Centrifugal compressor with double pressure ratios

A centrifugal compressor and high-pressure technology, applied in the field of compressors, can solve the problems of adding centrifugal compressors, the number of centrifugal compressors cannot be increased at will, and the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

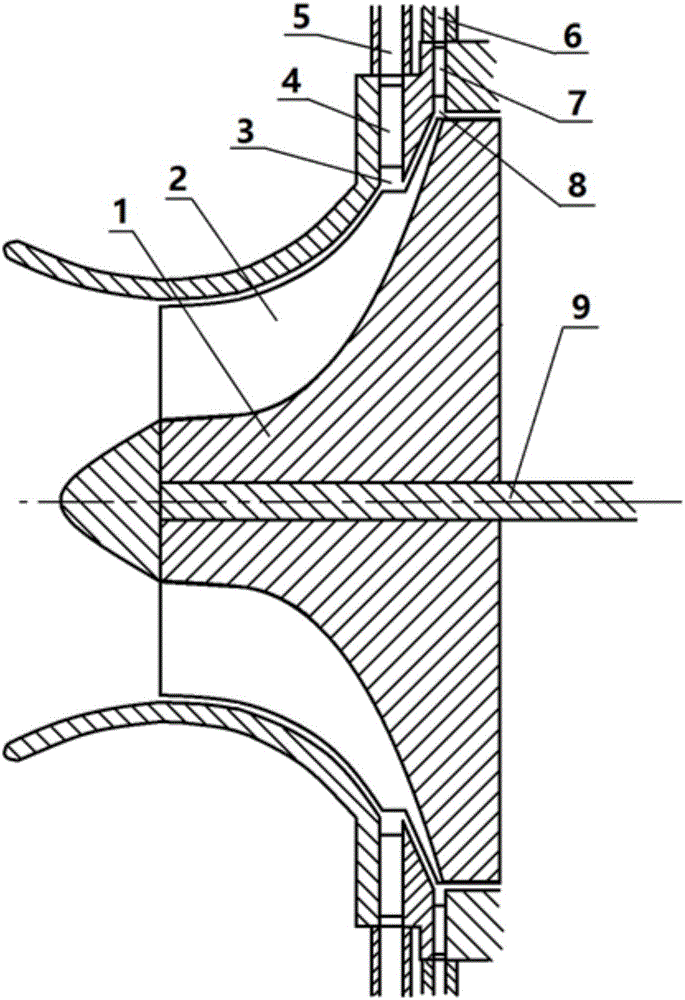

[0015] exist figure 1 In the shown structure, the dual pressure ratio centrifugal compressor provided by the present invention includes a rotor and a stator. The rotor is composed of a main shaft 9 and an impeller sleeved on the main shaft 9. The impeller includes a blade 2 and a disc 1, and the chord length of the blade is The 3 / 4 part is designed as a stepped bending structure (in a stepped shape). When the centrifugal compressor is working, the compressed part of the air flow flows out from the bending part. Two annular outlets with different radii are set on the circumference of the impeller. Among them, the radius The large annular outlet is located at the end of the impeller blade, and its air velocity and pressure are relatively high, which is the high-pressure outlet 8. The annular outlet with a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com