Ground heating artificial stone wet sticking construction method and relevant mounting structure

A technology of artificial stone and construction method, which is applied in the direction of building structure, floor, construction, etc., and can solve the problems of wet paste materials such as hollowing, falling off, and large temperature stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

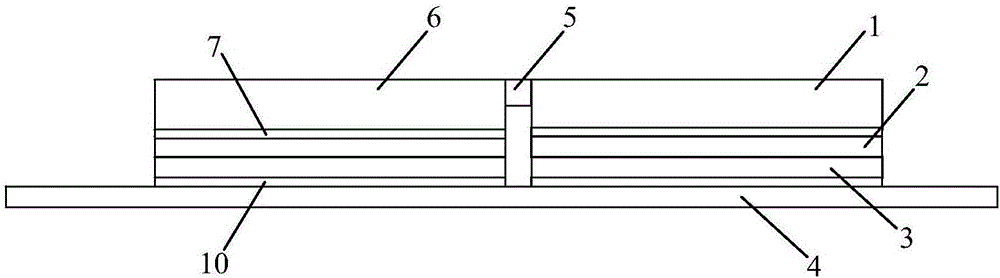

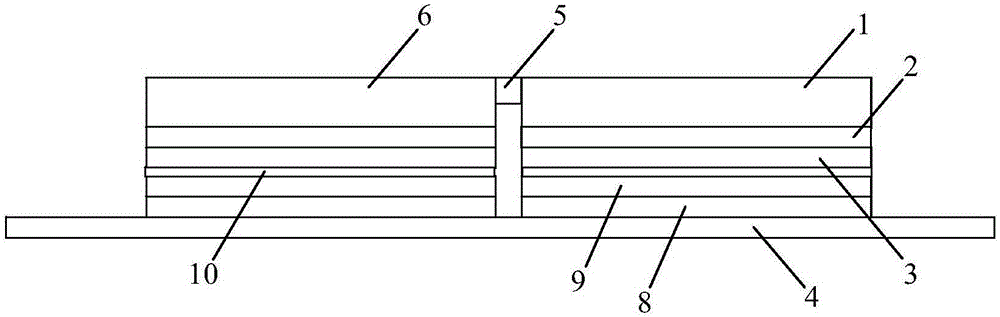

Image

Examples

Embodiment 1

[0066] 1. Apply artificial stone waterproof adhesive

[0067] Artificial stone 6 adopts large flower-shaped artificial granite, artificial stone waterproof adhesive adopts AD-8011 artificial stone waterproof adhesive (Shanghai Aidi Technology Development Co., Ltd.), artificial stone alkali-resistant reinforced net 7 adopts a specification of 145g / m 2 Alkali-resistant glass fiber mesh cloth, also can use specifications greater than 145g / m 2 Alkali-resistant fiberglass mesh. The batch coating of artificial stone waterproof adhesive is recommended to be completed in the stone slab processing factory. The specific operation steps are as follows.

[0068] 1.1 Bonding surface treatment

[0069] Before batch coating, use brushes, spatulas and other tools to clean the dust, dirt, oil stains, resin backing, etc. on the bonding surface of the artificial granite, so as to keep the bonding surface of the artificial granite clean.

[0070] 1.2 The deployment of AD-8011 artificial stone ...

Embodiment 2

[0091] 1. Apply artificial stone waterproof adhesive

[0092] Artificial stone 6 adopts fine aggregate artificial granite, and the artificial stone waterproof adhesive adopts AD-8011 artificial stone waterproof adhesive (Shanghai Aidi Technology Development Co., Ltd.). The batch coating of artificial stone waterproof adhesive is recommended to be completed in the stone slab processing factory. The specific operation steps are as follows.

[0093] 1.1 Bonding surface treatment

[0094] Before batch coating, use brushes, spatulas and other tools to clean the dust, dirt, oil stains, resin back net, etc. on the bonding surface of fine aggregate artificial granite, so as to keep the bonding surface of fine aggregate artificial granite clean.

[0095] 1.2 The deployment of AD-8011 artificial stone waterproof adhesive

[0096] Mix the liquid and powder of AD-8011 artificial stone waterproof adhesive at a ratio of 1:2 (mass ratio), and mix well with an electric mixer (when stirring,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com