Construction method of flow plastic-state sludge sand stratum diaphragm wall

A construction method and silt technology, applied in sheet pile wall, foundation structure engineering, earth mover/shovel, etc., can solve the problem that the ground connection wall occupies the used space, the reinforcement cage cannot be installed smoothly, and the land connection is occupied. Wall construction axis and other issues, to achieve the effect of improving the brushing effect, improving the construction progress of the trough, and ensuring the verticality of the trough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

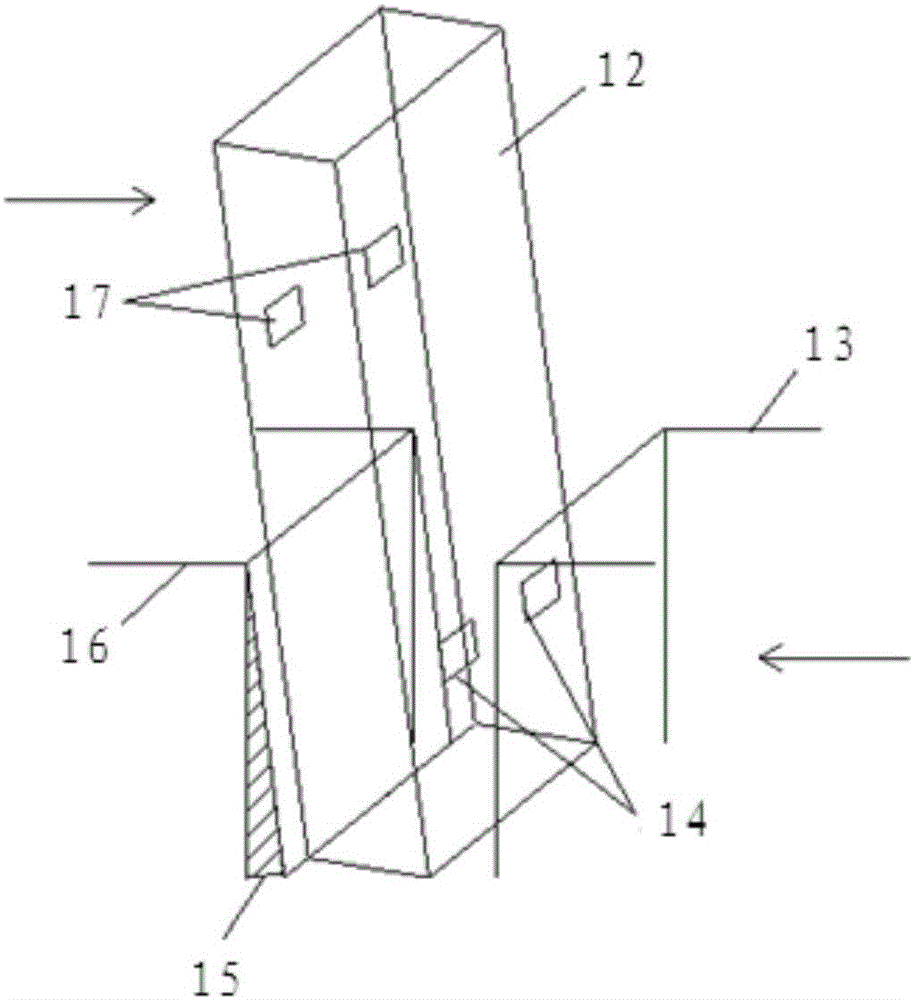

[0050] The invention provides a construction method for a ground connection wall in a flow-plastic silty sand-containing stratum, comprising:

[0051] Convective plastic muddy sandy stratum is used for trenching construction in order to form ground connection wall slots;

[0052] Carry out reinforcement cage lowering and concrete pouring construction in the slot hole to form the ground connecting wall;

[0053] Among them, the trenching construction process in the convective plastic silty sandy stratum includes the step of trenching and rectifying deviation, and the steps include:

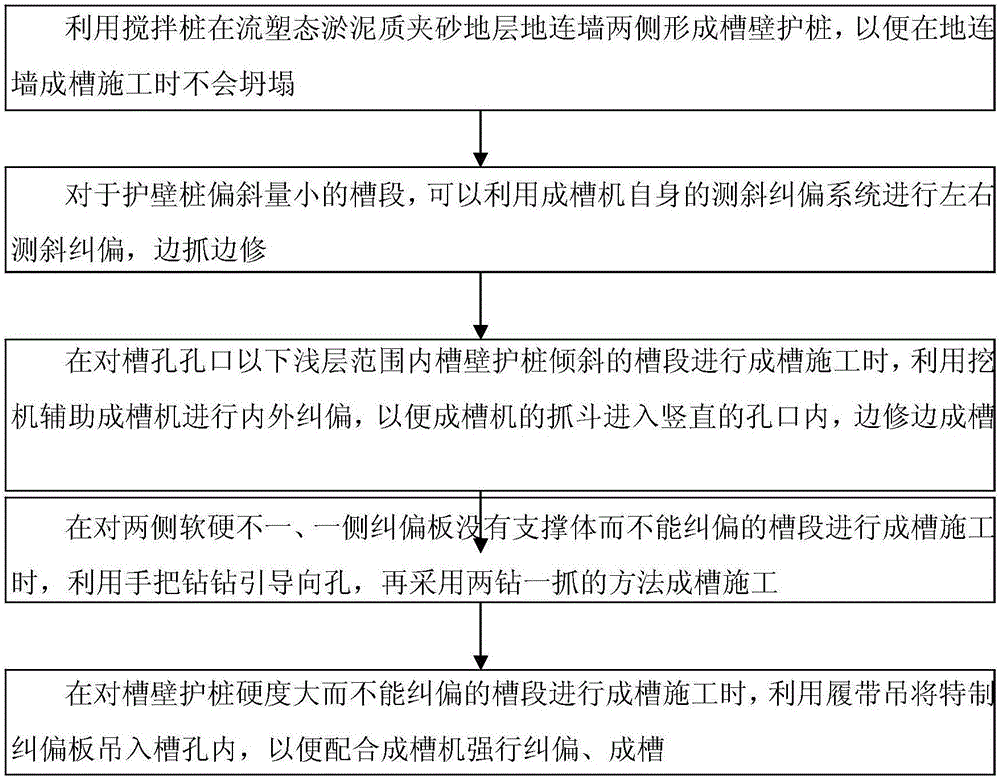

[0054] Use stirring piles to form groove wall protection piles on both sides of the ground connection wall in the flow-plastic silt sandy stratum, so that the ground connection wall will not collapse during the construction of the groove;

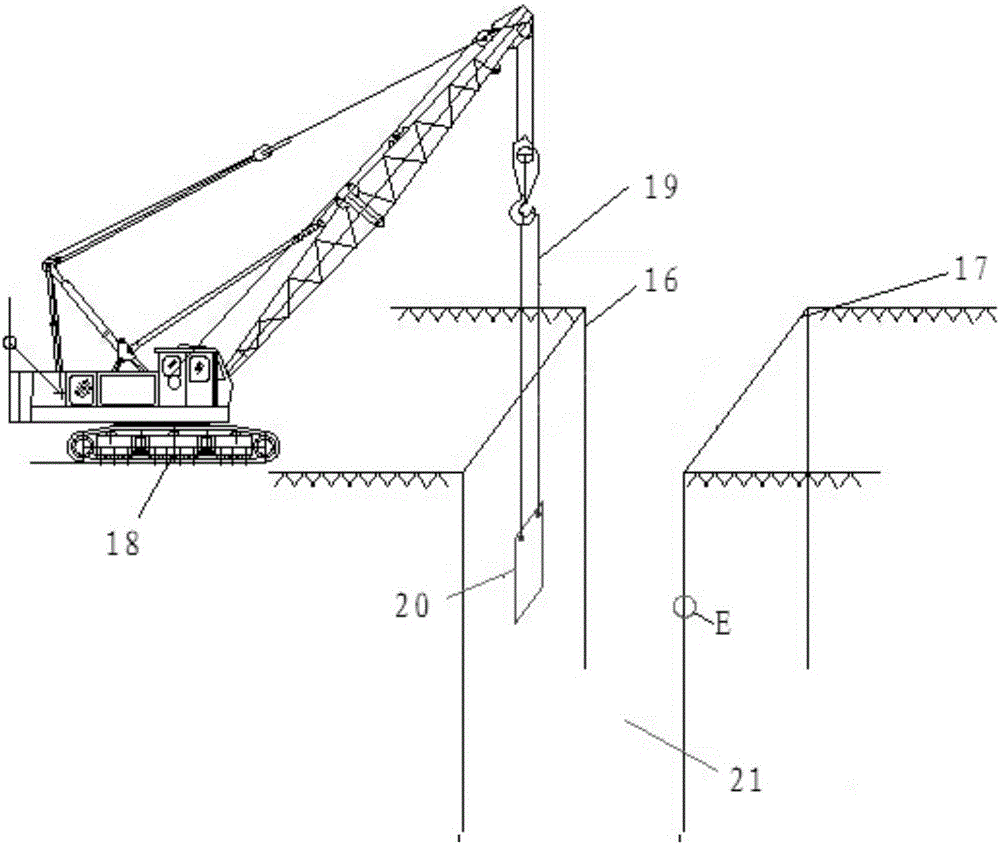

[0055]When performing groove construction on the inclined groove section of the groove wall protection pile in the shallow range below the hole opening, the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com