Non-contact measuring method for overhead conductor diameter and cable standard board

An overhead wire and measurement method technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as difficulty in visual inspection of high-altitude cables, and achieve the effects of easy problem solving, easy determination, and rapid comparison.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

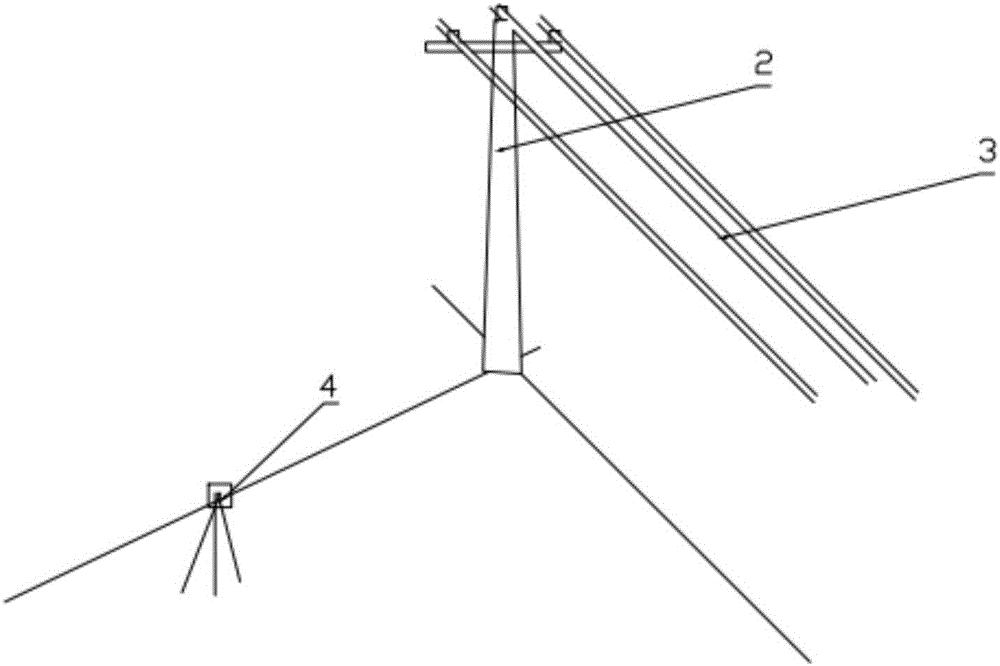

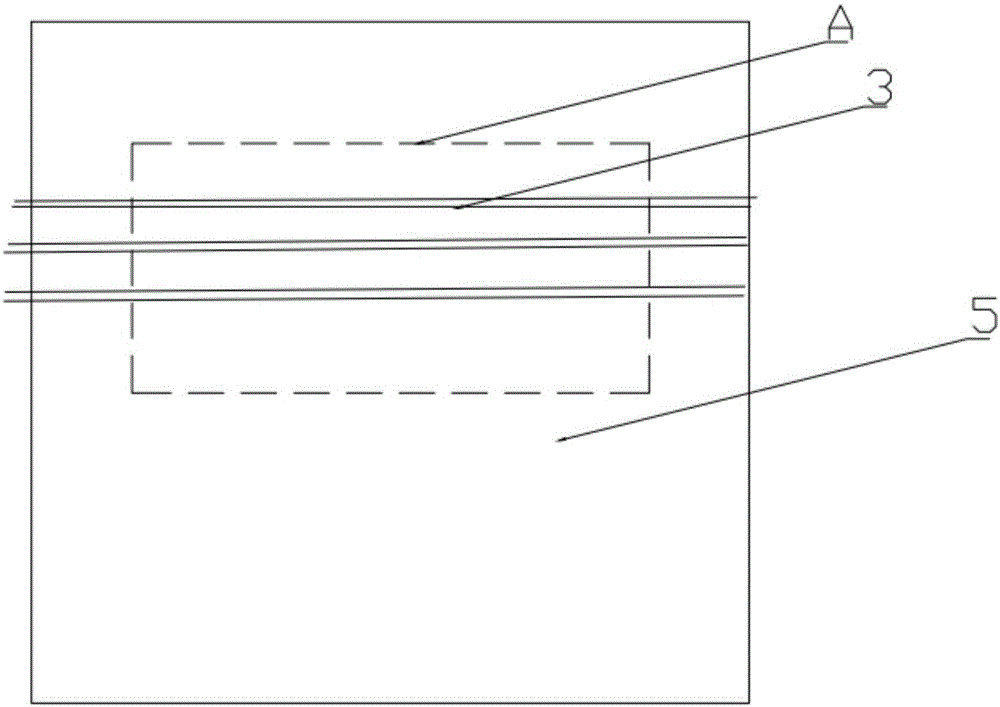

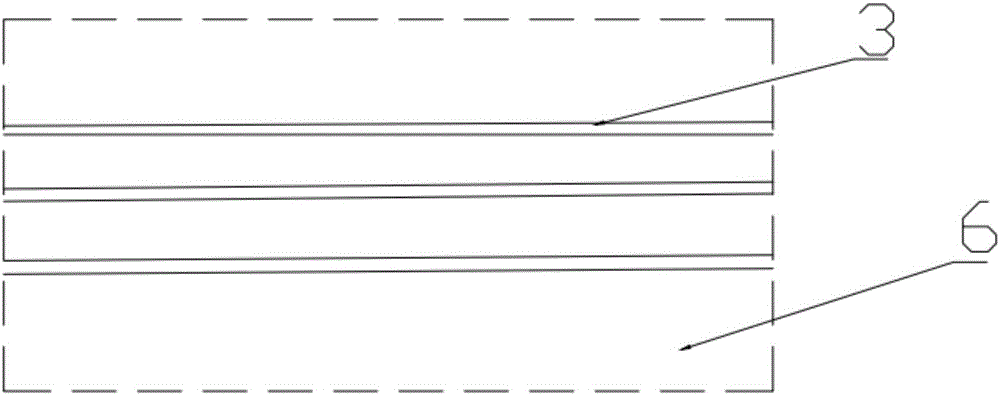

[0038] Such as Figure 1~5 As shown, a non-contact measurement method for the wire diameter of an overhead wire includes a camera 4 and a cable standard plate 1, and the cable standard plate 1 includes a standard plate body, on which a plurality of The standard cable section 1-2 corresponding to the standard cable, the measurement steps are as follows:

[0039] (1) Place the cable standard plate 1 at a standard distance from the camera 4, lock the focal length of the camera to take pictures, and form a standard comparison picture in the camera; the standard comparison picture is consistent with the cable standard plate 1, and no longer repeat.

[0040] (2) Near the cable to be tested, select a position suitable fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com