An online rapid measurement device and method for large-aperture grating damage

A large-aperture grating and measuring device technology, which is applied in the direction of measuring devices, optical instrument testing, and machine/structural component testing, can solve time-consuming problems and achieve high sensitivity, fast measurement speed, and optimized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

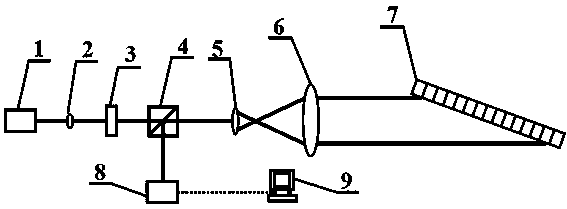

[0033] Such as figure 1 , Figure 2a with Figure 2b As shown, the online rapid measurement device for large-aperture grating damage of this embodiment includes a laser 1, a collimator lens 2, a half-wave plate 3, a polarization beam splitter 4, a first lens 5, a second lens 6, and a large Aperture grating 7, imaging system 8, data processing system 9,

[0034] The linearly polarized light beam emitted by the laser 1 is collimated by the collimator lens 2 into a parallel light beam. After passing through the half-wave plate 3, the parallel light beam passes through the polarization beam splitter 4 with high transmittance, and after passing through the polarization beam splitter 4 The transmitted light beam passes through the beam expansion system formed by the first lens 5 and the second lens 6 in turn to expand the beam diameter. The expanded beam is incident on the large-aperture grating 7 at the Littrow angle. The diffracted light will return along the original path, pass thr...

Embodiment 2

[0045] Such as figure 1 As shown, the online rapid measurement device for large-aperture grating damage of this embodiment includes a laser 1, a collimator lens 2, a half-wave plate 3, a polarization beam splitter 4, a first lens 5, a second lens 6, and a large Aperture grating 7, imaging system 8, data processing system 9,

[0046] The linearly polarized light beam emitted by the laser 1 is collimated by the collimator lens 2 into a parallel light beam. After passing through the half-wave plate 3, the parallel light beam passes through the polarization beam splitter 4 with high transmittance, and after passing through the polarization beam splitter 4 The transmitted light beam passes through the beam expansion system formed by the first lens 5 and the second lens 6 in turn to expand the beam diameter. The expanded beam is incident on the large-aperture grating 7 at the Littrow angle. The diffracted light will return along the original path, pass through the second lens 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com