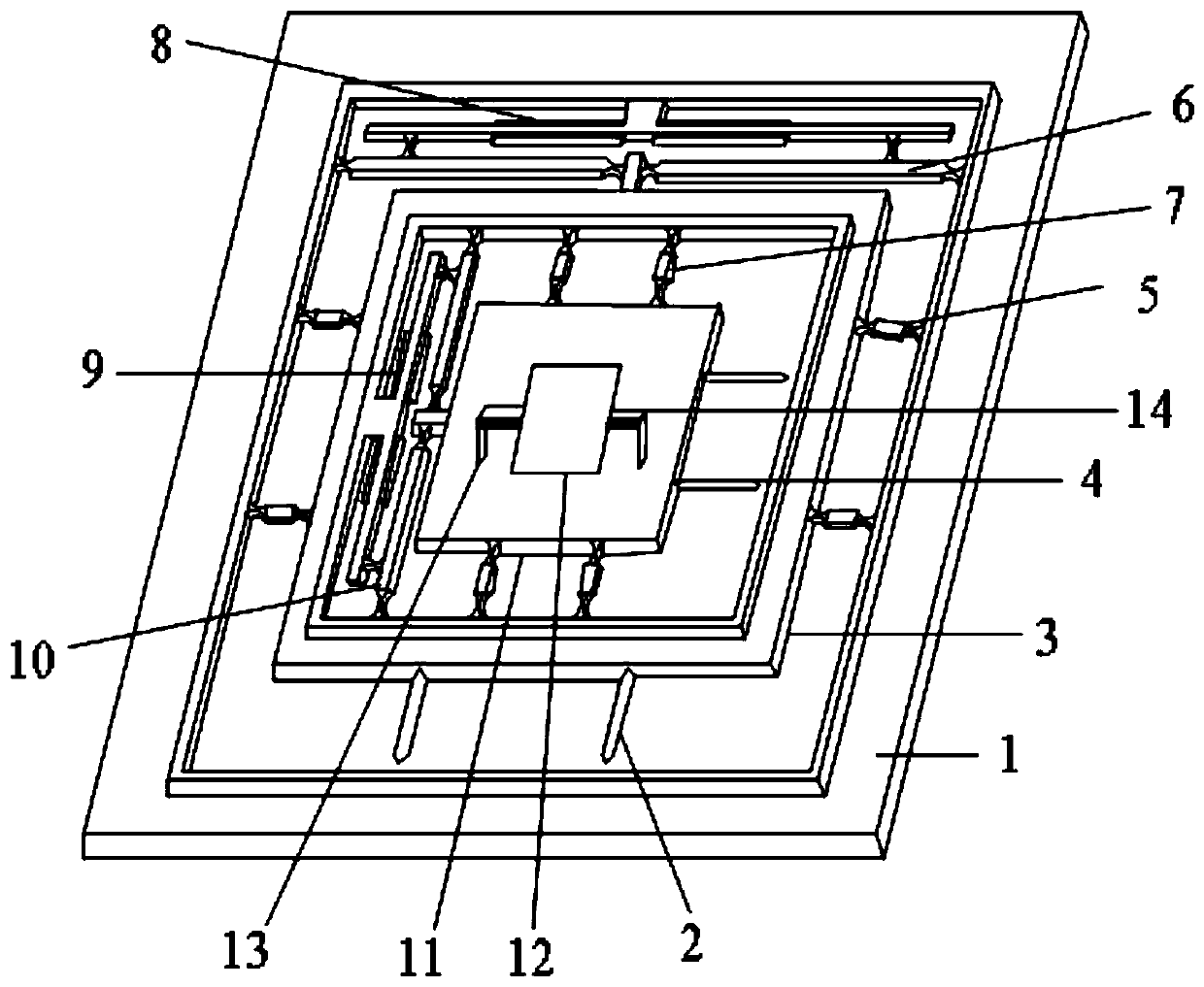

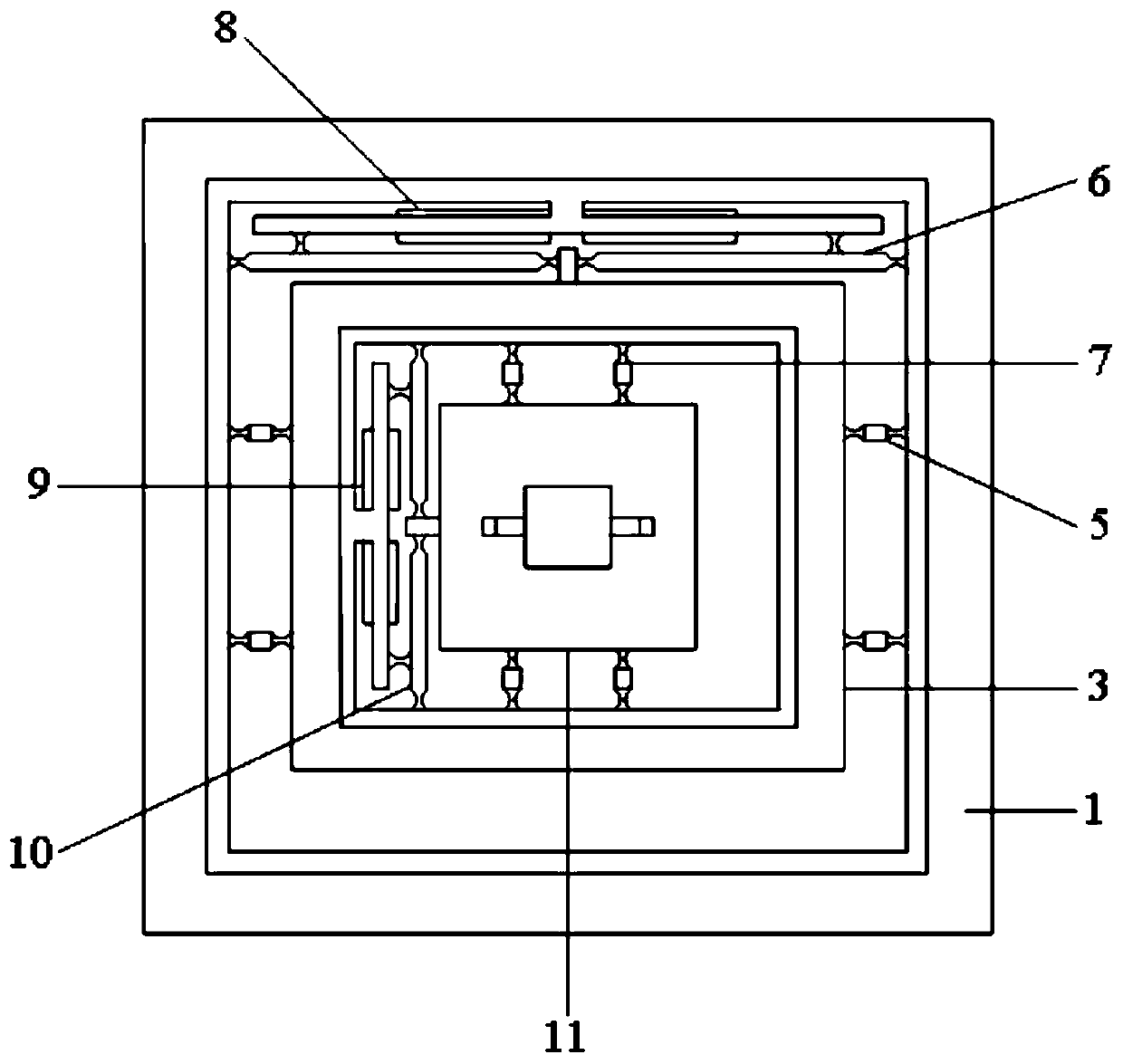

[0029] combine figure 1 , a three-dimensional piezoelectric drive micromirror adjustment device of the present invention includes an X-direction displacement adjustment platform, a Y-direction displacement adjustment platform, a Z-direction displacement adjustment mechanism, an X-direction piezoelectric film driver, a Y-direction piezoelectric film driver, and a Z-direction Piezoelectric film drivers, micromirrors, etc. The X-direction displacement adjustment includes an X-direction displacement amplification mechanism 10 , an X-direction flexible hinge guide mechanism 7 , an X-direction displacement adjustment platform 11 , and an X-direction piezoelectric film driver 9 symmetrically arranged about the central axis of the Y-direction displacement adjustment platform 3 in the X direction. The Y-direction displacement adjustment includes a Y-direction displacement amplification mechanism 6 , a Y-direction flexible hinge guide mechanism 5 , a Y-direction displacement adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com