Gas well downhole drainage and gas production tool based on integration of jet flow and vortexes

A drainage gas production and eddy current technology, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling and production, etc., can solve the problems of easy accumulation of liquid, affecting the liquid carrying capacity of gas wells, and exerting production capacity, and achieves high separation efficiency and reduced The effect of fishing workload and wellbore operation management risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to this embodiment. In order to provide the public with a thorough understanding of the present invention, specific details are specified in the following preferred embodiments of the present invention.

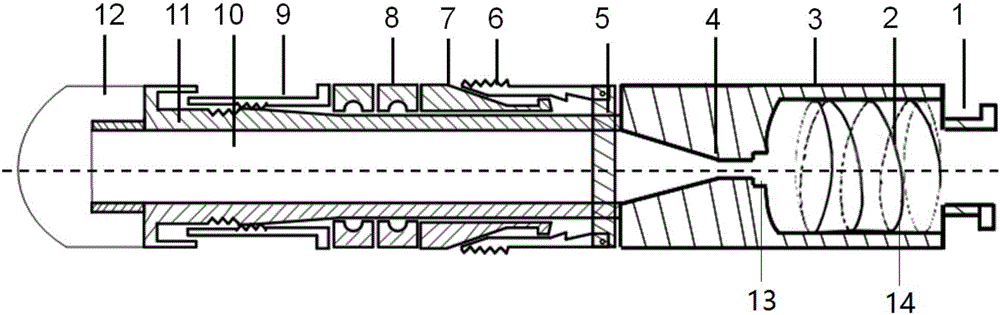

[0028] as attached figure 1 As shown, the present invention is a gas well drainage and gas recovery tool based on the integration of jet flow and vortex flow. The tool is composed of jet generator and vortex generator, mainly including salvage head 1, vortex drainage chamber 2, shell 3, jet nozzle 4, weight ring 5, slips 6, lower slip seat 7, sealing rubber ring 8 , locking device 9, jet guide tube 10, linkage mechanism 11 and sand control cover 12.

[0029] The jet flow generator includes a jet flow guiding cylinder 10, a linkage mechanism 11, slips 6 and a lower slip seat 7, the linkage mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com