Method for regenerating waste oil

A technology of waste oil and sodium bentonite, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of secondary pollution and incomplete regeneration, and can prevent the oxidation of waste oil, which is beneficial to adsorption purification and purification. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

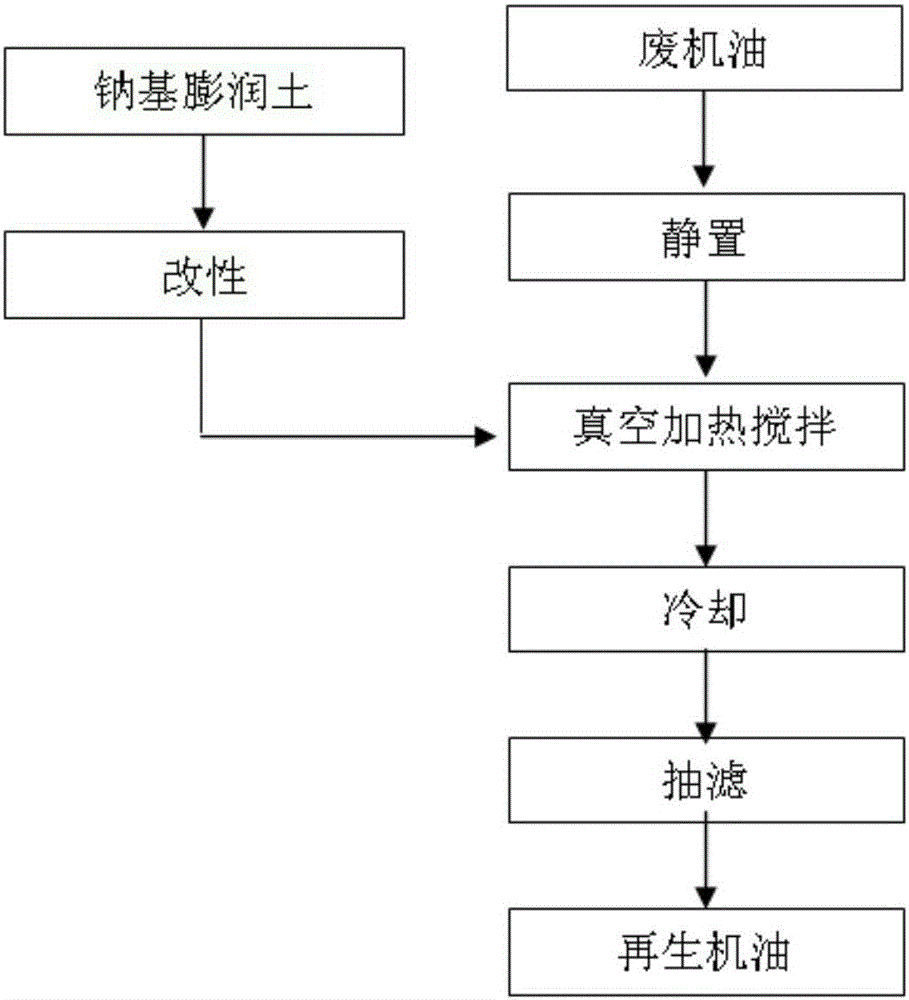

[0025] A method for regenerating waste engine oil, the steps are as follows:

[0026] 1) Take 150 g of sodium-based bentonite particles, and obtain a powder with a diameter of 200 mesh after crushing and screening;

[0027] 2) Take modifier cetyltrimethylammonium bromide, configure the modifier solution of solution 5g / L; Add the sodium bentonite powder of step 1) in the modifier solution, the modifier solution The pH is 7, shake on a water-bath shaker at 50°C for 4 hours, take it out and air-dry it naturally to obtain modified sodium-based bentonite powder for later use;

[0028] 3) 5L of waste engine oil was left to stand for 24 hours, and the water in the lower layer was removed to obtain the initially treated waste engine oil;

[0029] 4) Put the waste engine oil that has been preliminarily treated in step 3) in a vacuum agitator, the system pressure of the vacuum agitator is 25kpa, heat the waste engine oil to 110°C, stir the waste engine oil continuously under vacuum con...

Embodiment 2

[0031] A method for regenerating waste engine oil, the steps are as follows:

[0032] 1) Take 150 g of sodium-based bentonite particles, and obtain a powder with a diameter of 200 mesh after crushing and screening;

[0033] 2) Take modifier cetyltrimethylammonium bromide, configure the modifier solution of solution 5g / L; Add the sodium bentonite powder of step 1) in the modifier solution, the modifier solution The pH is 7, shake on a water-bath shaker at 50°C for 4 hours, take it out and air-dry it naturally to obtain modified sodium-based bentonite powder for later use;

[0034] 3) 2.5L of waste engine oil was left to stand for 24 hours, and the water in the lower layer was removed to obtain the initially treated waste engine oil;

[0035] 4) Put the waste engine oil that has been preliminarily treated in step 3) in a vacuum agitator, the system pressure of the vacuum agitator is 20kpa, heat the waste engine oil to 90°C, stir the waste engine oil continuously under vacuum co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com