A method for cross-linking modification of aliphatic polycarbonate

A polycarbonate, cross-linking modification technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problem of changing the flexibility of the main chain of aliphatic polycarbonate, the difficulty of controlling the degree of polycarbonate cross-linking, and the existence of safety hazards and other problems, to achieve good application prospects, low cost of raw materials, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

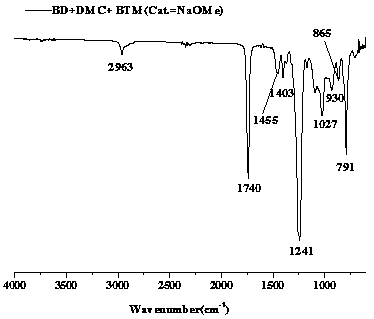

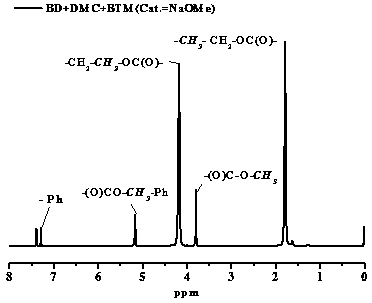

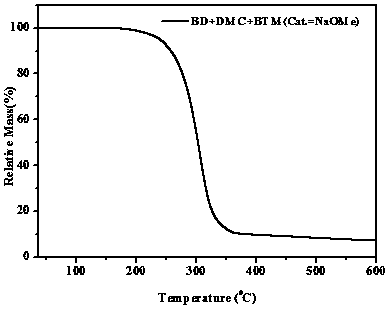

[0022] A method for cross-linking modification of aliphatic polycarbonate, is characterized in that, comprises the following steps:

[0023] 1,4-butanediol (273mg, 3mmol), dimethyl carbonate (290mg, 10mmol), 1,3,5-benzenetrimethanol (168mg, 1mmol) and sodium methoxide (2.701mg, 0.05mmol) were added to 50ml Fill the polymerization tube with nitrogen gas and polymerize in two steps. The first step is at 120°C for 9 hours; the second step is at 210°C for 6 hours at 10KPa; acetic acid and chloroform are washed in sequence and vacuum-dried to obtain crosslinking Type aliphatic carbonate 0.80g. The swelling rate is 1190%.

Embodiment 2

[0025] A method for cross-linking modification of aliphatic polycarbonate, is characterized in that, comprises the following steps:

[0026] 1,4-pentanediol (273mg, 3mmol), dimethyl carbonate (290mg, 10mmol), 1,3,5-benzenetrimethanol (84mg, 0.5mmol) and sodium methoxide (2.701mg, 0.05mmol) were added to Fill a 50ml polymerization tube with nitrogen gas and polymerize in two steps. The first step is at 120°C for 9h; the second step is at 190°C for 6h at 10KPa; the acetic acid and chloroform are washed in sequence and vacuum-dried to obtain cross-linked Joint type aliphatic carbonate 0.75 g; swelling rate 1429%.

Embodiment 3

[0028] A method for cross-linking modification of aliphatic polycarbonate, is characterized in that, comprises the following steps:

[0029] 1,5-hexanediol (273mg, 3mmol), dimethyl carbonate (290mg, 10mmol), 1,3,5-benzenetrimethanol (84mg, 0.50mmol) and sodium methoxide (2.701mg, 0.05mmol) were added to Fill a 50ml polymerization tube with nitrogen gas and polymerize in two steps. The first step is at 120°C for 9 hours; the second step is at 170°C for 6 hours at 10KPa. Acetic acid and chloroform were washed successively, and vacuum-dried to obtain 0.69 g of a cross-linked aliphatic carbonate. The swelling rate was 629%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com