Single-channel combustor for decomposition furnace

A single-channel, burner technology, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve the problem of secondary pollution caused by ammonia escape, achieve flexible and fast coordination, reduce production costs, reduce heat consumption and Effects of NOx Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

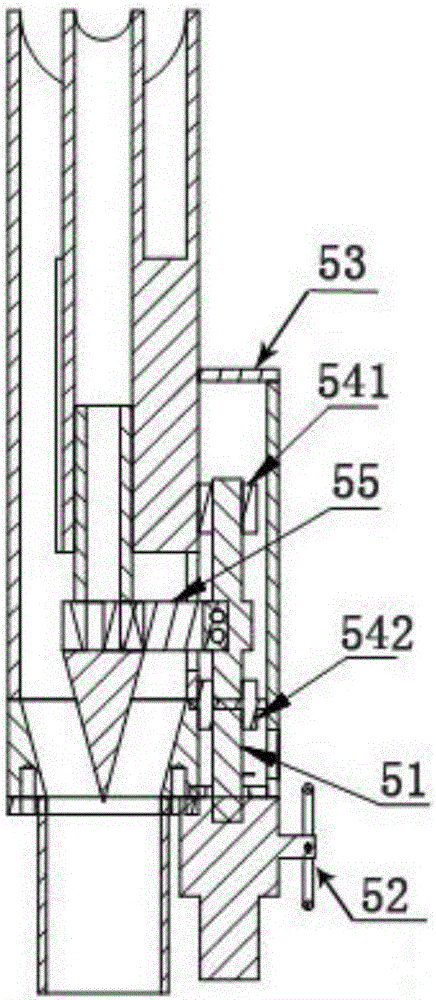

[0030] A single-channel burner for a calciner, which is composed of an outer pipe 1, a throat pipe 2 and a fuel inlet connection pipe 3. After the outer pipe 1, throat pipe 2 and fuel inlet connection pipe 3 are connected in sequence, there is a through fuel pipe inside. The connection between the pipe 1, the throat pipe 2 and the fuel inlet pipe 3 can be welded, threaded or bolted; The inner diameter gradually increases, and it has an isosceles trapezoidal shape in section along the axis. The single channel burner also includes an inner tube 6, the inner tube 6 is concentrically arranged in the outer tube 1, a support 11 is provided between the outer tube 1 and the inner tube 6, and the support 11 is used to secure the inner tube 6 The supporting member 11 can be cast together with the outer tube 1 and the inner tube 6, or can be fixed together after being manufactured separately. There are three support members 11, and the three support members are arranged in three places,...

Embodiment 2

[0033] A single-channel burner for a calciner, which is composed of an outer pipe 1, a throat pipe 2 and a fuel inlet connection pipe 3. After the outer pipe 1, throat pipe 2 and fuel inlet connection pipe 3 are connected in sequence, there is a through fuel pipe inside. The connection between the pipe 1, the throat pipe 2 and the fuel inlet connection pipe 3 can be welded, threaded or bolted; the fuel pipeline in the throat pipe 2 is dumbbell-shaped, and it consists of two circular platforms and a cylindrical tube in the middle of the two circular platforms. composition. The single channel burner also includes an inner tube 6, the inner tube 6 is concentrically arranged in the outer tube 1, a support 11 is provided between the outer tube 1 and the inner tube 6, and the support 11 is used to secure the inner tube 6 The supporting member 11 can be cast together with the outer tube 1 and the inner tube 6, or can be fixed together after being manufactured separately. There are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com