Modular manufacturing method for heating furnace and heating furnace manufactured through method

A manufacturing method and heating furnace technology, which is applied in the modular manufacturing of heating furnaces and in the field of heating furnace manufacturing, can solve the problems of high labor costs, achieve the effects of reducing manufacturing costs, improving manufacturing quality, and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

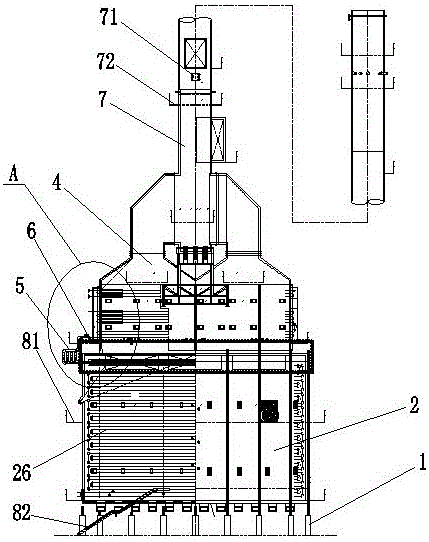

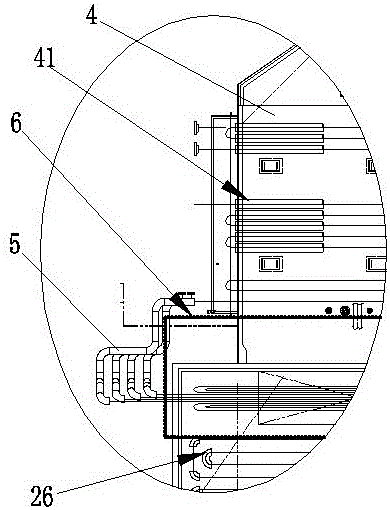

[0069] Description of icon numbers: base 1, furnace cavity module 2, furnace bottom module 21, furnace roof module 22, inner wall 23, outer wall 24, end wall 25, radiation pipe 26, connecting steel between inner walls 3, convection module group 4 , convection tube bundle 41, oil transfer line 5, radiation to convection flue 6, chimney 7, inspection port 71, inspection platform 72, maintenance platform 81, ladder 82.

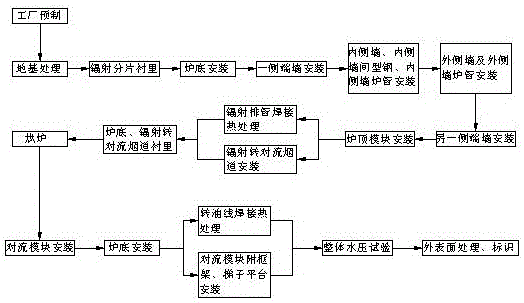

[0070] Such as figure 1 Shown is the flowchart of the present invention,

[0071] A modular manufacturing method for a heating furnace, comprising the following steps:

[0072] Step 1. Factory prefabrication: each module and radiation slice are factory prefabricated;

[0073] Step 2. Foundation treatment: Process the base according to the design drawings. After the foundation maintenance is qualified, carry out scribing and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com