Fiber cloth outside steel pipe inner filling coral concrete combined structural column

A technology of outsourcing steel pipes and combined structures, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of steel corrosion, small working surface, large evaporation, etc., to improve the compressive strength and material ductility, enhance corrosion resistance, Enhanced durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

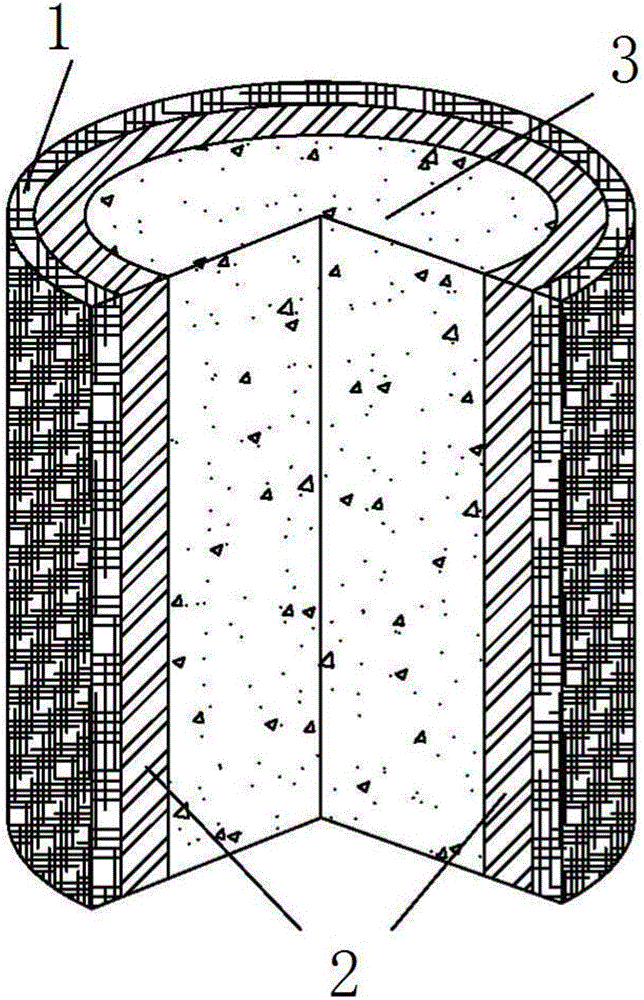

[0020] Such as figure 1 As shown, the present invention is composed of fiber cloth 1, steel pipe 2 and coral concrete 3, the steel pipe is wrapped with fiber cloth, and the steel pipe is filled with coral concrete.

[0021] The strength grade of coral concrete is prepared according to the strength grade of C40 ordinary concrete. The mix ratio is designed, and the research conclusion of the optimization research of the mix ratio of the material orthogonal test is: Rice 320kg, 1020kg, 450kg, 230kg are configured, (the mass error of a single proportioning component is not more than 1%). The cement is 42.5# sulfate cement; the fineness modulus of coral sand fine aggregate after sieving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com