Phosphate preparation device with high drying strength

A technology of drying strength and preparation equipment, which is applied in the direction of drying gas arrangement, local agitation dryer, static material dryer, etc., and can solve the problem of uneven dispersion of potassium dihydrogen phosphate and uneven dispersion of potassium dihydrogen phosphate crystals, etc. problems, to achieve the effect of high drying strength, large dispersion and increased swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

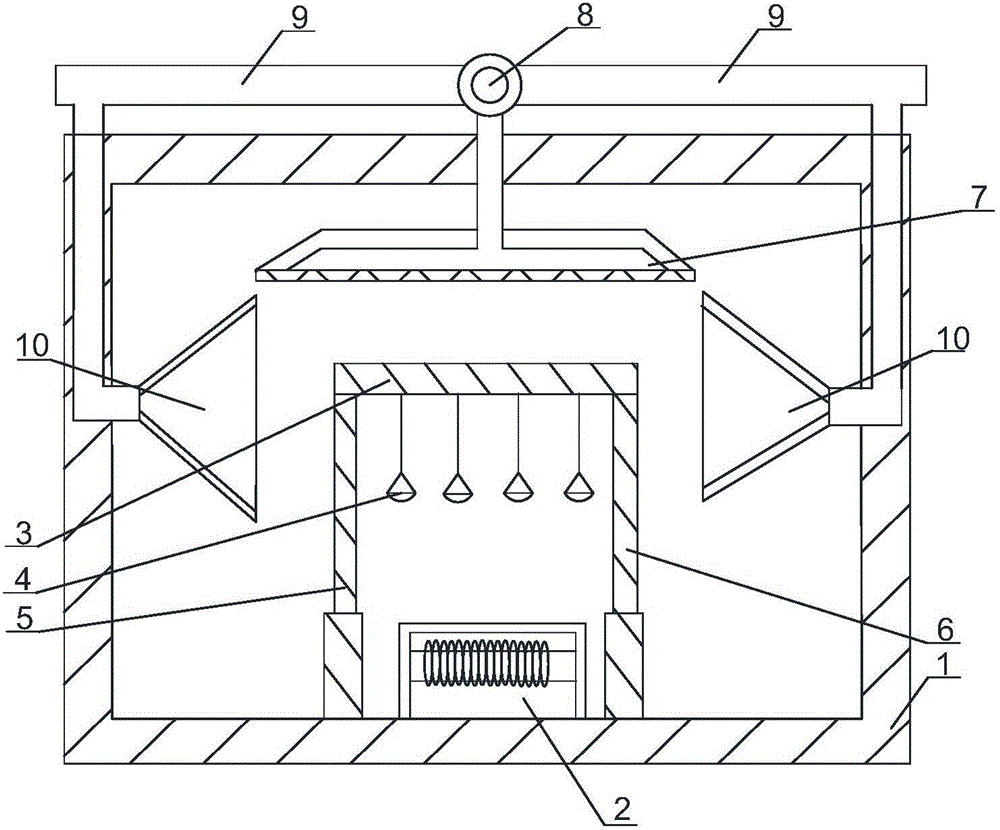

[0022] like figure 1 As shown, the phosphate preparation device with high drying strength of the present invention includes a drying box 1, a hot air blower 2 is installed at the inner bottom of the drying box 1, and a fixed column 3 is installed horizontally above the hot air blower 2. The fixed column 3 There are a plurality of drying bags 4 connected to the lower part, the drying bags 4 are located between the hot air blower 2 and the fixed column 3, the wind direction of the hot air blower 2 faces the drying bag 4, and one end of the fixed column 3 is connected to the first telescopic rod 5, fixed The other end of the column 3 is connected with a second telescopic rod 6, and the lower ends of the first telescopic rod 5 and the second telescopic rod 6 are fixed on the inner bottom of the drying box 1, and an exhaust fan is installed on the drying box 1 above the fixed column 3 7. The air outlet of the exhaust fan 7 is located directly above the fixed column 3 . An exhaust ...

Embodiment 2

[0025] Based on Embodiment 1, the upper end of the exhaust fan 7 is connected with a circulating pump 8, and both ends of the circulating pump 8 are connected with an air outlet pipe 9, and the air outlet end of the air outlet pipe 9 passes through the same side From the side wall of the drying box 1 to the interior of the drying box 1 , the air outlet end of the air outlet pipe 9 is connected with an air outlet cover 10 , and the air outlet cover 10 is located on both sides of the drying bag 4 . All the pipe walls of the air outlet pipes 9 are equipped with carbon fiber heaters. The circulation pump circulates the hot air from the hot air blower. The exhaust fan pumps the hot air from the hot air blower upwards. The hood enters the inside of the drying box to further heat and dry the potassium dihydrogen phosphate inside the drying bag. The circulation pump is also the air circulation of the hot air blower, which not only saves costs, but also strengthens the drying of potass...

Embodiment 3

[0027] Based on the above embodiment, the first telescopic rod 5 is controlled by a first motor, and the second telescopic rod 6 is controlled by a second motor. The optimal movement mode of the first telescopic rod and the second telescopic rod is: the first telescopic rod and the second telescopic rod move in the opposite direction. If it is assumed that the rotation direction of the first motor is positive, then the rotation direction of the second motor is In the opposite direction, when the first telescopic rod moves upward, the second telescopic rod moves downward, the vibration effect is better, the vibration effect is good, the shaking degree of the drying bag is greater, and the dispersion of potassium dihydrogen phosphate inside the drying bag Greater degree, no need for secondary granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com